Dabba

Well-Known Member

- Joined

- May 6, 2017

- Messages

- 120

- Reaction score

- 7

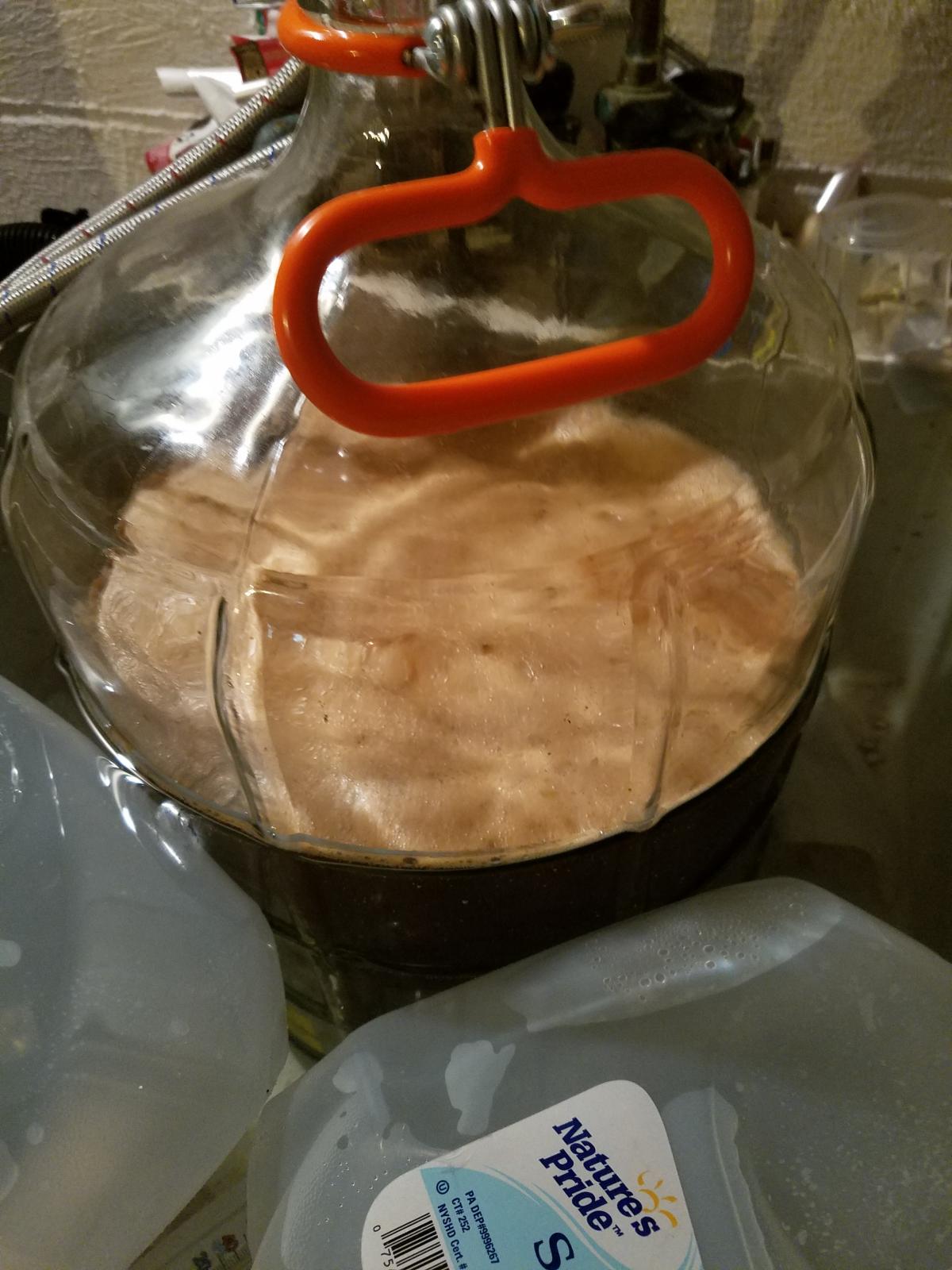

Munich Dunkel!

It went pretty smoothly. Made a mess of the kitchen but maintained the steeping temp pretty well and nothing major went wrong. However, I order my supplies from northern brewer and measuring some of the grains and hops out on my kitchen scale.. it seems like they shorted me on the amounts of stuff. 16oz bags of grain were closer to 12 and I ordered 2oz of hops because I needed 1.3 and 0.5 oz for the 60 and 20 minute additions respectively and ended up with 0.3 on the 20 minute addition.. I hope that doesnt alter the flavor too much.

Also, my brewing pot does not have graduated marks on it and I intended to use my 6.5G carboy for fermenting. So I had to pour the wort into one of my buckets, get it to 5 gallons and then transferred from the bucket to the carboy. I guess that sufficiently aerated it!

Its sitting on 52 degrees right now in a water bath which ill try to maintain for a week or two!

Hopefully I'll have the amber ale that came with the kit cooking within a week or two

It went pretty smoothly. Made a mess of the kitchen but maintained the steeping temp pretty well and nothing major went wrong. However, I order my supplies from northern brewer and measuring some of the grains and hops out on my kitchen scale.. it seems like they shorted me on the amounts of stuff. 16oz bags of grain were closer to 12 and I ordered 2oz of hops because I needed 1.3 and 0.5 oz for the 60 and 20 minute additions respectively and ended up with 0.3 on the 20 minute addition.. I hope that doesnt alter the flavor too much.

Also, my brewing pot does not have graduated marks on it and I intended to use my 6.5G carboy for fermenting. So I had to pour the wort into one of my buckets, get it to 5 gallons and then transferred from the bucket to the carboy. I guess that sufficiently aerated it!

Its sitting on 52 degrees right now in a water bath which ill try to maintain for a week or two!

Hopefully I'll have the amber ale that came with the kit cooking within a week or two

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)