You have read a roller coaster of my learning curve with electric

On post 1 there are some link you can jump to relevant sections of my thread (FYI)

No problem! I have my drawings in visio, but I don't have them on hand this second. Did you want the drawings for one side or for the entire enclosure (both sides). Would you mind pming your email to me?

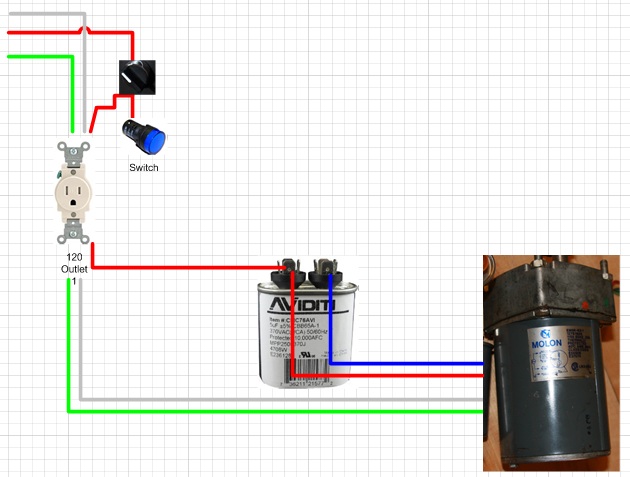

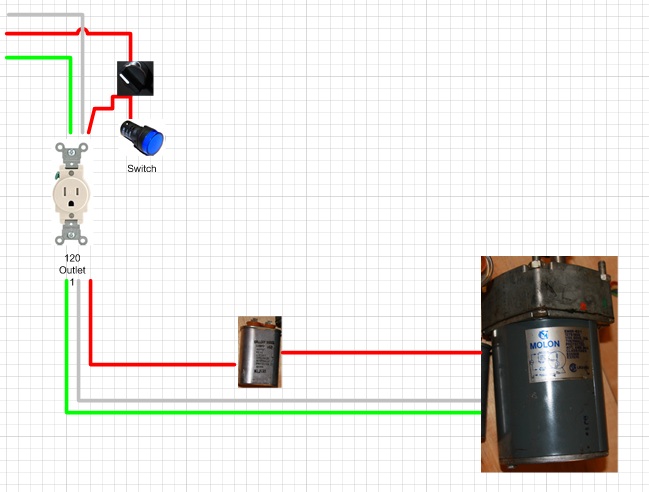

FYI - I ran through the wiring schematics and the final product with my brother in law (licensed union electrician). So while I am not an electrician the concepts on paper and in the box were reviewed by at least one (had help from a couple others on as well).

It is certainly a little more $$ to go with the two 30 amp gfi feeds. However that is mostly a factor of the 30 amp GFIs that you have to buy. Aside from that if you get your enclosure on ebay with that free shipping on other items deal... you really aren't spending a ton more money on hardware to get two simultaneously running elements (IMO obviously well worth it).

If you need help figuring out why I did what I did, feel free to ask and we can even chat via phone if that works better for you.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

)

)