Islandboy85

Well-Known Member

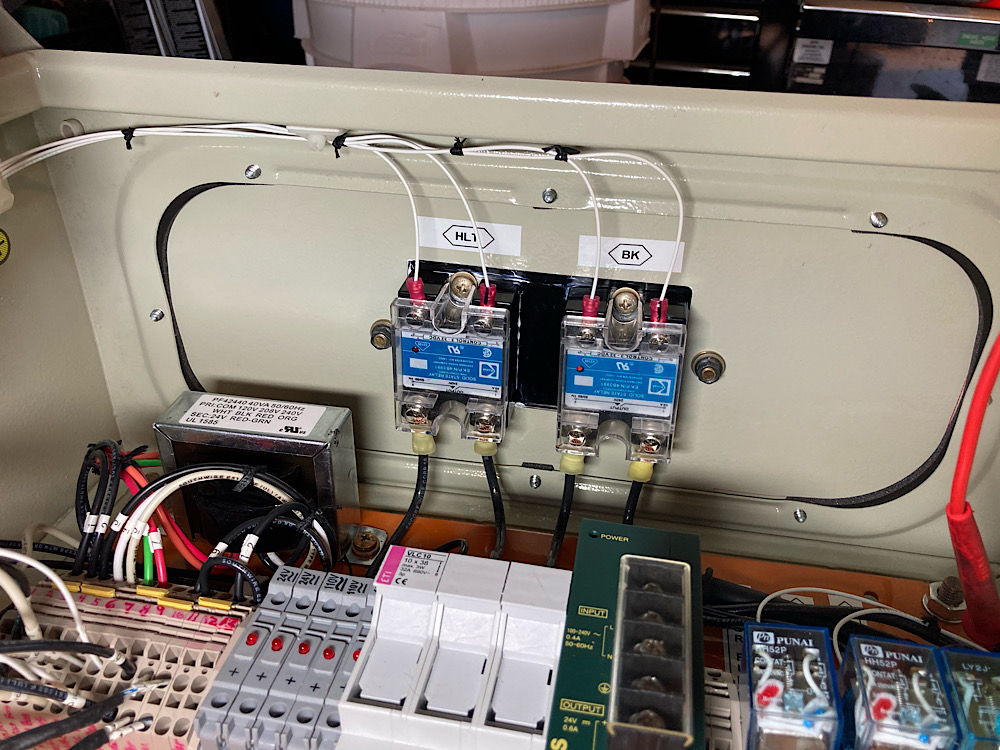

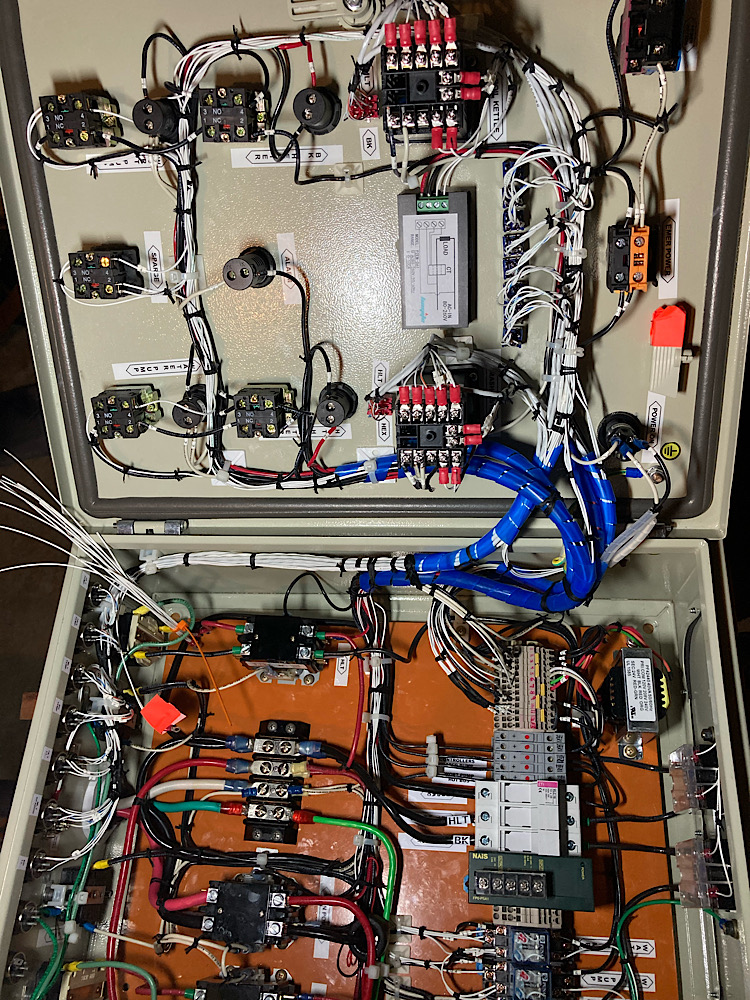

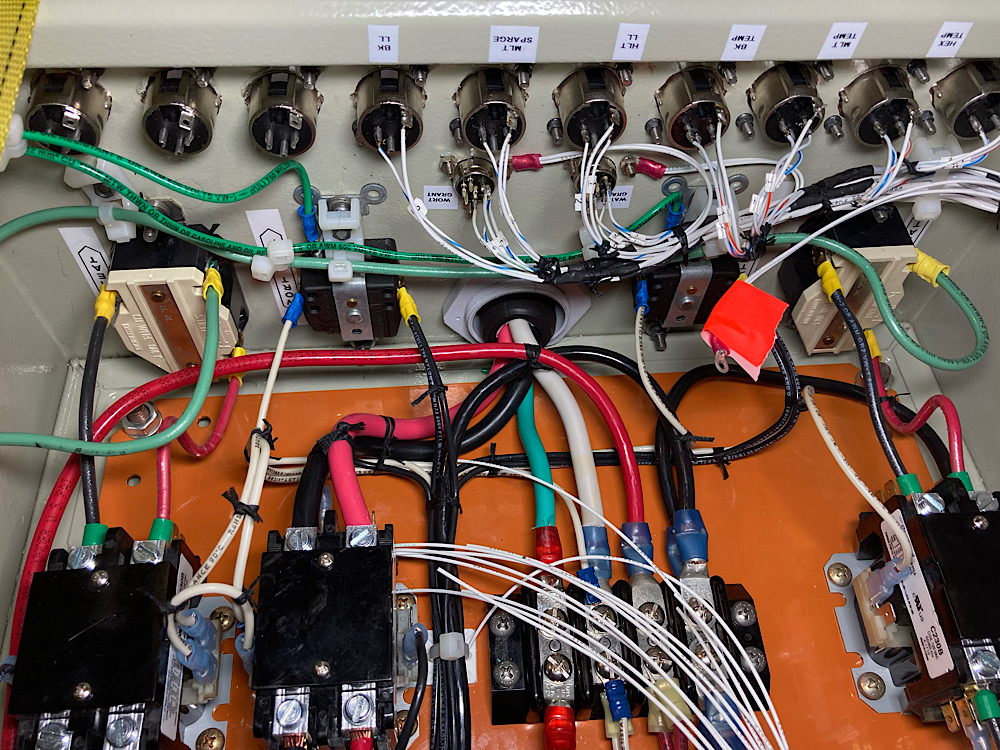

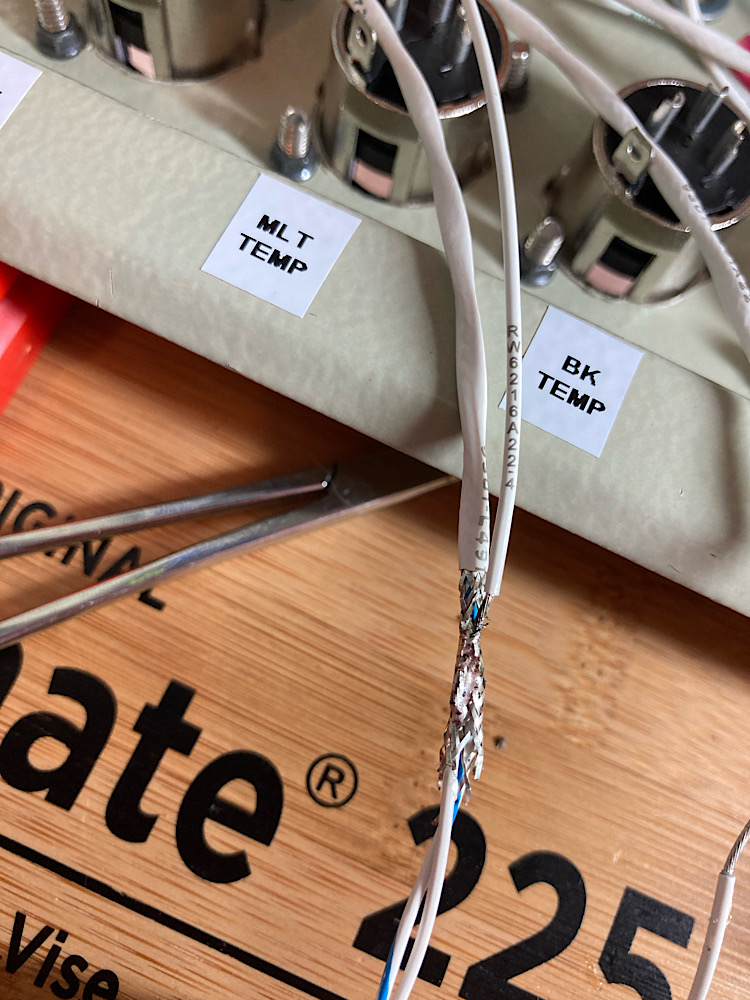

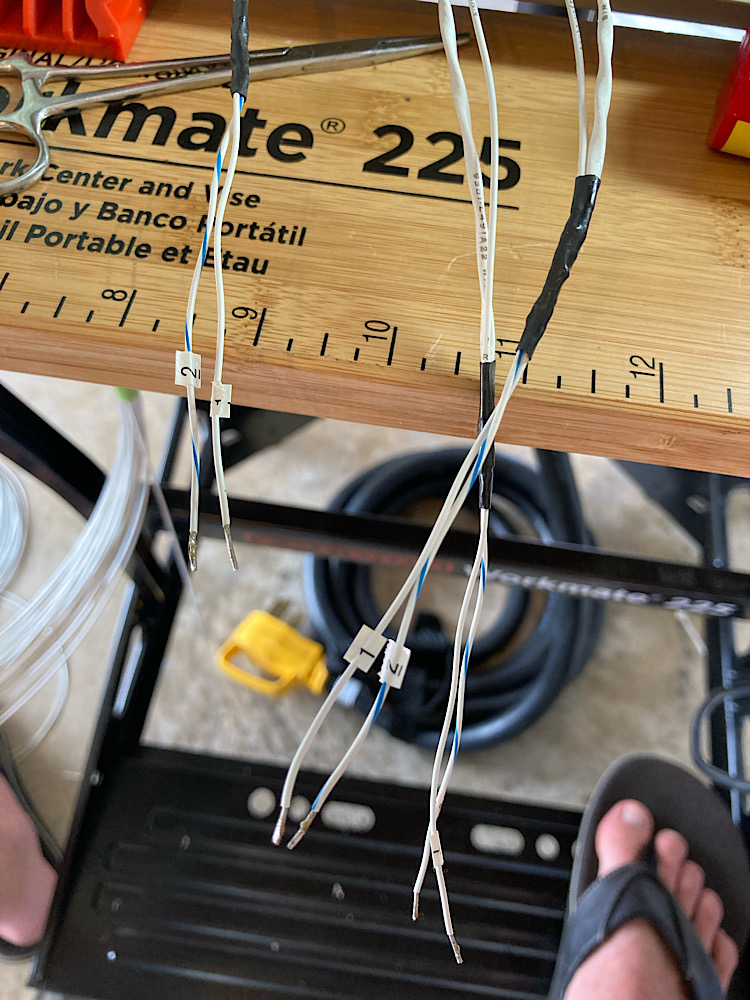

Got holes cut for the XLR receptacles for temp sensors and float switches. And most of the panel components located. The heating element receptacles took a bit to get righgbsince I needed a hole a bit larger than 1-3/8, but the largest punch I had was 1-1/4. A little work with a half round file, and Im pretty happy. View attachment IMG_4702.jpg

View attachment IMG_4703.jpg

View attachment IMG_4703.jpg

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)