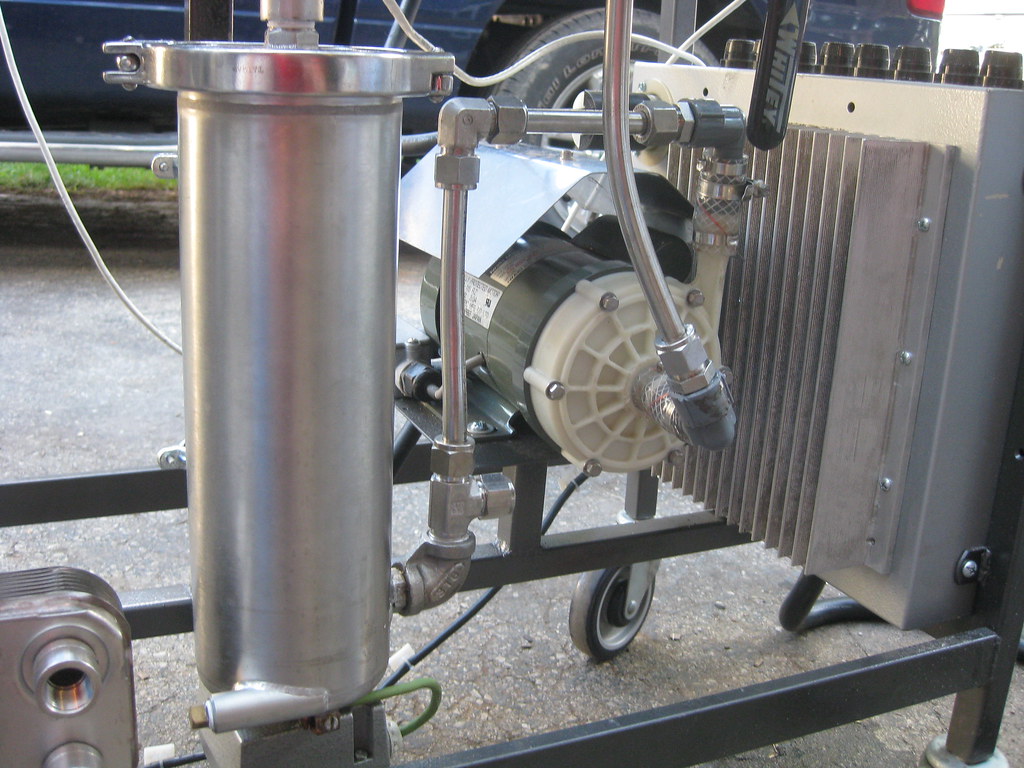

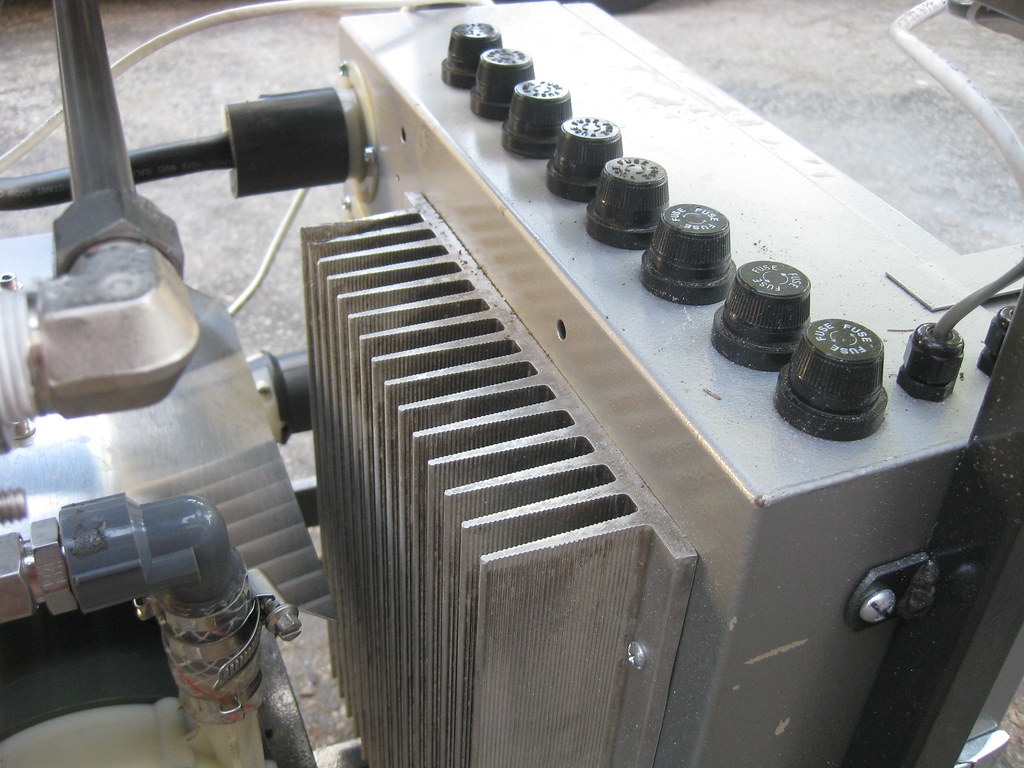

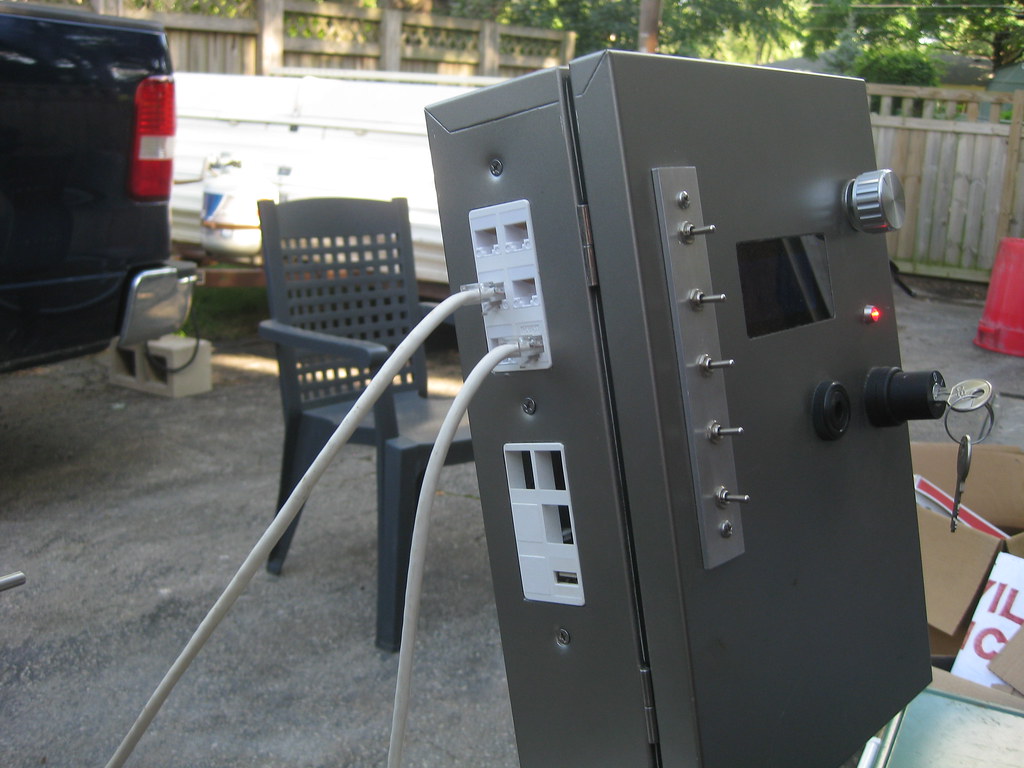

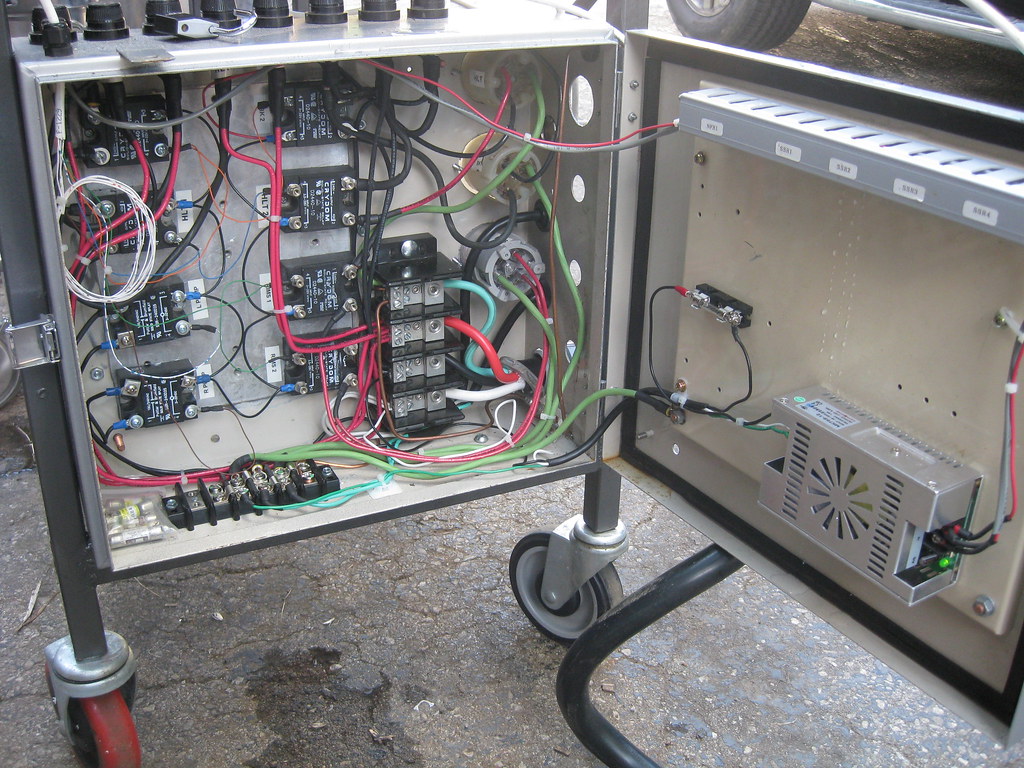

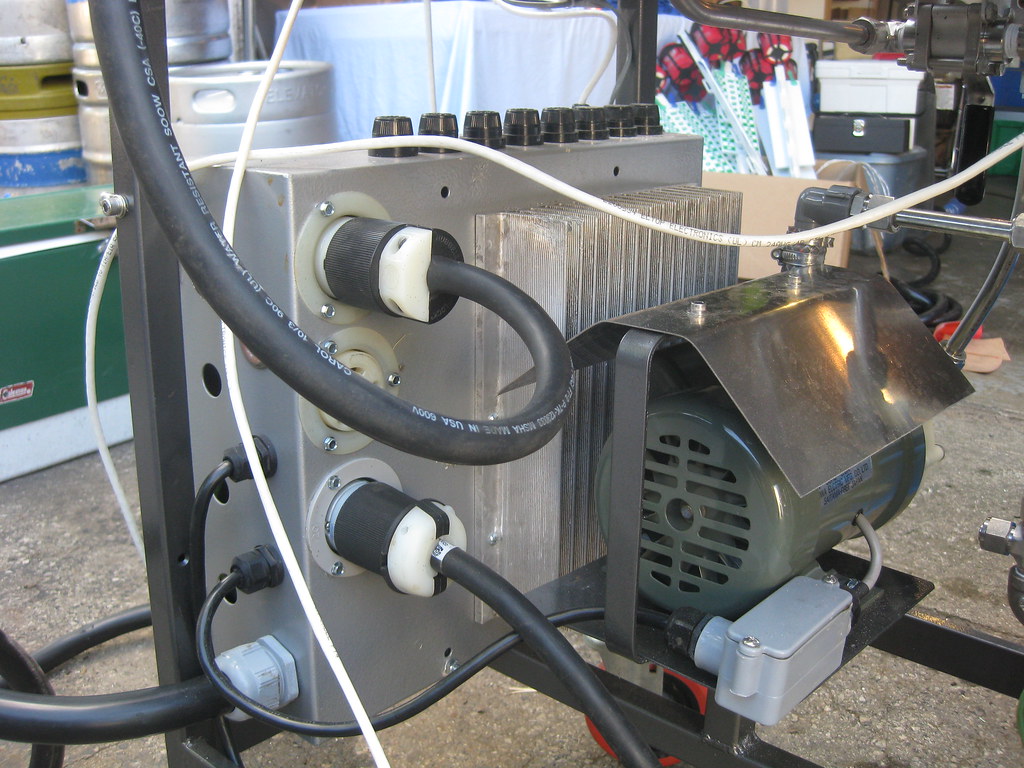

