No, this isn't a fluid dynamics thing, it's about potentially damaging a kettle drain by bumping into an excessively long rigid drain path...

Cheers!

Cheers!

I see.No, this isn't a fluid dynamics thing, it's about potentially damaging a kettle drain by bumping into an excessively long rigid drain path...

Cheers!

BSP and NPT are, if you look at their specs, perfectly identical only in the 1/2" size. Every other size is totally incompatible.I'm under the impression that BSP and NPT are more-or-less compatible at the 1/2" size, especially with the use of tape.

Although I don't know what a long lever moment is.

I believe there's still a slight difference in thread diameter at the 1/2" size.BSP and NPT are, if you look at their specs, perfectly identical only in the 1/2" size. Every other size is totally incompatible.

I second this.. I have many plastic bsp 1/2" threaded things paired up with NPT counterparts including all my tan dc pumps I use at home.If there is it's so minuscule that you can hand-tighten them with no effort whatsoever.

Thread size and pitch are 100% identical and that's what really matters as even a minor difference in pitch would cause the parts to seize after less than a full turn.

why cant you just make some marks on the inside of the MLT for gallon and half gallon levels?

Sorry, brain fart. Here it is:

https://www.aliexpress.com/item/329...chweb0_0,searchweb201602_2,searchweb201603_53

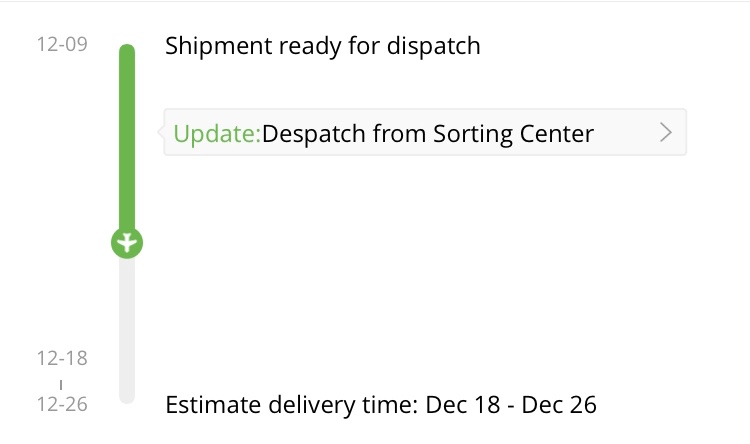

The stuff I have ordered from China (not a lot) always showed up way earlier than the estimate. I think they tend to use worst case shipping times to avoid over promising and getting complaints.This is my first time ordering through AliExpress. Is shipping as slow as it appears? Currently it’s showing it’s due within “55 days, 8 hours, 35 minutes, 22 seconds”. I guess maybe they make up for in speed with precision?

I've never underlet my mash . I run my water into the MT (Igloo cooler) to preheat it, I run a few degrees over so the temperature of the tun compensates and within 10 minutes of preheating I either add hot water to raise the temperature or lift the lid to cool to get to my dough-in pre-mash temp. I add the mash to the water and stir as I do. NOT add water to the mash so as not to have dough balls. Then I either single mash infuse or step mash depending on my recipe/style. I also double or triple batch sparge to pre-boil volume...so your idea that its not always that simple is out the window. It IS actually that simple. No need to complicate things as some people like to do . I read about the use of pumps(I've tried it, went back to my manual method long used- its called gravity and adjust flow by opening or closing the hand valve a certain degree) , flow meters, computer control panels, all the electro-gizmos and techno-gadjets used to do such a simple process. My Lord, just graduate your vessels ,use common sense and simple measuring tools, stand there and brew your beer. Its not like we're sending crude oil into the cat cracker to make gasoline here.That won't work if you're underletting. Not sure if the OP is doing that, just pointing out that it's not always that simple.

