You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Efficiency Complaint Department

- Thread starter sbsmann

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I've dumped it all in, dumped it through a paint strainer bag, and reserved the last 32 (or so) oz - mostly depending on how close I got to my desired volume, but mood and alignment of the stars all play a part. The only difference I've been able to tell is that the yeast is much nicer to harvest from the batches where I didn't just dump it in.

It seems like the sort of thing that Brulosophy would be all over but I can't check their website from work.

It seems like the sort of thing that Brulosophy would be all over but I can't check their website from work.

No, the OG is the OG. No matter what happens before, or how you reach it. It's the Original Gravity. If you add water to dillute the SG, the new SG will be the OG.

True. But, here's how I see the issue. Let's say that you tell beersmith that you have a brewhouse efficiency of 70%. This number includes how much wort you (do or do not) throw out. If you leave wort in your kettle your brewhouse efficiency drops. This is why I asked about brewhouse v. mash.

Bottom line, leaving behind a gallon of wort hurts your bh efficiency. So . . . you lie to your software and say, my brewhouse efficiency is 70%, it says, ok with all that water and grain at 70% efficiency here's how much grain you need to use. But, your brewhouse efficiency is not 70%. Leaving out a gallon of wort to get to 5 means you are losing 1 gallon of the six you made. That alone is a 17% loss in efficiency. Add in all the other factors, such as mash eff, and there you are.

Consider you mash efficiency. That is the number that tells you how you did on your mash. Is that number good? If so, then you are doing great with your mash (grist crush, stirring, pH, etc., etc.) After that, your decision to throw out good wort is just fine. Just realize that it impacts your BH eff. Set your BH eff correctly in the software, and watch yourself hit your OG.

I do know that BH eff is affected by collecting wort. What I don't know for certain if it is this simple. But, I suspect this is a good illustration. Just looking at mash eff of 80%. Take that by 83% (throwing out a gallon out of the six you have). That is 66.4%. I'm guessing that doesn't account for a few other losses.

http://beersmith.com/blog/2008/10/26/brewhouse-efficiency-for-all-grain-beer-brewing/

Again, I hope I'm helping. I frustrated myself with this same issue until I realized that I was doing just fine on what I was getting out of my grain, and that I was OK with throwing away perfectly good wort (to the detriment of my BH eff).

And FWIW, I started allowing more kettle trub into my fermenter. Apparently good for the yeast (hearsay, sorry). And, when I cold crash, I compact all that fluffy kettle trub and can get more wort into my keg out of the same starting quantity.

This is exactly why I don't like doing comparisons using BH efficiency. It's more about volume losses post mash then how good your mash and lauter process is.True. But, here's how I see the issue. Let's say that you tell beersmith that you have a brewhouse efficiency of 70%. This number includes how much wort you (do or do not) throw out. If you leave wort in your kettle your brewhouse efficiency drops. This is why I asked about brewhouse v. mash.

Bottom line, leaving behind a gallon of wort hurts your bh efficiency. So . . . you lie to your software and say, my brewhouse efficiency is 70%, it says, ok with all that water and grain at 70% efficiency here's how much grain you need to use. But, your brewhouse efficiency is not 70%. Leaving out a gallon of wort to get to 5 means you are losing 1 gallon of the six you made. That alone is a 17% loss in efficiency. Add in all the other factors, such as mash eff, and there you are.

Consider you mash efficiency. That is the number that tells you how you did on your mash. Is that number good? If so, then you are doing great with your mash (grist crush, stirring, pH, etc., etc.) After that, your decision to throw out good wort is just fine. Just realize that it impacts your BH eff. Set your BH eff correctly in the software, and watch yourself hit your OG.