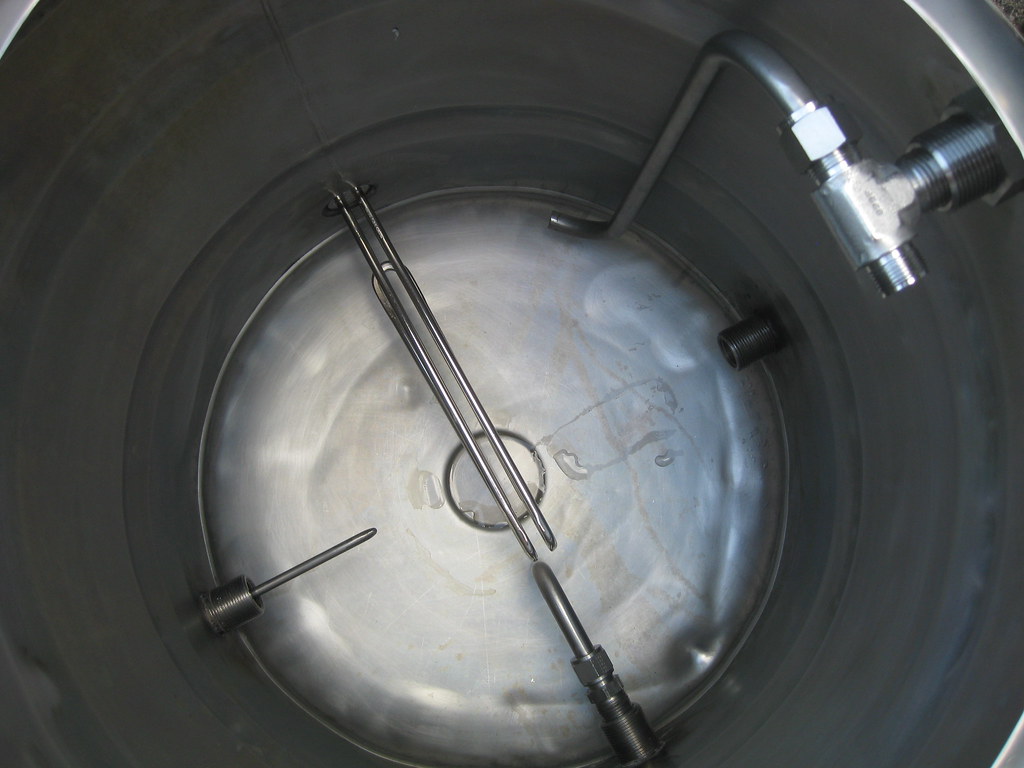

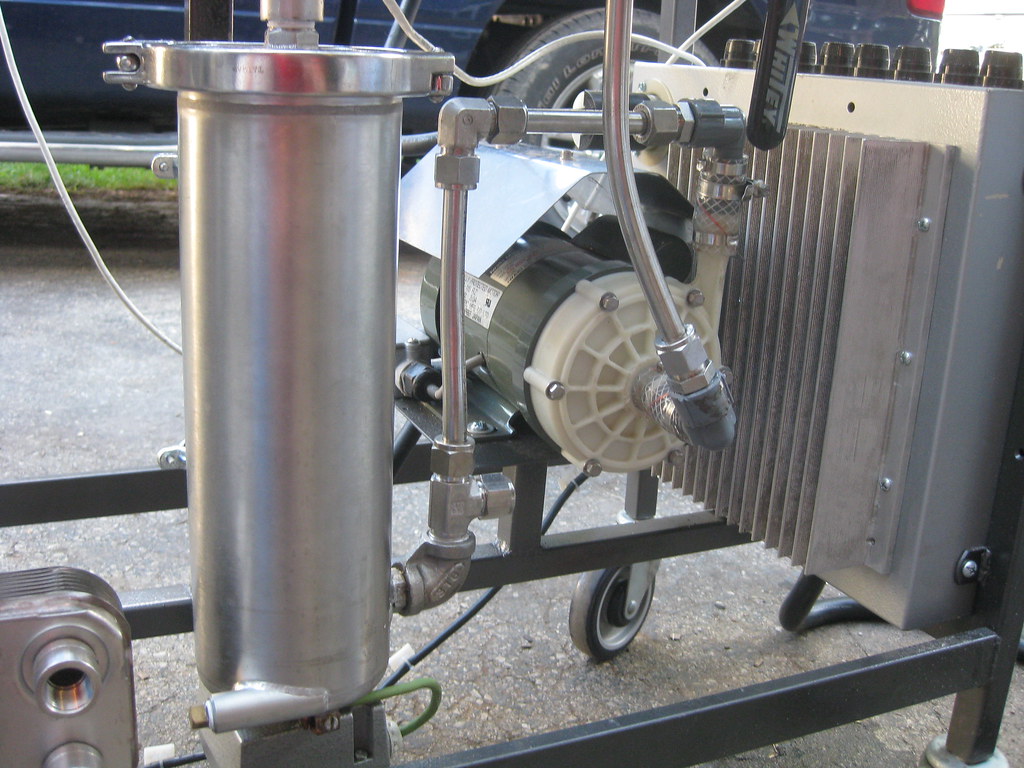

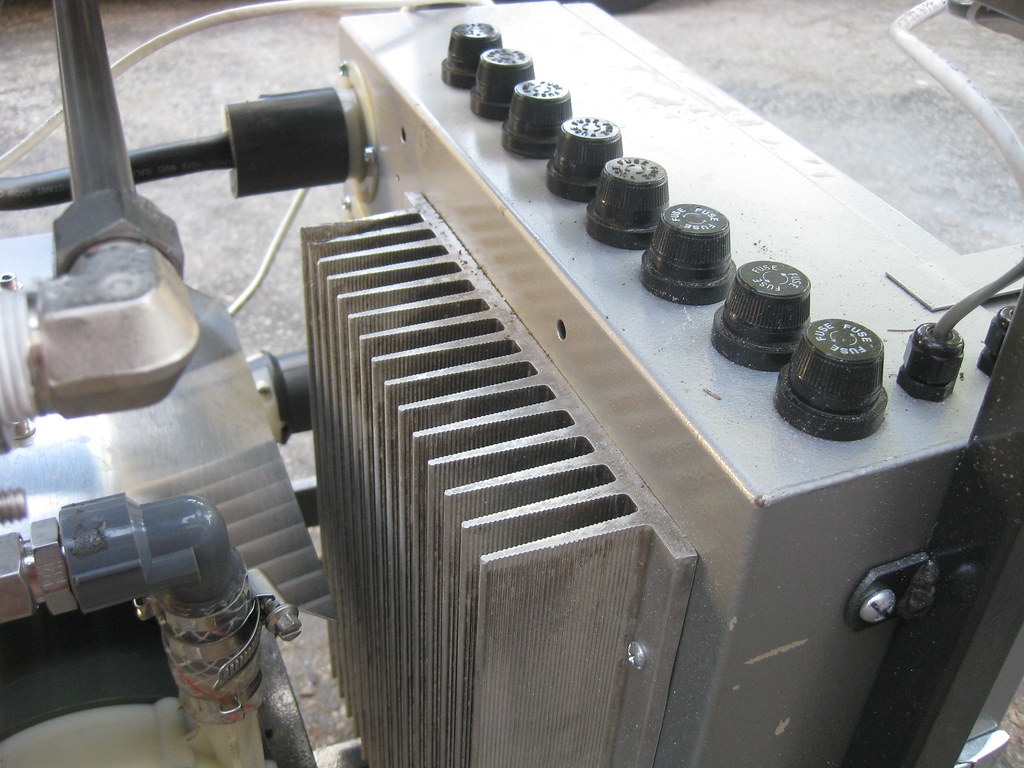

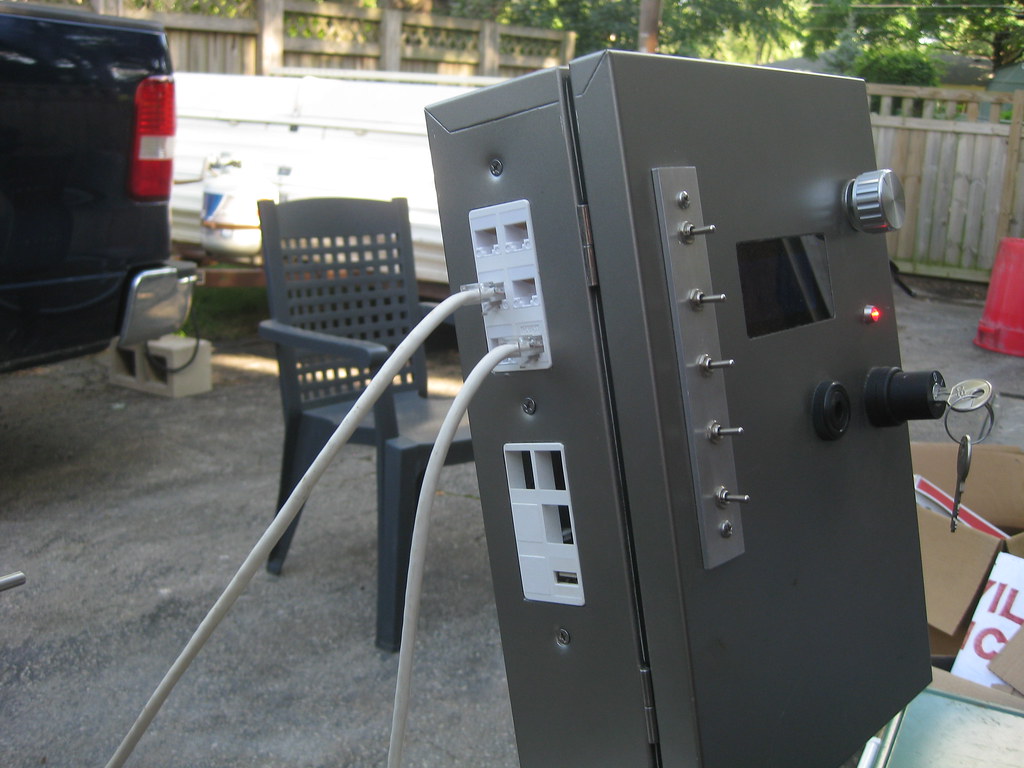

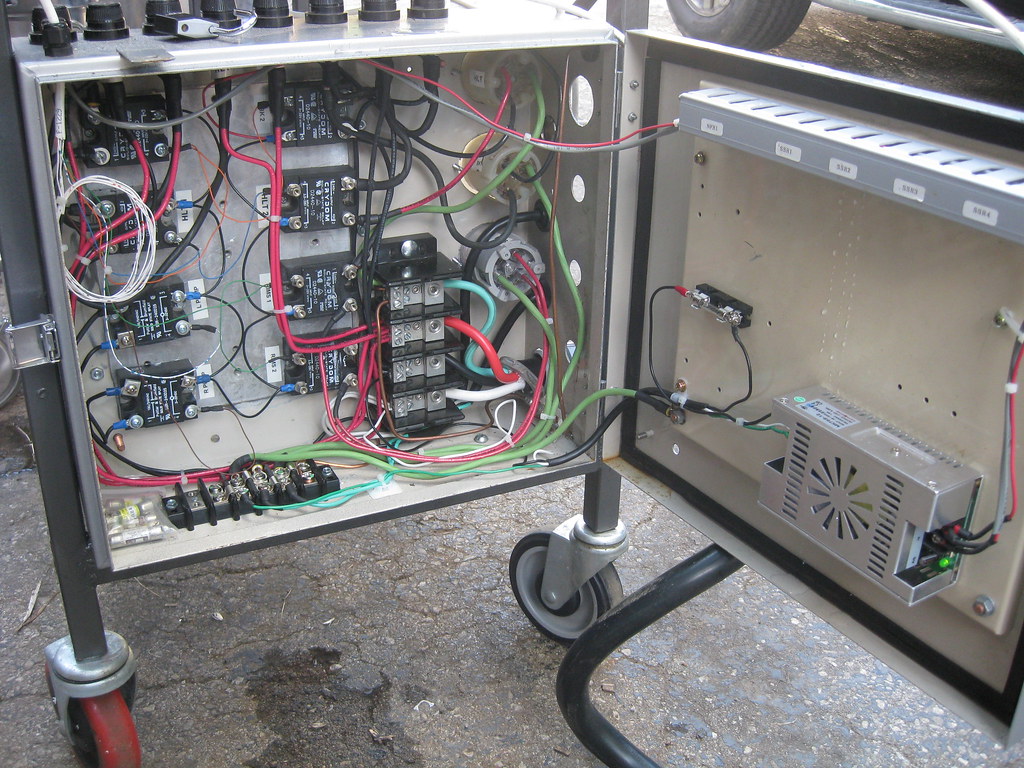

