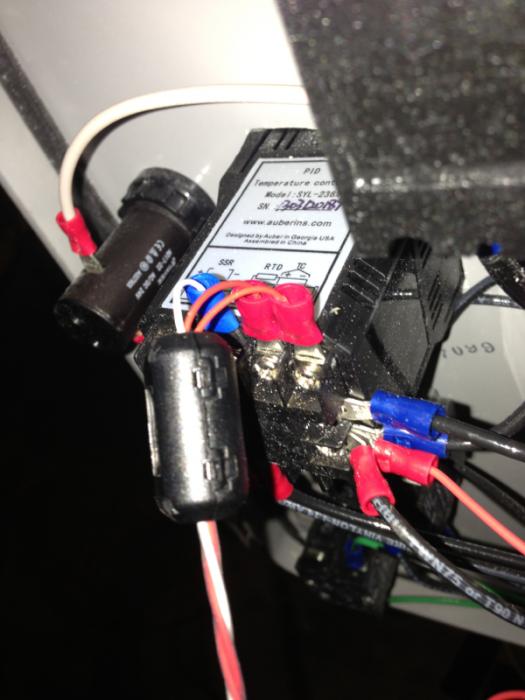

This is the RTD I am using (the deluxe model)

http://www.auberins.com/index.php?main_page=product_info&cPath=20_15&products_id=267

The part external to the control panel is shielded but the inside section is not. Should/Can I make a change here that would help? I will pick up the sleeve tomorrow and try it out. I am a little confuse of where to put the sleeve/sleeves. Close to the panel? Exterior or Interior. I guess I am thinking it should be clamped as close to the PID as possible. Is this correct?

http://www.auberins.com/index.php?main_page=product_info&cPath=20_15&products_id=267

The part external to the control panel is shielded but the inside section is not. Should/Can I make a change here that would help? I will pick up the sleeve tomorrow and try it out. I am a little confuse of where to put the sleeve/sleeves. Close to the panel? Exterior or Interior. I guess I am thinking it should be clamped as close to the PID as possible. Is this correct?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)