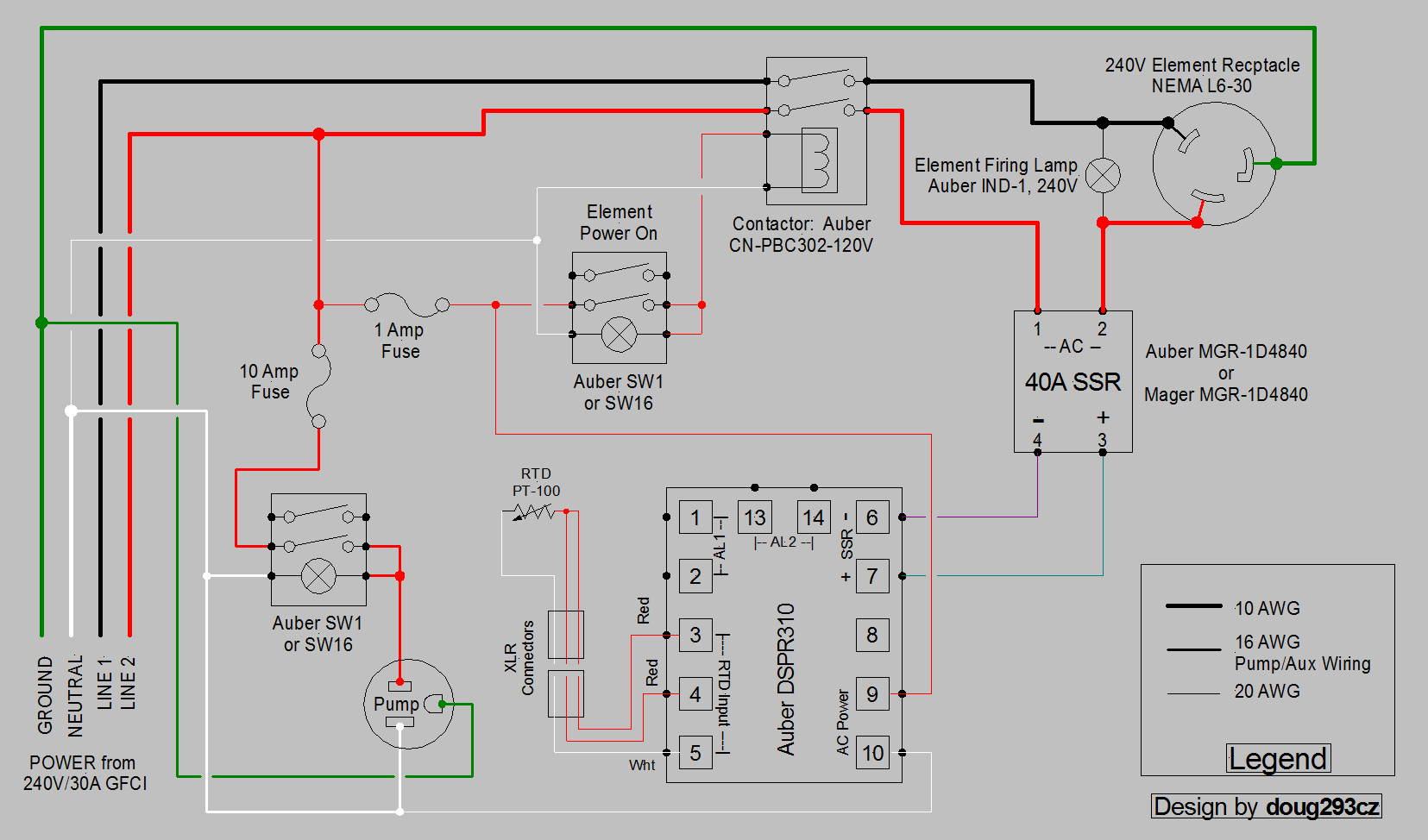

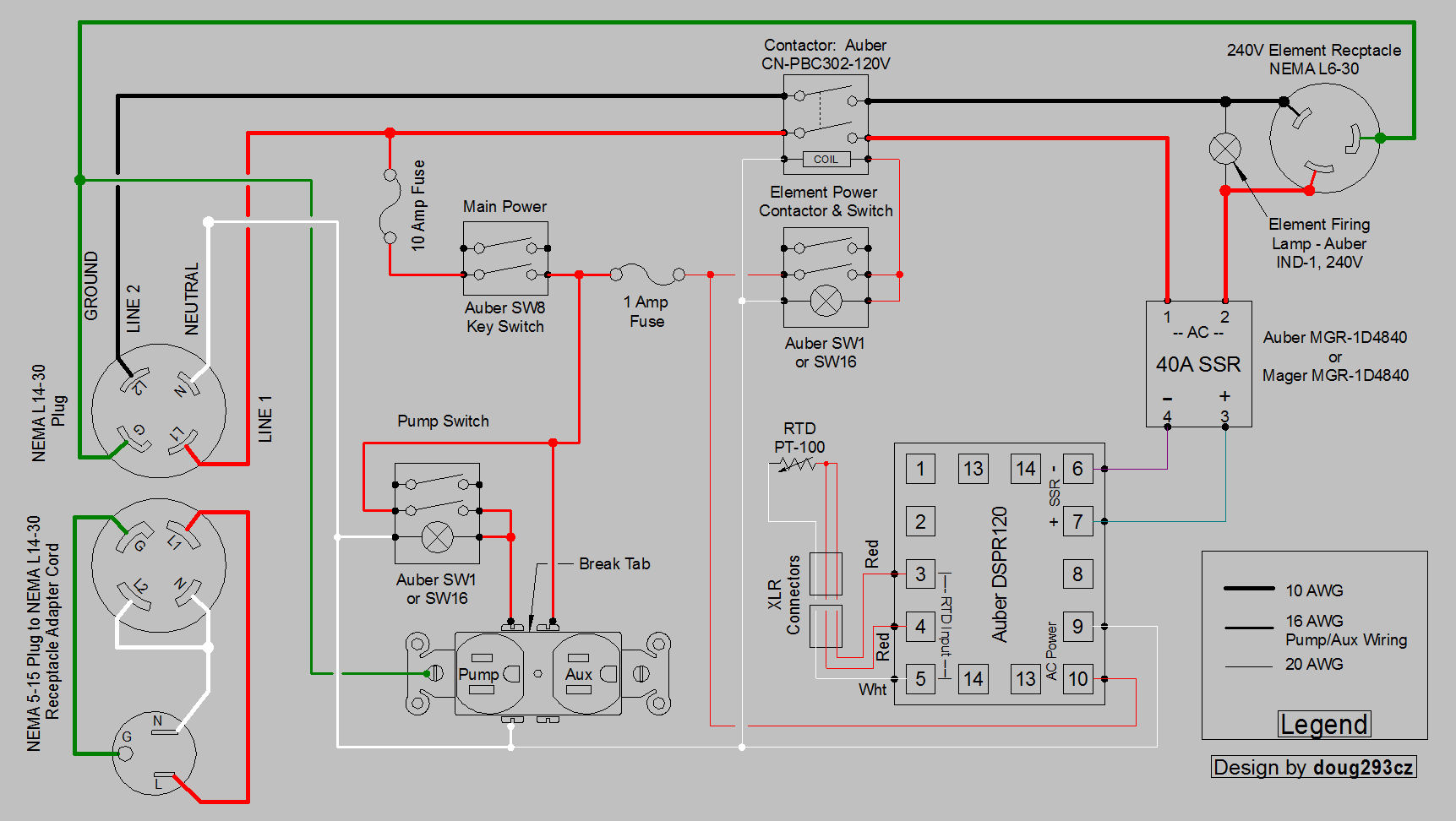

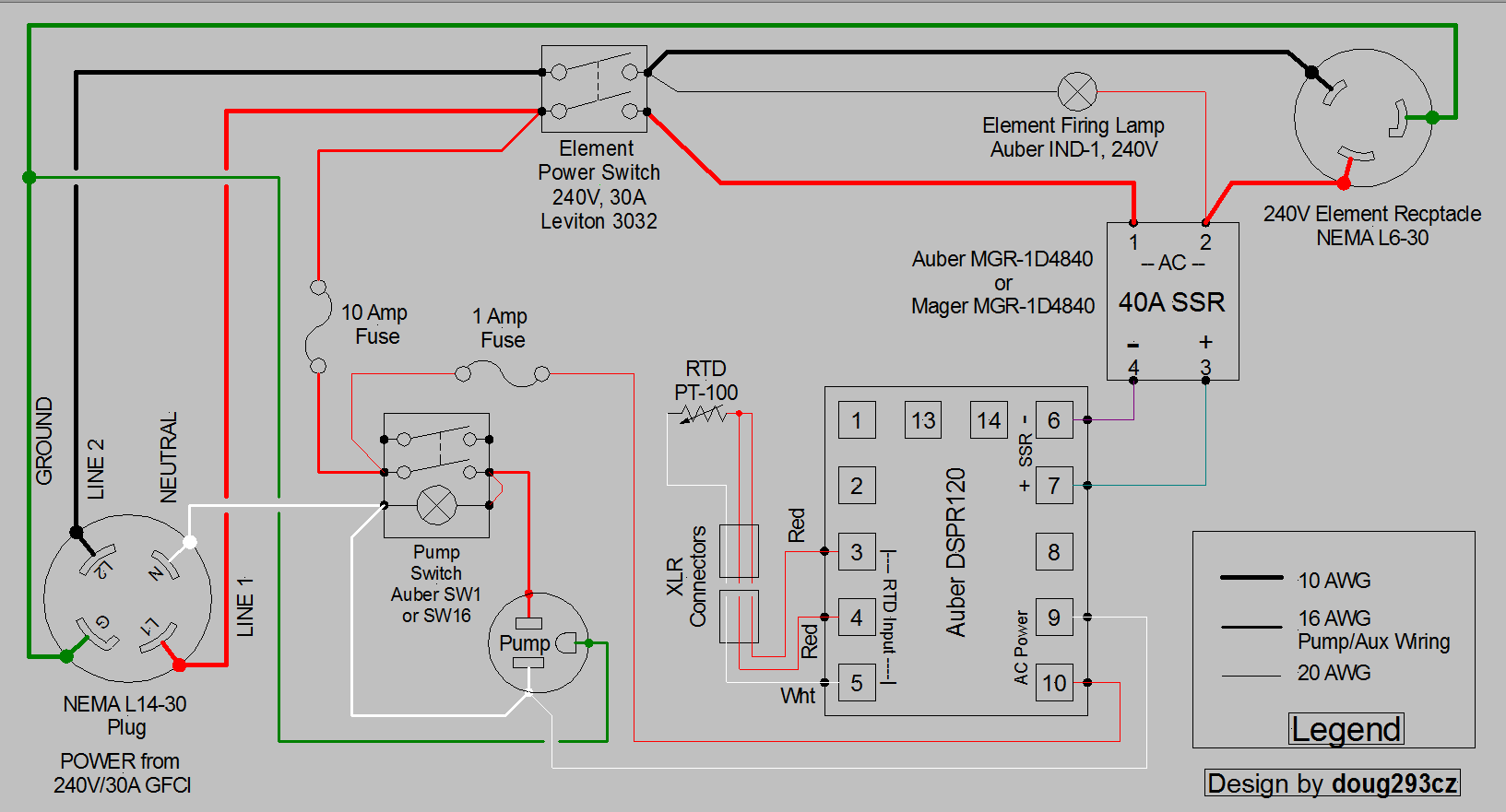

These are awesome. I'm planning a move to a recirculating eBIAB and the top design looks like what I'm wanting. I have a few questions:

The items needing cutouts on the front of the panel would be:

The DSPR310

The two SW16's

The IND-1 firing lamp

Also, the SW8 key switch

Then the bottom (or back if a tabletop approach) would need cutouts for:

XLR Temp connectors (why two?)

Not two connectors, but rather one connector pair (plug and receptacle)

NEMA L6-30 Receptacle

There is an option here. You can put the receptacle in the enclosure, or if you have an element with an integral L6-30 plug, you can use a strain relief at the panel and an L6-30 receptacle on the element end of the cord.

standard 120v receptacle for the pump

Power in receptacle or strain relief if hard wired

