What cloggs it? Hop material or break material?

Do you use a sock or spyder for your hops?

If yes, what size mesh?

Sorry for the mini-hijack, storytyme.

It’s still relevant.

Back to original topic...

@mongoose33 i can’t imagine that the chilling performance suffers much from returning the wort to the kettle.

Not speaking from experience here.

Seems like you have to get the heat out of the full volume no matter where it’s directed.

The only savings I can see in my mind’s eye is that if not returning the wort to the kettle, you won’t need to pull the heat out of the kettle itself.

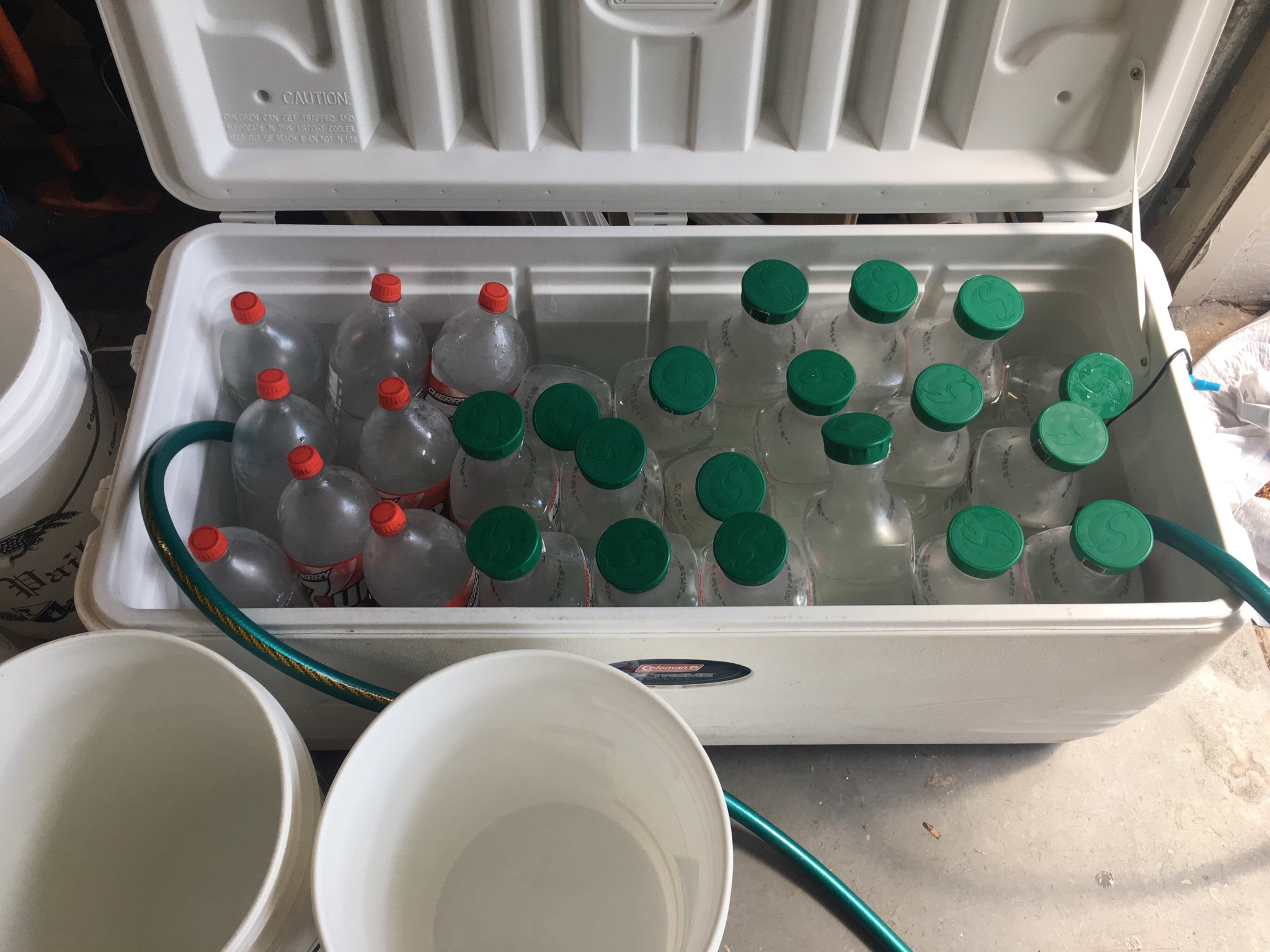

With my immersion chiller, I have to make 15 gallons of hot water to get the wort to pitching temps.

The 1st 10 gallons start out at about 85*F.

The last 5 gallons start out at about 40*F.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)