dmcmillen

Well-Known Member

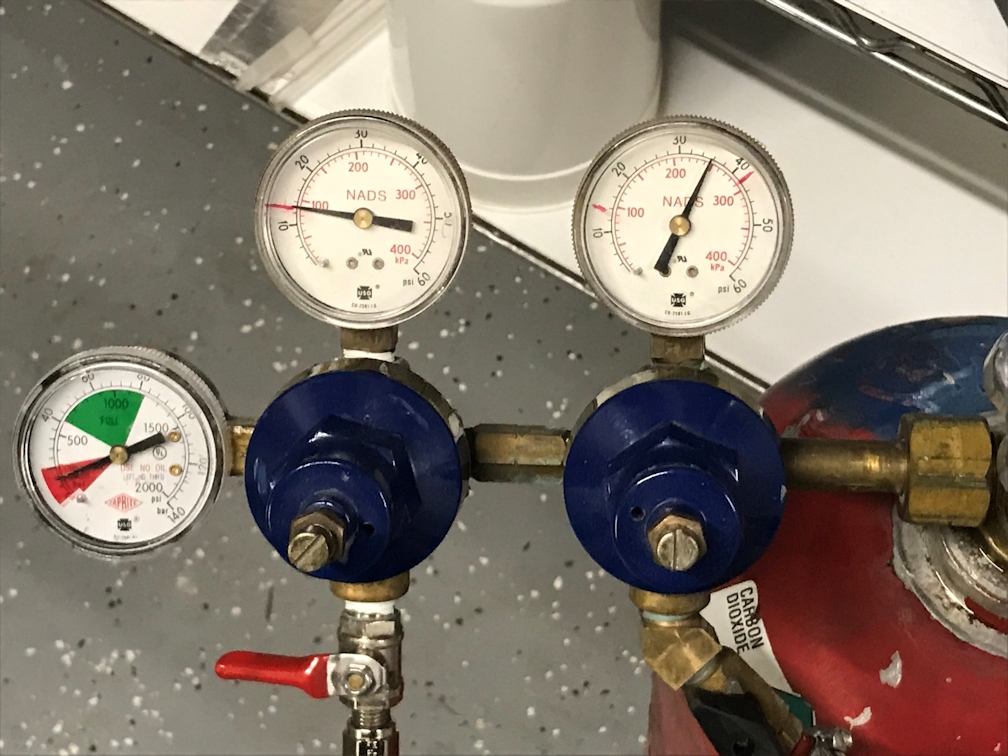

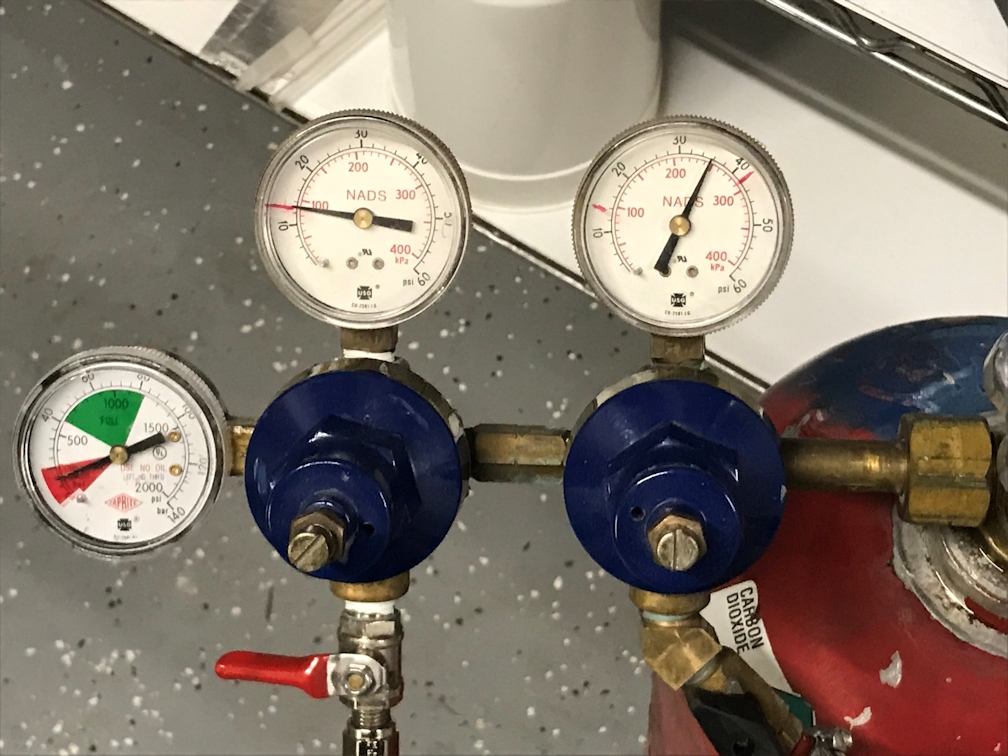

My kegerator has 4 Taparite regulators fed (see 1st pic) from a tank outside of kegerator (see 2nd pic below). I have isolated a slow leak to the middle regulator (see pic) by pressurizing the system and then turning off the gas. At first I thought there wasn't really a leak and it was just the old NADS regulator closest to the tank (see 2nd pic) because the middle Taprite regulator would hold pressure and the needle would slowly go down on the NADS regulator feeding the kegerator, but then I left it pressurized overnight and low and behold the Taprite had dropped from 10 to 5 lbs telling me I have a leak somewhere downstream from that regulator.

First of all I have ordered replacements for the old NADS regulators which will get here in a couple of days. Been wanting to do that for a while.

Secondly, I have repressurized several of times to make sure I have enough pressure at the regulator, and then tested with both starsan and soapy water and a mirror and I'll be damned if I can find any leak. There aren't many places it can be. The only thing that is unusual is that the face of the regulator dial has a very small crack. Not even sure if it is cracked all the way through. I am at my wits end here. The only thing I can think to do is to pull that regulator and reinstall the wye and valves. Any suggestions here?

First of all I have ordered replacements for the old NADS regulators which will get here in a couple of days. Been wanting to do that for a while.

Secondly, I have repressurized several of times to make sure I have enough pressure at the regulator, and then tested with both starsan and soapy water and a mirror and I'll be damned if I can find any leak. There aren't many places it can be. The only thing that is unusual is that the face of the regulator dial has a very small crack. Not even sure if it is cracked all the way through. I am at my wits end here. The only thing I can think to do is to pull that regulator and reinstall the wye and valves. Any suggestions here?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)