Power input must always be a plug (male - receptacles are always female), otherwise the power cord would have exposed plug blades at the panel end, which is a HUGE safety hazard, and a code no-no. If you use a strain relief at the panel, then the other end of the cord must have a plug for a wall socket. Code won't let you hard wire the panel to your electrical service (cause your home built panel, by definition, is not code compliant.)

Am I missing anything? Any advice for layout (both internal and external)?

Layout depends to a great extent on the actual enclosure you choose. Too, many possible options for me to make specific recommendations on interior layout. I do suggest you mock everything up for fit before you start cutting any holes.

For SSR/heatsink mounting, I recommend mounting the heatsink on the side of the enclosure (based on the orientation the enclosure will have during use) with the heatsink fins oriented to allow maximum vertical airflow. The hole in the enclosure should be slightly larger than the base of the SSR, so that the SSR can mount directly to the heatsink (with a little thermal grease in between), and the heatsink attached to the enclosure wall.

The SW16's come in two NO or 1 NO and 1 NC configurations. Looking at the diagram, I'm assuming the 2 NO configuration?

You can use either the 2-NO or 1-NC/1-NO, since you are only using one of the switch blocks (NO) in this design. However, by using the 1-NO/1-NC version, you have the option to add a "safe start" power interlock later, if you so choose. 2-NO is best for the SW8.

The part numbers for the 40A SSR don't show up on Auber's site.

Is this one acceptable?

That is the MGR-DS4840, Auber just calls it something else on their catalog page (note that they use of picture of the 25A MGR-DS4825 on that page - sloppy editing.)

Any other advice? I built a guitar amp about 10 years ago, but for that I had a wiring diagram and a drawing of the layout (where to route the wires, etc.). This shows the connections, but is pretty much a blank slate for how to lay it out.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)