I do know that BH eff is affected by collecting wort. What I don't know for certain if it is this simple. But, I suspect this is a good illustration. Just looking at mash eff of 80%. Take that by 83% (throwing out a gallon out of the six you have). That is 66.4%. I'm guessing that doesn't account for a few other losses.

http://beersmith.com/blog/2008/10/26/brewhouse-efficiency-for-all-grain-beer-brewing/

Again, I hope I'm helping. I frustrated myself with this same issue until I realized that I was doing just fine on what I was getting out of my grain, and that I was OK with throwing away perfectly good wort (to the detriment of my BH eff).

And FWIW, I started allowing more kettle trub into my fermenter. Apparently good for the yeast (hearsay, sorry). And, when I cold crash, I compact all that fluffy kettle trub and can get more wort into my keg out of the same starting quantity.

Playing with OP's numbers 13.5 lb grain, 7.25 gal pre-boil, 6.15 gal post-boil, 5.15 gal to fermenter, and assuming an efficient fly sparge, I come up with the following:

- At 100% conversion efficiency, your pre-boil SG should have been about 1.059, mash and lauter efficiency would have been about 89%, and OG would have been about 1.069 - 1.070.

- To get your actual OG of 1.056, your mash efficiency was about 72%, and if your sparge was done well, that would put your conversion efficiency at about 80%, which is pretty low. Of course if your sparge was in any way deficient, then your conversion efficiency could have been higher, and your lauter efficiency less than the 89% - 90% it should have been.

- Leaving a gallon in your BK gives you a transfer efficiency of 100% * 5.15 gal / 6.15 gal = 84%, and your BH efficiency was about 100% * 0.84 * 0.72 = 60% - 61%.

- 69% mash efficiency and an OG of 1.064.

- Since everything went into the fermenter, transfer efficiency is 100% and BH efficiency is 69%

Brew on

While crush can be a big part of it, I have had a lot of success by tweaking my fly sparge practices.

1) I've read fly sparges should be near 45 minutes in length. When I've tried to rush I've notices a significant drop in efficiency.

2) When I first started fly sparging I was leaving an inch or two of water over the bed and pouring/pumping straight into the water. I believe this was channeling. What I've started employing is a steamer basket from one of my kitchen pots suspended above the water line. I then pump my sparge water into that basket causing it to drip fairly evenly across the surface.

Doing these two things brought my efficiency from struggling around high 60's all the way up to 80+ depending on the grain bill.

1) I've read fly sparges should be near 45 minutes in length. When I've tried to rush I've notices a significant drop in efficiency.

2) When I first started fly sparging I was leaving an inch or two of water over the bed and pouring/pumping straight into the water. I believe this was channeling. What I've started employing is a steamer basket from one of my kitchen pots suspended above the water line. I then pump my sparge water into that basket causing it to drip fairly evenly across the surface.

Doing these two things brought my efficiency from struggling around high 60's all the way up to 80+ depending on the grain bill.

