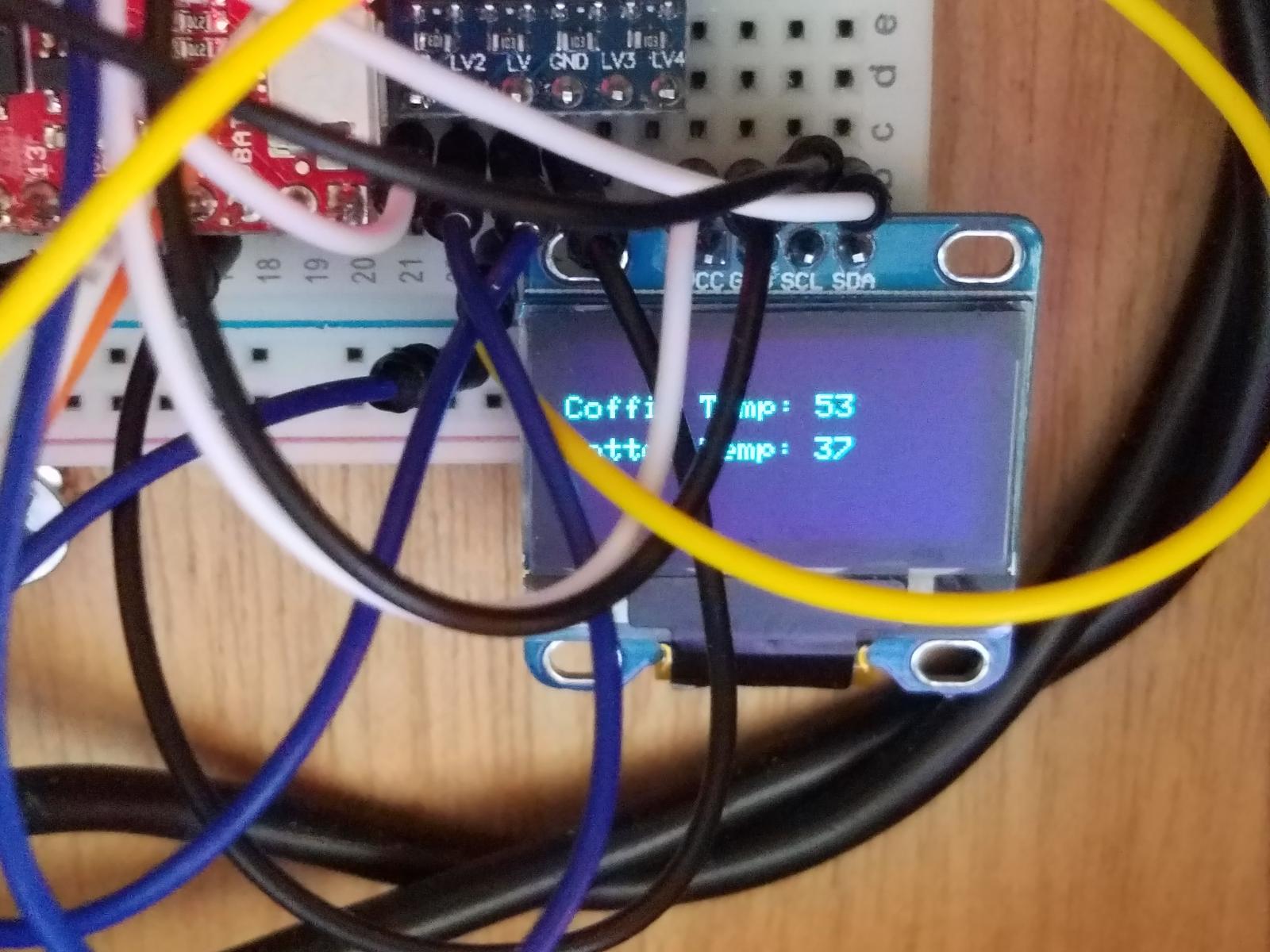

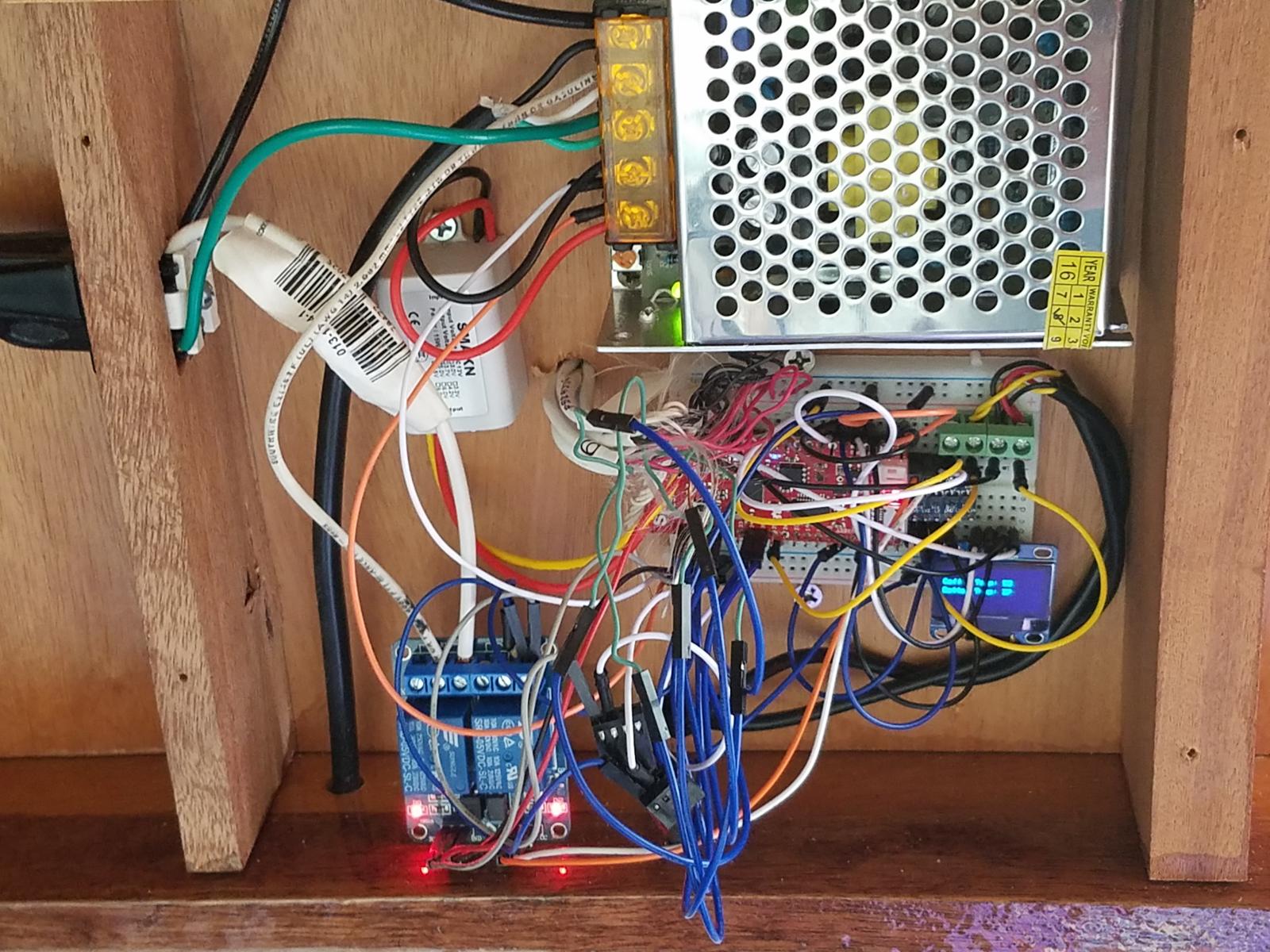

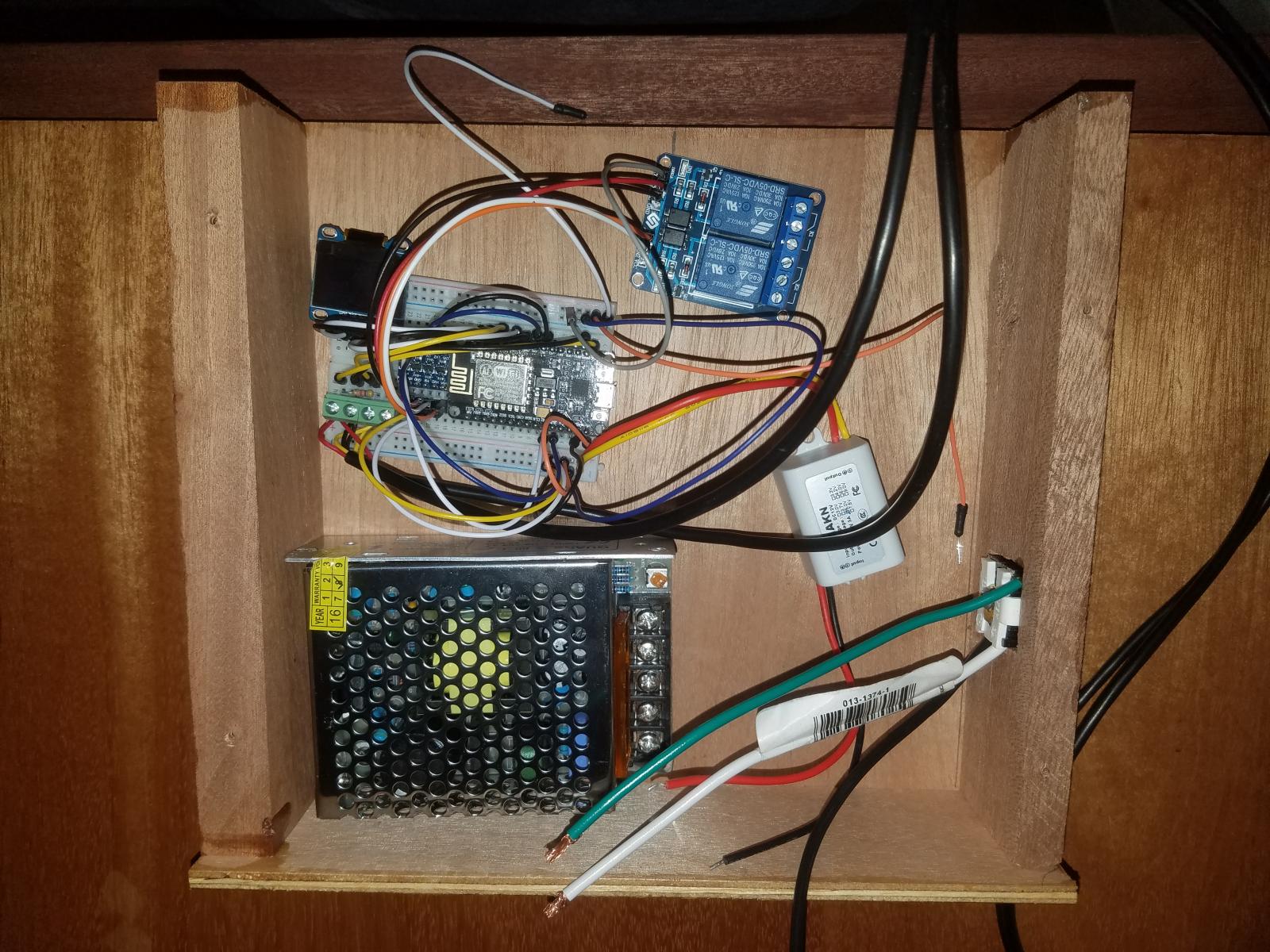

I have been lurking on the forums for over a year. Some threads on here gave me a "need" to build me a keezer with an Irish coffin. Things left at this point is to epoxy the top, install electronics, and debug.

