guitarguy6

Well-Known Member

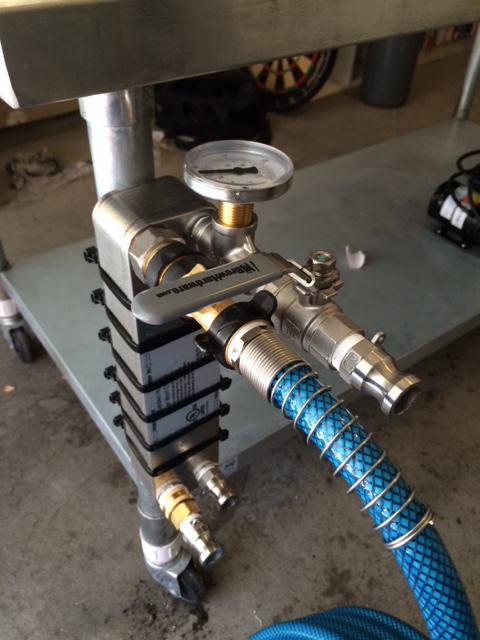

Hey guys, I found a used plate chiller for sale cheap and am wondering how it should be set up in order to not get trub in the carboy. From my brief research it seems like the wort is taken from the kettle, put through the plate chiller and dumped into the carboy. Wouldn't this get all your trub into the carboy? The other setup I came across was going from the kettle to the plate chiller and then back to the kettle. This makes more sense to me as once you hit your fermentation temp you could whirlpool and then syphon into your carboy. I'm assuming this is only possible with a pump. What pump would you recommend? Anything else I'm missing? This is the plate chiller I'll be purchasing. http://fermentap.com/products/wort-chiller-shirron-plate.html

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)