Here are some photos...

#1 - This is where all the connections come in. The manifold has four inputs at the top and one at the bottom. The one at the bottom is immediately connected to the faucet. One of the first revisions I'll make later this year is adding in a digital flow meter before the faucet so I can measure how much is being poured.

#2 - A photo to give you some idea of how close the check valves are to the manifold.

#3 - A photo of when I was putting everything together in the box. I don't currently have a back cover to the box, as I plan to make a lot of adjustments over the next few months. I have two work boxes installed inside the box. The top one with the weatherproof cover houses the Arduino board and the Raspberry Pi computer. The second box is just to help keep the mess of wires somewhat organized. I'm going to need a bigger box as all the stuff doesn't fit into that second box.

You can see the four solenoid valves at the bottom. Long-term, I'd like to separate the electronics from the dispensing system. I'll probably make a box that doesn't attach to the keezer lid to hold that stuff and then another box that does attach to the lid to hold the manifold and tap.

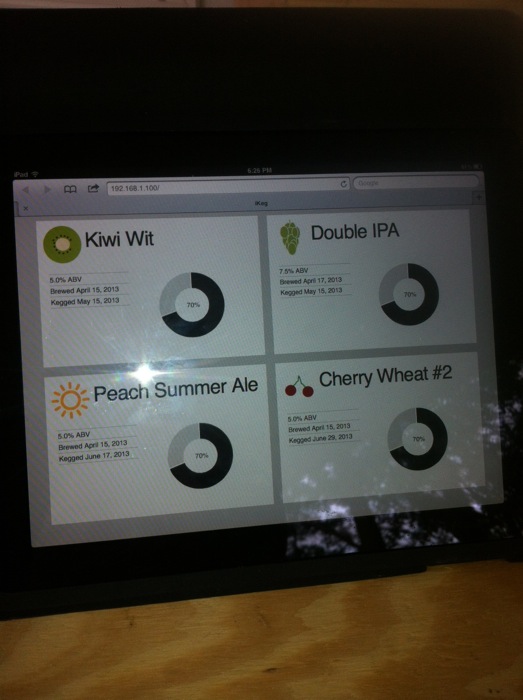

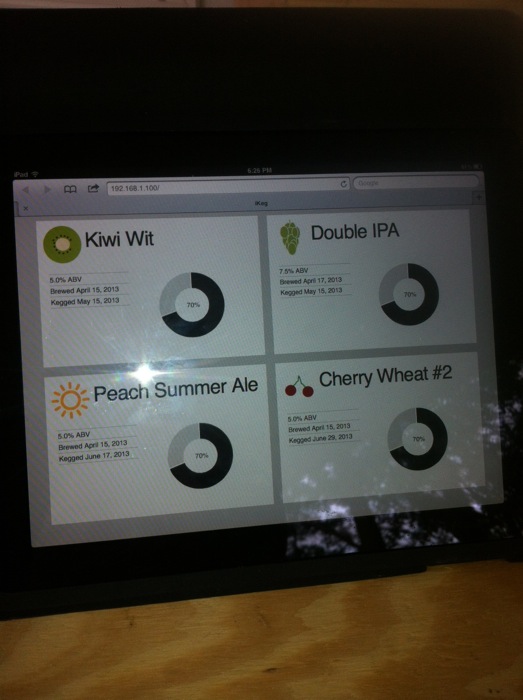

#4 - Photo of the iPad interface. I made this part of the interface very simple. You see a small icon with a headline of each of the beers. There is also some brief info on each of the hombrews. I'll probably expand this out to more detail to help educate our guests who might not know what a beer is from the title. You can touch anywhere on each of the four boxes to "arm" the system.

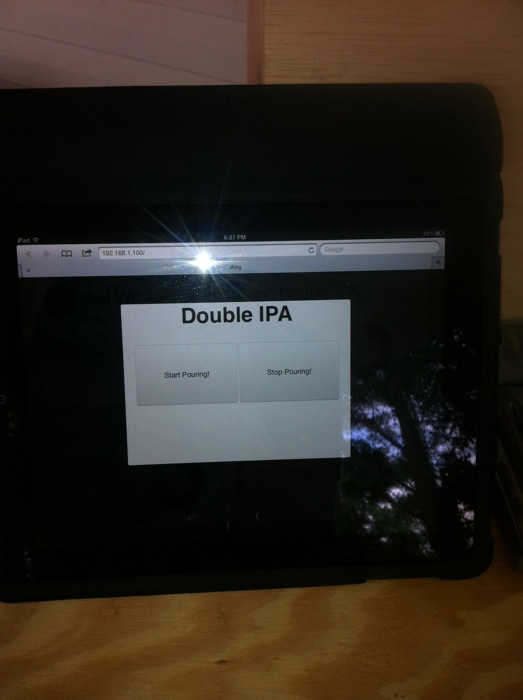

#5 - Photo of the iPad interface once a beer is "armed". It brings up a modal window with buttons to start and stop pouring. My initial plan was to have a physical toggle switch on the box that you would have to click on and off, but I ran into too many unexpected problems that needed fixed and that fell off my priorities list. Some of the people who got to use the system this week thought it was cool to control the pouring with the iPad, but I'd prefer to rig up a tap handle that's actually a toggle switch so you only use the iPad to select a beer to pour and then open and close the tap handle to actually pour.

#6 - Photo of system in operation. You can see the hillbilly nature of this current setup with the router sitting on top of the keezer

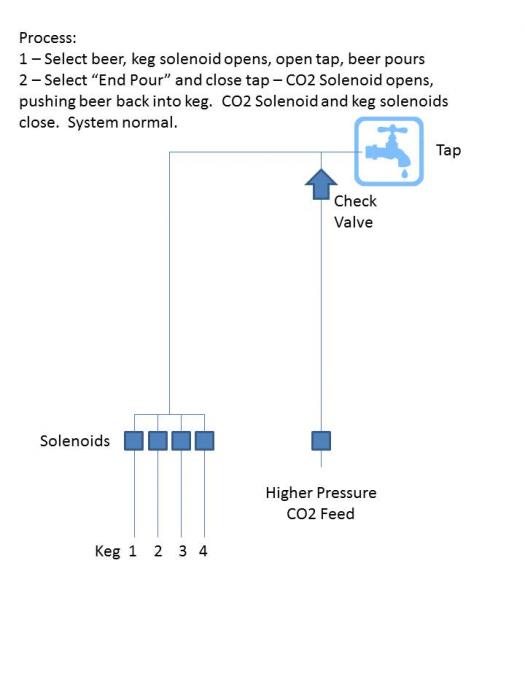

Because I didn't have time to figure out how to make the iPad talk directly to the Arduino (programable microcontroller that controls the solenoid valves), I came up with this networked approach. The way this works is that the Arudino attaches to a Raspberry Pi (a tiny, but fully functional linux computer). The Raspberry Pi runs a web server and sends commands to the Arduino over USB. The Pi attaches to the router via an ethernet cable. The iPad then just uses its Safari web browser to load the web page from the Raspberry Pi web server. The web page uses Javascript/AJAX to make server calls to the Raspberry Pi telling it what beer to select and then the Raspberry Pi tells the Arduino which valve to turn on.

The drawback to this system is that I need to use a router to do this, which is cumbersome. The benefit is that I can actually use any smart device with wi-fi to control the keg system, so I could use my iPhone or iPad and others can use their Galaxies, Kindle Fire's, etc.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)