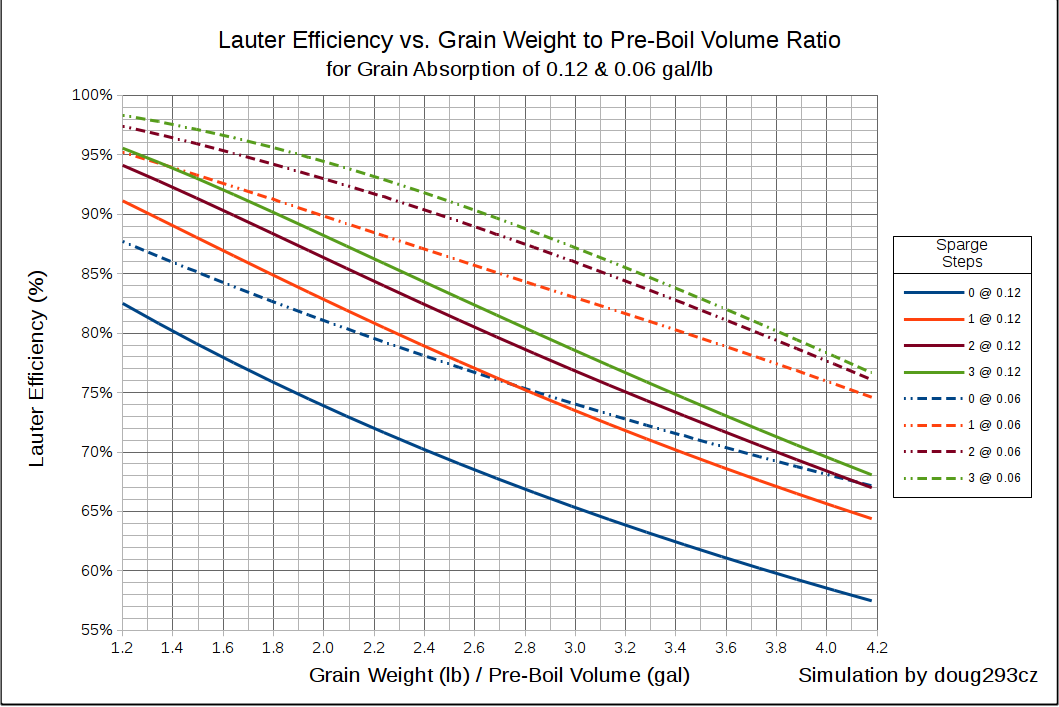

To know for sure if your low mash efficiency is due to poor conversion efficiency or poor lauter (fly sparge) efficiency, you can measure your conversion efficiency directly by using the method here. If your conversion efficiency is less than 90% you really need to work on that (crush finer, mash longer, pH control, etc.) 100% conversion is achievable with a fine crush, and 95% is a good target. If your conversion efficiency is good, but your mash efficiency isn't, then you need to look at your sparging process. A really well conducted fly sparge can beat the 3X batch sparge curve (solid green line) by a couple of percentage points.While crush can be a big part of it, I have had a lot of success by tweaking my fly sparge practices.

1) I've read fly sparges should be near 45 minutes in length. When I've tried to rush I've notices a significant drop in efficiency.

2) When I first started fly sparging I was leaving an inch or two of water over the bed and pouring/pumping straight into the water. I believe this was channeling. What I've started employing is a steamer basket from one of my kitchen pots suspended above the water line. I then pump my sparge water into that basket causing it to drip fairly evenly across the surface.

Doing these two things brought my efficiency from struggling around high 60's all the way up to 80+ depending on the grain bill.

Brew on

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

sbsmann

Well-Known Member

This is really interesting and seems to make a good case for reducing some of my water volumes and just dumping everything in the fermenter. I'm going to have to look at my numbers closer, but it's starting to look like they aren't quite as bad as I originally thought as far as mash efficiency. The fact I throw away a gallon of sludge is a bit irresponsible IMO!This is exactly why I don't like doing comparisons using BH efficiency. It's more about volume losses post mash then how good your mash and lauter process is.

Playing with OP's numbers 13.5 lb grain, 7.25 gal pre-boil, 6.15 gal post-boil, 5.15 gal to fermenter, and assuming an efficient fly sparge, I come up with the following:

Now if we look at the case where you put everything from the BK into your fermenter, you would only need 6.25 gal pre-boil to net the same 5.15 gal in the fermenter. Working with the same 80% conversion efficiency as above, I come up with:

- At 100% conversion efficiency, your pre-boil SG should have been about 1.059, mash and lauter efficiency would have been about 89%, and OG would have been about 1.069 - 1.070.

- To get your actual OG of 1.056, your mash efficiency was about 72%, and if your sparge was done well, that would put your conversion efficiency at about 80%, which is pretty low. Of course if your sparge was in any way deficient, then your conversion efficiency could have been higher, and your lauter efficiency less than the 89% - 90% it should have been.

