glutarded-chris

Well-Known Member

I took the plunge and purchased a Grainfather G30 Connect 220V so that I can do rising temperature mashes. I wired up my 220VAC plug last weekend while it was being shipped.

I am hoping there are still some gluten free brewers viewing this forum that have experience with the Grainfather!

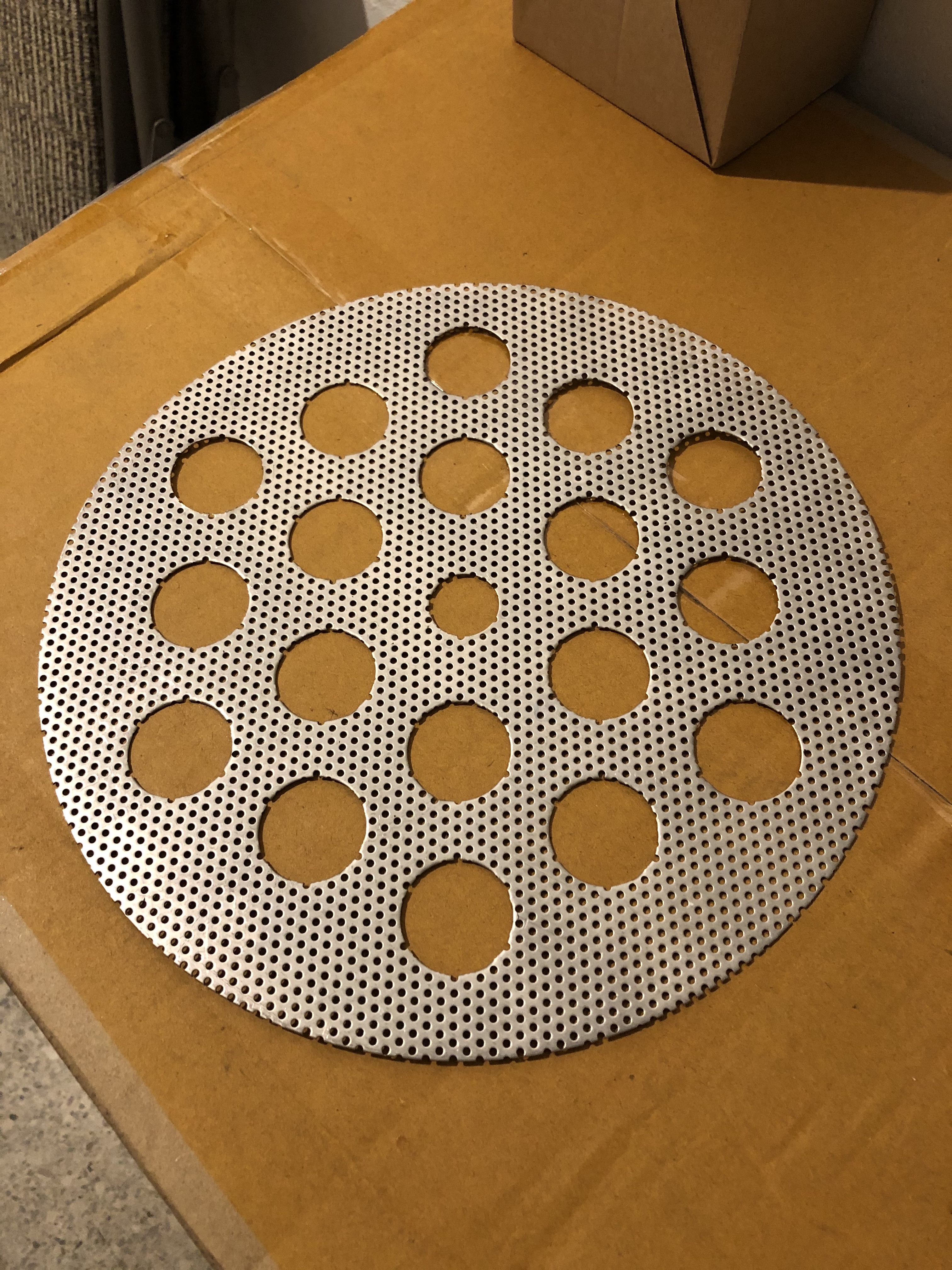

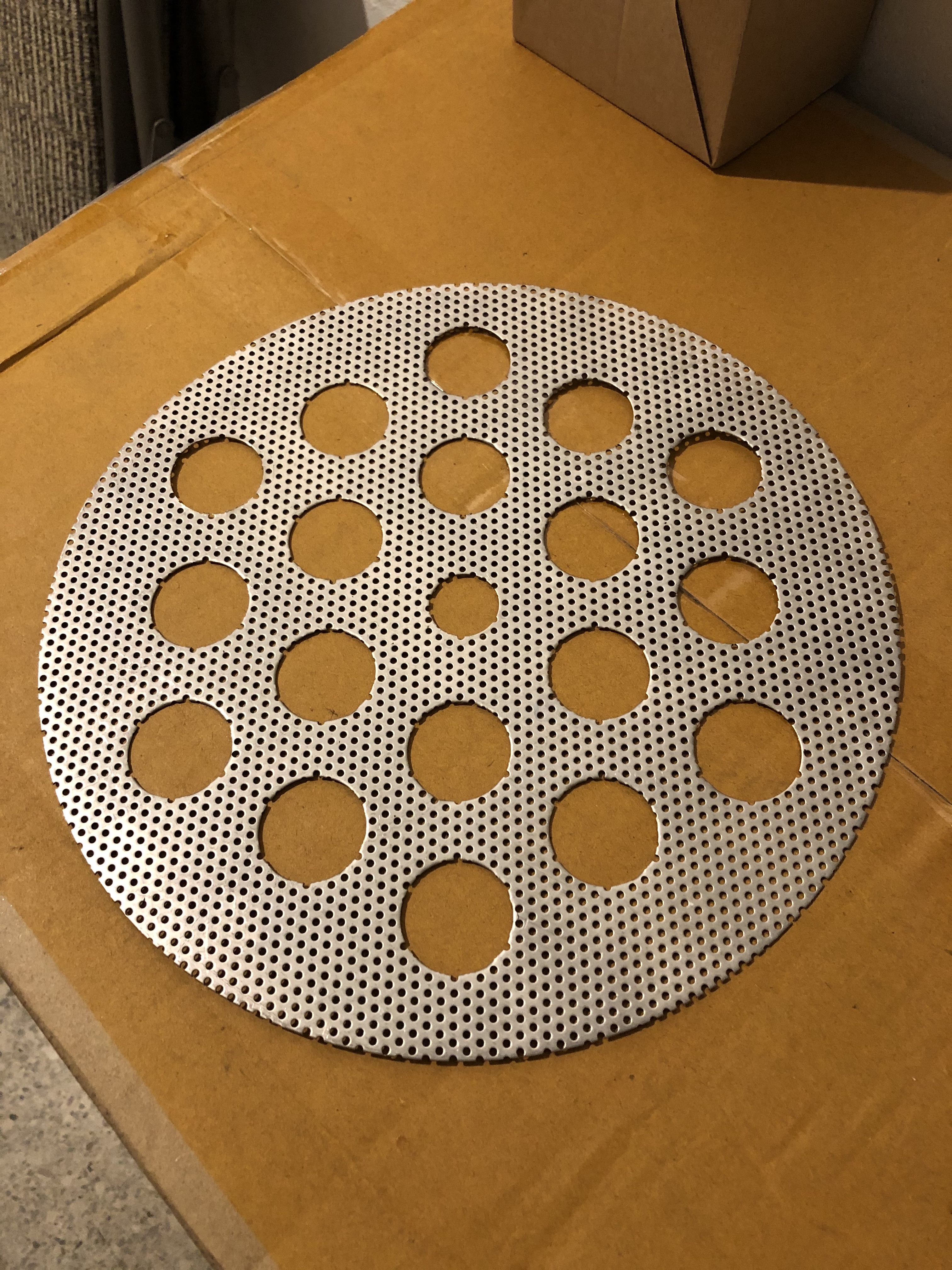

I watched the videos on the glutenfreehombrewing.com site and purchased their 1000 micron screen. I did not like the solution of trying to wrap the silicone seal around the edge of the false bottom and the 1000 micron screen to stabilize the screen. My solution was to purchase a second false bottom with the Grainfather and sandwich the flimsy mesh screen between the two false bottoms. Only one would have the silicone seal. I punched some holes in the second false bottom in an attempt to reduce the flow restriction while still maintaining some rigidity. Hoping this works.

I will clean and test the system this weekend, but not sure if the first real brew day will be this weekend.

Here is the second false bottom after punching the holes:

I am hoping there are still some gluten free brewers viewing this forum that have experience with the Grainfather!

I watched the videos on the glutenfreehombrewing.com site and purchased their 1000 micron screen. I did not like the solution of trying to wrap the silicone seal around the edge of the false bottom and the 1000 micron screen to stabilize the screen. My solution was to purchase a second false bottom with the Grainfather and sandwich the flimsy mesh screen between the two false bottoms. Only one would have the silicone seal. I punched some holes in the second false bottom in an attempt to reduce the flow restriction while still maintaining some rigidity. Hoping this works.

I will clean and test the system this weekend, but not sure if the first real brew day will be this weekend.

Here is the second false bottom after punching the holes:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)