vinylrooster

Well-Known Member

To make a long story short, I got a stuck sparge when doing a heavy grain bill (really it was one out of a dozen batches that was 25#, but it bothered me nonetheless). I attributed this to grain sneaking under my false bottom around the edges because it didn't sit flush against the inside edge of the cooler when there is too much weight. So I decided to make a diy cheap gasket for the fake bottom (more beer domed 12").

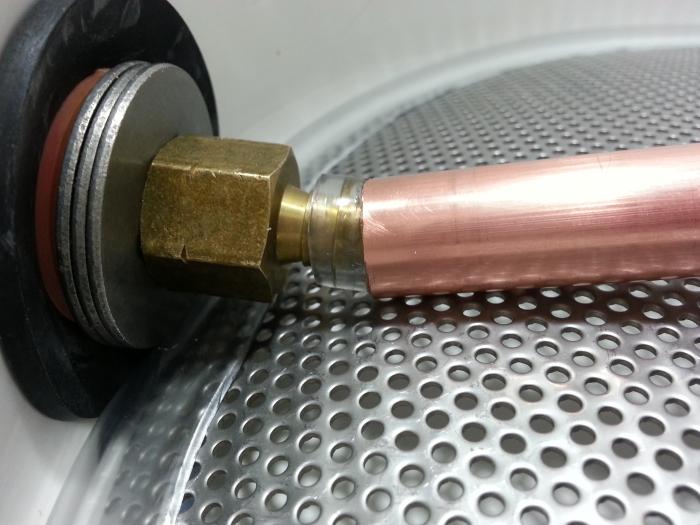

I bought some 3/8" inch high temperature clear tubing (6 feet to be safe) from northern brewer and cut it down the middle, being careful to cut the "inside" of the coil [picture 1]. Then I wrapped the tubing around the outer edge of the false bottom [picture 2/3]. I also added a "handle" made of copper threaded through the false bottom holes then tied underneath. Then I tested the fit and it seems pretty perfect [picture 4]. Picture 5 shows how tight the gasket is between the wall of the cooler and the false bottom.

Let me hear your thoughts. I'll update after I test her out.

-Rooster

I bought some 3/8" inch high temperature clear tubing (6 feet to be safe) from northern brewer and cut it down the middle, being careful to cut the "inside" of the coil [picture 1]. Then I wrapped the tubing around the outer edge of the false bottom [picture 2/3]. I also added a "handle" made of copper threaded through the false bottom holes then tied underneath. Then I tested the fit and it seems pretty perfect [picture 4]. Picture 5 shows how tight the gasket is between the wall of the cooler and the false bottom.

Let me hear your thoughts. I'll update after I test her out.

-Rooster

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)