I have been struggling with this ever since the LoDo information started circulating. I have always struggled to make IPAs I was happy with, and eventually I decided that it was cold side oxygenation I was dealing with. I have typically done a double dry hop on my IPAs.

What I did on my most recent batch worked well, probably the best IPA I've made. I'm sure plenty of others have adopted a similar technique.

I have started pitching my first dry hop about 3 days into primary ferment, when there is still a fair amount of air lock activity. After 5 days, when fermentation has slowed but not stopped, I transfer. I use my planned serving keg, fill with iodophor most of the way. I remove the quick disconnect, poppet, and dip tube from the gas in port, put the lid on the keg, and siphon more iodophore in through the beer out QD. I keep the keg at an angle, so the gas in port is at the highest point. I pop the pressure relief valve, and wait for sanitizer to come out through the port, then close it. I then wait until sanitizer runs out through the gas in port. I rock the keg back and forth until all the air has come out. I then stop the siphon, and place the dip tube, poppet, and a quick disconnect with an open barb back on. I then restart the siphon and let sanitizer run out through the gas in disconnect, and rock it again to be sure all the air is out. By this time, I figure I have removed the vast majority of air.

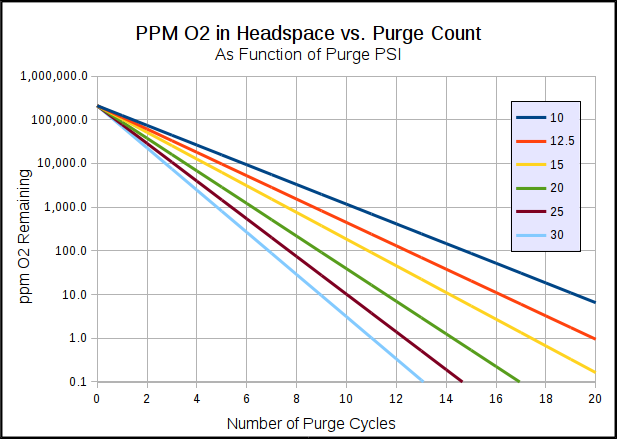

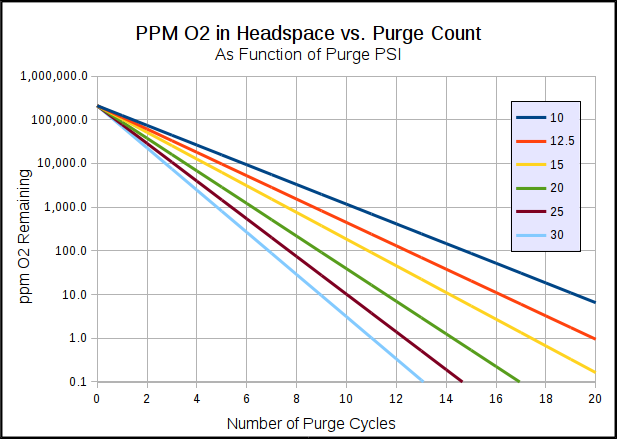

I then push out the iodophor through the beer out port. Now I figure I have a nearly purged keg. I connect the gas through the beer out port and turn it on at about 5 PSI and let it run. I then open the lid, and place the second set of dry hops in a hop bag into the keg. I put the lid back on (CO2 running), and purge at 30 PSI - I think I did 10 purges the last time.

Then, I run the beer, which still has some active fermentation going on, from my Speidel into the keg. I do the same process of putting the keg at an angle and rocking back and forth, until beer comes out the gas in port with no air, and stop the siphon.

I hooked up to gas, and pushed out a bit of beer from the beer out side. I then pressurized to about 3 PSI, took off the pressure relief valve, and added in about 1/4 of the recommended amount of table sugar to keg carbonate. I did this using a large (30mL) syringe, and injecting a preboiled and cooled water/sugar solution through the PRV opening. In my mind, the sugar with the active yeast in suspension would help make sure that whatever O2 was picked up, would hopefully get consumed by the yeast. I was hopeful that this process would not add much oxygen when adding the sugar, but I'm not really sure if it is worth the potential trade off.

I left it at about 68F for 5 days (some time for yeast to work, but not necessarily trying for a fully carbonated keg), then chilled and forced carbonated with CO2. By about 1 week it was tasting great, and has held up fairly well for about 6 weeks now, only losing a bit of the aroma so far.

This may be overkill, and I do not have a DO meter to measure, but this process worked really well for me last time.

Sorry, this post in no way answers your question, but maybe you'll find it useful.

JG