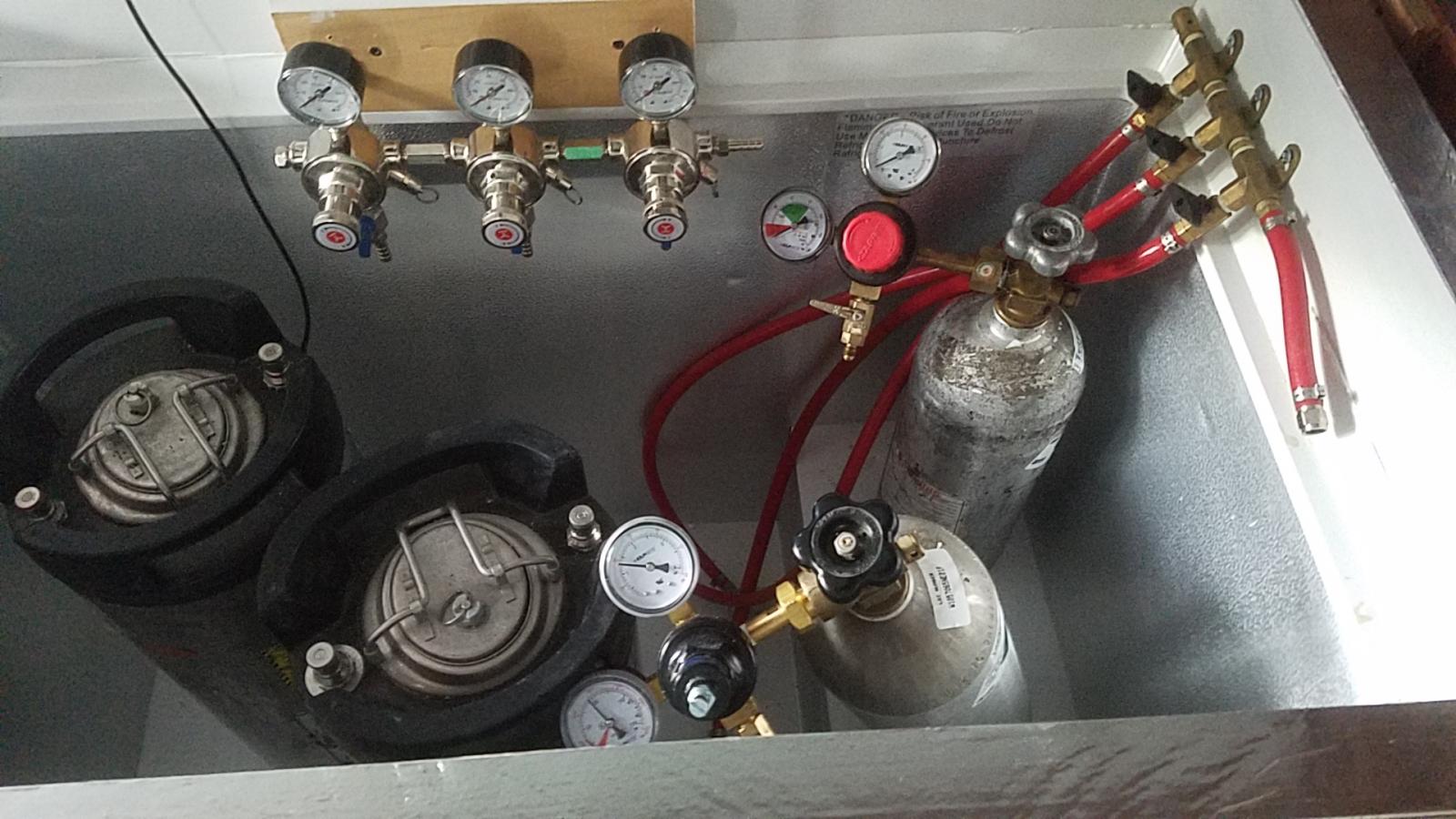

It is an insignia 10 cu.ft. that can fit 6 kegs with CO2 and Beer gas. Ill provide details in a bit.

It is an insignia 10 cu.ft. that can fit 6 kegs with CO2 and Beer gas. Ill provide details in a bit.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)