I've never underlet my mash . I run my water into the MT (Igloo cooler) to preheat it, I run a few degrees over so the temperature of the tun compensates and within 10 minutes of preheating I either add hot water to raise the temperature or lift the lid to cool to get to my dough-in pre-mash temp. I add the mash to the water and stir as I do. NOT add water to the mash so as not to have dough balls. Then I either single mash infuse or step mash depending on my recipe/style. I also double or triple batch sparge to pre-boil volume...so your idea that its not always that simple is out the window. It IS actually that simple. No need to complicate things as some people like to do . I read about the use of pumps(I've tried it, went back to my manual method long used- its called gravity and adjust flow by opening or closing the hand valve a certain degree) , flow meters, computer control panels, all the electro-gizmos and techno-gadjets used to do such a simple process. My Lord, just graduate your vessels ,use common sense and simple measuring tools, stand there and brew your beer. Its not like we're sending crude oil into the cat cracker to make gasoline here.

I'm Sorry, I've addressed this before and its only my opinion. I just dont understand the complexity some brewers go to . I just see most of it as unnecessary.

[...] I just dont understand the complexity some brewers go to . I just see most of it as unnecessary.

same reason as you. its called conversation and communication on a particular subject.Why are you here?

BSPT (British Standard Pipe Thread) is similar to NPT except there are important differences. The angle across the flanks of threads (if you sliced the fitting in half long-ways and measured the angle from root to crest to root) is 55 degrees instead of 60 degrees as it is for NPT. Another important difference is that for many BSPT pipe sizes the thread pitch is different than NPT. Thus an NPT male will sometimes fit into a BSPT fitting or vice versa but they will not seal. This is a popular fitting in China and Japan but is very rarely used in North America unless the equipment to which it is attached was imported.

same reason as you. its called conversation and communication on a particular subject.

I just see all these people going to the automated extreme , then when the time comes find they have to figure out what went wrong.

Whats that comment supposed to mean.Yeah, my wife doesn’t get me either

Whats that comment supposed to mean.

well, my wife and I "get" each other very well. She enjoys my hobbies almost as much as I do . I enjoy tinkering too, I call it Putzing. I'm resto-modding a 1951 chevy 3100 1/2 ton pickup at the moment . My wife is behind me all the way. Shes even looking for parts for it. She found the bumper for it ,its a 1950 Cadillac bumper, we just got it from the chrome shop the other day .First time we've actually seen it since she found it on ebay way out in California, its beautiful.It just means that we all have our own motives for brewing, and get joy out of different aspects of the hobby. Truth be told, I enjoy the “tinkering” evolved as much as the brewing itself. My wife is very much task oriented, and it drives her mad to see me do something a different way just for the sake of seeing if I could.

I know,youre exactly right and I get that . I just see it as trying to reinvent the wheel or a better mousetrap. Im just an old school "if it aint broke dont fix it" kind of guy.@Soulshine2

I'm not just tinkering; I'm lazer focused on the final product and actually don't care about the brewing process all the much aside from making it tolerable. However, beer is the sum of its parts so every part of the process require attention.

I have particular standards for what I enjoy drinking. Part of the optimization is step mashing and wort clarification. RIMS provides a way to do that. A flow meter helps optimize the digital control of wort heating for the RIMS, to prevent excessive thermal stress/scorching.

There's nothing right or wrong about my brewing philosophy or yours. It's just a hobby, no reason to rant when someone has different goals than you do.

I've never ordered from AliExpress before. Should I open a dispute before the "Purchase Protection" ends since I haven't received the item yet? That's what the email said to do. Seems like an annoyance; they have the tracking number & they know I haven't gotten it yet.

I would do it... I had to once, aliexpress refunded me and the beer taps arrived 2 days later.. I didnt have to but I went ahead and sent payment again because the product was shipped as promised but just took much longer than expected.I've never ordered from AliExpress before. Should I open a dispute before the "Purchase Protection" ends since I haven't received the item yet? That's what the email said to do. Seems like an annoyance; they have the tracking number & they know I haven't gotten it yet.