grassygrandma

Member

- Joined

- Feb 18, 2022

- Messages

- 10

- Reaction score

- 2

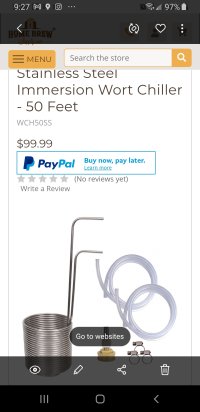

I am adding a cooling system to my 110 gallon fermenter. I am curious about whether it would be more effective to run copper coil around the outside because of sanitation or a stainless steel coil internally for a more effective change in temperature. (Don’t want to put copper inside)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)