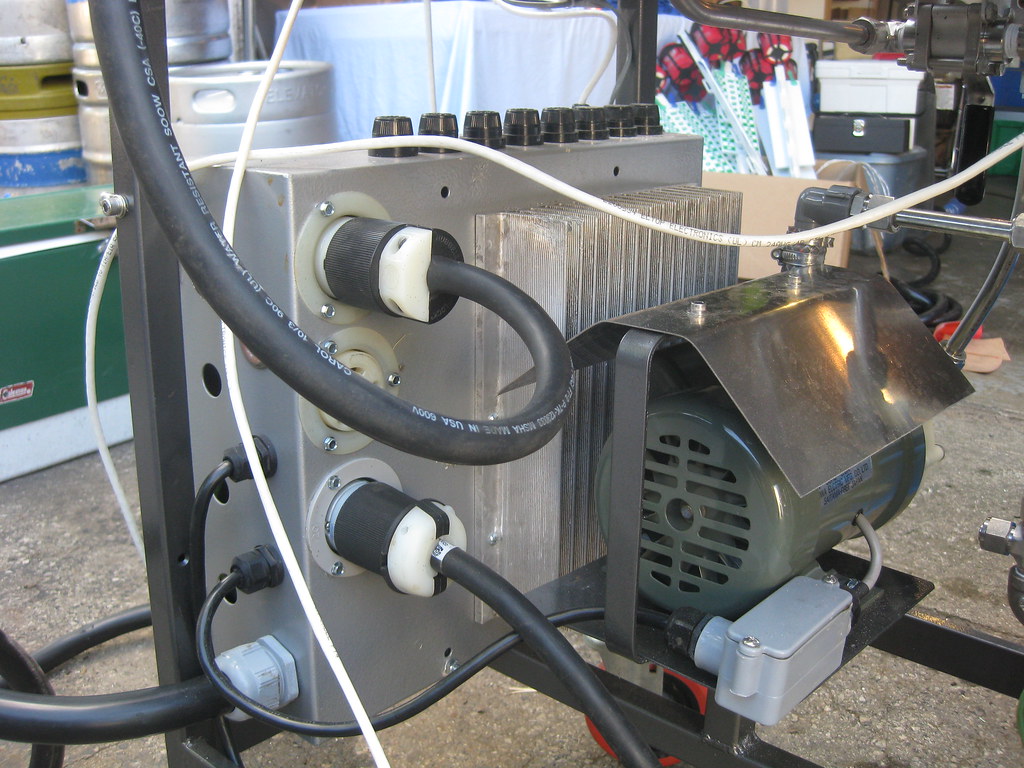

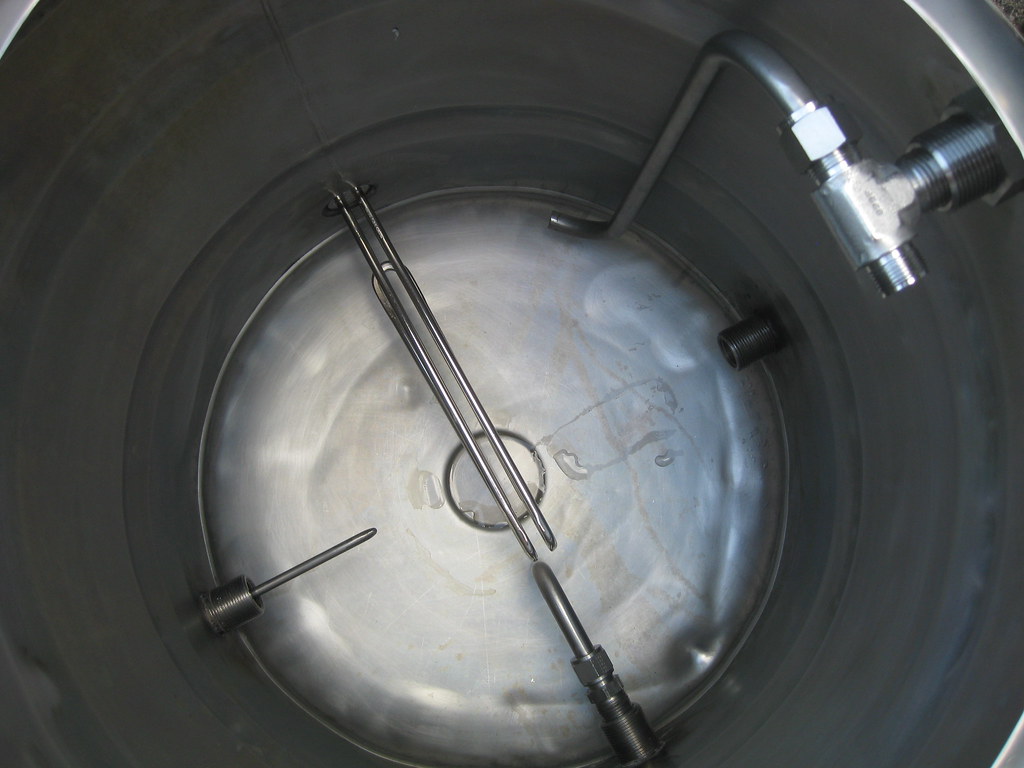

Well it's 99% done, just a few things to button up. I plan to send her on the maiden voyage next saturday. It's powered by 50A GFCI, SSRs on all hot legs, two 4500W elements (one in HLT and one in BK), RIMS has a 3500W element. All running on 220v. All 1/2" stainless plumbing (except the connections to the pump heads where I transitioned from hose barb to SS). Two Iwaki MD-70RLZ (~ 1/3 hp) pumps; I've measured flow rate from one vessel to the next (through the RIMS) at 7.5 gpm at full throttle. It has an Alfa Laval plate chiller (816 square inches) located in the lower left and the small vessel on the ground in front is a hopback that I haven't quite finished. And of course, its BrewTroller controlled. I did a quick test with 5.5 gallons; using the HLT element and the RIMS and was able to raise the water temp 56F in 10 minutes. You'll notice that for the HLT and MT I used the 2" sanke connector on the keg as my drain. A 2" tri-clover fits perfectly; and I don't have any dead space and don't have to worry about losing a siphon.

[/URL] Uploaded with ImageShack.us[/IMG]

[/URL] Uploaded with ImageShack.us[/IMG]

More pictures

More pictures

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)