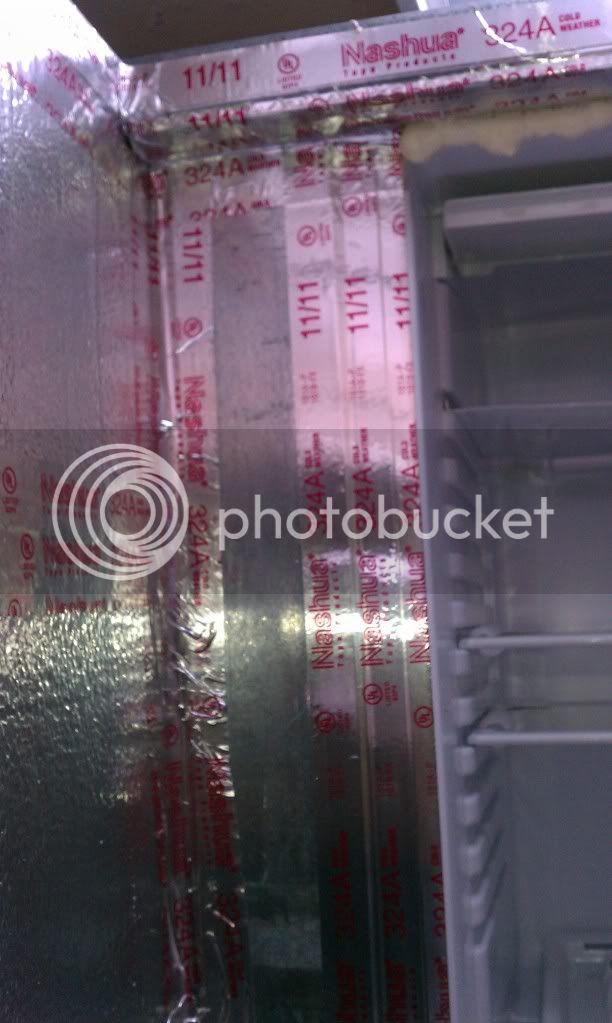

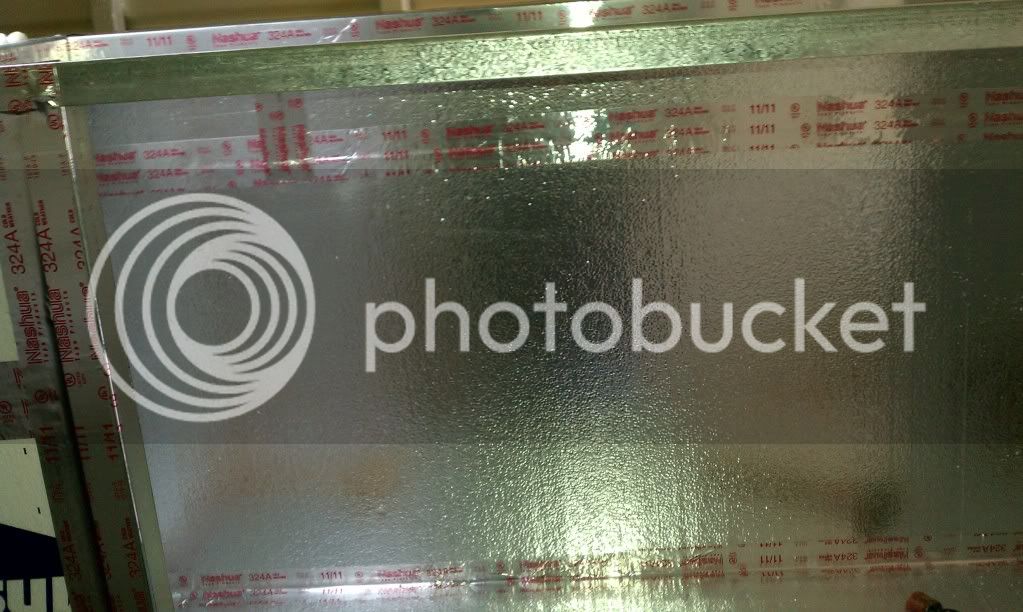

In the process of beginning the fermentation chamber build. Will post progress pics starting tomorrow. Just started today w/ the framing and have a minor question. Chamber is going to be able to house 4 6.5gal carboys, STC-1000 temperature controller (2 stage) w/ a magic chef fridge for cooling. Gonna be a beast.

Have a couple questions questions:

1) My STC-1000 is on its way from over seas (110V version) but it probably won't be here for another week and I'll be done with the grunt of the build. I need to cut out the dimension for the STC...anyone know the actual size of this unit from prior builds?

2) What recommendations do you all have for a heating source? Was thinking the Brewers Edge Heating pad or an actual space heater? Total space is about 6cf.

3) go with a thermawell w/ probe inside one of the carboys or the temp probe inside the actual chamber itself?

Thanks all.

Have a couple questions questions:

1) My STC-1000 is on its way from over seas (110V version) but it probably won't be here for another week and I'll be done with the grunt of the build. I need to cut out the dimension for the STC...anyone know the actual size of this unit from prior builds?

2) What recommendations do you all have for a heating source? Was thinking the Brewers Edge Heating pad or an actual space heater? Total space is about 6cf.

3) go with a thermawell w/ probe inside one of the carboys or the temp probe inside the actual chamber itself?

Thanks all.