marcb

Well-Known Member

Francus said:So, when is the party?

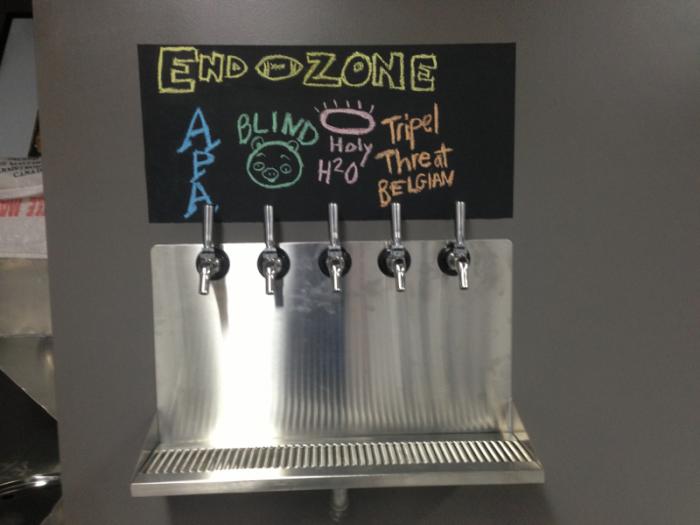

Sunday, nothing like a party at the house as a forcing function for getting stuff done!

Francus said:So, when is the party?

marcb said:Sunday, nothing like a party at the house as a forcing function for getting stuff done!

Tankless is live and generates 185 degree water full throttle! Amazing!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Boar Beer said:marcb

Nice looking coils they do look hard to clean and might allow unwanted bugs into your brew.

Are you going to use them to make lagers or just to control your fermentation temperature?

Great thread BTW

This is a pretty intense build. I'm curious of the size of the stir plate you were using for that 8gallon starter, if you used one at all.

Im still trying to wrap my head around the scope of this build, what sort of power/gas bills are you expecting with this setup?

marcb said:Brain is too tired for math right now! I will tally up a list and prices. I'm guessing that for the brewery with fermenters and control panel total was about 10k. Really stoked on being able to do two different beers in one brew day!

Jaybird said:Marc

What CIP pump are you using?

Cheers

Jay

MooMooBrew said:Ooo shiny. Off topic, how we'll does the garage door insulation work?

What was the basis for the position of your whirlpool port? I was looking for recommendations on placement and didn't find anything too specific. I was thinking about a quarter of the way up the tank and an inch in from the edge.

Carlscan26 said:How fast does that pre chiller filter clog?

marcb said:Hasn't yet! It's the one from brewers hardware with no extra screen. It's a pita to clean but works well.

mxstar21 said:Flip the other way so the side with 3 in fitting is on the bottom. Much easier to clean IMO. I have used mine twice; no problems either way, other than cleaning being easier with hops on the outside of strainer rather than inside. I have only used whole hops with mine, but would assume results would be the same filtering wise.

It was definitely a pain the ass to get all of the hops cleaned out of inside the strainer. Had to use a skewer to get them all out.

marcb said:Nice! Hadn't thought of that, any issues with flow with it reversed?

mkakunda said:absolutely. I've been wanting to bank yeast for a while and with my background in the lab it will be very easy. Let's all meet, chat, and grab beers