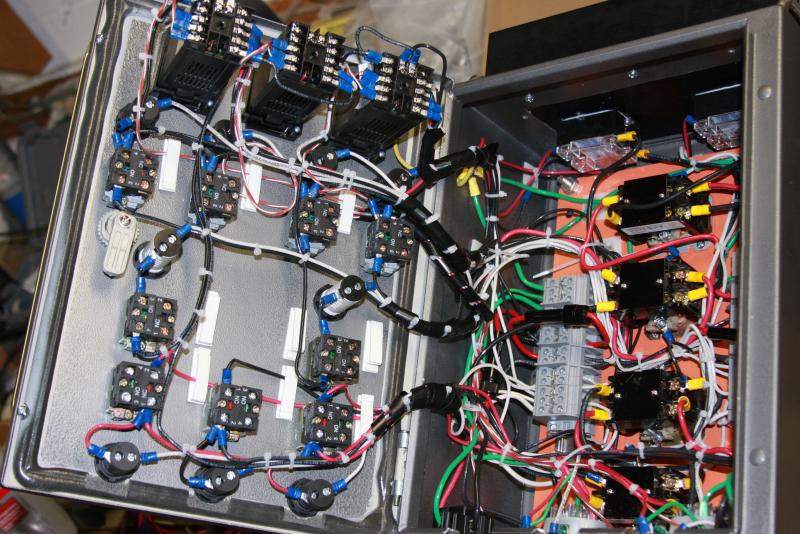

I measured all the stuff out, then checked clearances with measure, then with actual parts in place and looks like I will have plenty of space. The space will require me to keep things neatly wired, but that is part of the beauty of the electrical rigs. Nice neat and secured wiring!If I went with the larger box I think it would have been too much space. I like the current layout I have because it isn't over crowded, but uses up the space on the panel.

Can't wait to settle up the painting and then to get the hardware in place for wiring. Still waiting on my switches from china though.... suckers. now they are past due and it would really suck to have them refund me with no switches in hand. Hopefully they come in this week right after I get the painting done.

the cool part about the receptacles is that with the current set up I will have the ability to have 3 120 outlets. 2 are spoken for with pumps with one unclaimed. This will either be for a third pump down the road, a ventilation hood fan or a mechanical stirrer for the HLT when I complete my eherms.

I will have to come down for a brew day when your all up and running!!! Will be interesting to see and I can always bring down 4.5 lbs of grain to add to the batch!! LOL

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)