- Leaving a gallon in your BK gives you a transfer efficiency of 100% * 5.15 gal / 6.15 gal = 84%, and your BH efficiency was about 100% * 0.84 * 0.72 = 60% - 61%.

So, low conversion efficiency (think crush too coarse) hurt your mash efficiency and BH efficiency. You could still have made your target OG if you had started with less water (and pre-boil volume) and not left ~1 gal in your BK.

- 69% mash efficiency and an OG of 1.064.

- Since everything went into the fermenter, transfer efficiency is 100% and BH efficiency is 69%

Brew on

homebrewer_99

Well-Known Member

- Joined

- Feb 1, 2005

- Messages

- 19,581

- Reaction score

- 1,223

- Location

- I-80, Exit 27 (near the Quad Cities)

Maybe I should just dump all the sludge, etc into the fermenter and then I think my problem is solved and I get closer (maybe above) to 70%?

Like bleme, I strain my chilled wort through a nylon net on it's way to the primary. I'm sure "some" break get through, but the harvested yeast is very clean. I just wash it to to get everything in suspension. Once it starts collecting at the bottom I pour off most of the liquid that I know is yeast and toss the rest. There's no reason to get greedy about the process since there is more than enough to collect.

homebrewer_99

Well-Known Member

- Joined

- Feb 1, 2005

- Messages

- 19,581

- Reaction score

- 1,223

- Location

- I-80, Exit 27 (near the Quad Cities)

I strain my wort through a nylon net as it drains into the primary. It catches everything while aerating the wort.

There ya go. I used to worry about sludge into fermenter. After reading some stuff here and a brulosophy test or two, I realized it may not matter. Been brewing for twenty plus years. Honestly, I tend to believe the idea that some of that gunk is good for the yeast. I have a pretty good palate, I have no problems with it.This is really interesting and seems to make a good case for reducing some of my water volumes and just dumping everything in the fermenter. I'm going to have to look at my numbers closer, but it's starting to look like they aren't quite as bad as I originally thought as far as mash efficiency. The fact I throw away a gallon of sludge is a bit irresponsible IMO!

As far as calling it irresponsible, meh. Just get happy by hitting OG and go from there. Or change your bh in the software and buy a few bucks of grain more. If you can spare the cash, who cares. I'll say it since I started with the book almost 24 years ago RDWHAHB. Happy retirement Charlie!

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

True. But, here's how I see the issue. Let's say that you tell beersmith that you have a brewhouse efficiency of 70%. This number includes how much wort you (do or do not) throw out. If you leave wort in your kettle your brewhouse efficiency drops. This is why I asked about brewhouse v. mash.

Bottom line, leaving behind a gallon of wort hurts your bh efficiency. So . . . you lie to your software and say, my brewhouse efficiency is 70%, it says, ok with all that water and grain at 70% efficiency here's how much grain you need to use. But, your brewhouse efficiency is not 70%. Leaving out a gallon of wort to get to 5 means you are losing 1 gallon of the six you made. That alone is a 17% loss in efficiency. Add in all the other factors, such as mash eff, and there you are.

Consider you mash efficiency. That is the number that tells you how you did on your mash. Is that number good? If so, then you are doing great with your mash (grist crush, stirring, pH, etc., etc.) After that, your decision to throw out good wort is just fine. Just realize that it impacts your BH eff. Set your BH eff correctly in the software, and watch yourself hit your OG.

I do know that BH eff is affected by collecting wort. What I don't know for certain if it is this simple. But, I suspect this is a good illustration. Just looking at mash eff of 80%. Take that by 83% (throwing out a gallon out of the six you have). That is 66.4%. I'm guessing that doesn't account for a few other losses.

Don't think about brewhouse efficiency. That number is imo pretty useless as it only tells you how much wort is not making it through the pipeline.

Since you use Beersmith (I guess?). You input your losses, and manipulate the brewhouse efficiency so estimated mash efficiency is equal to your expected mash efficiency. The mash efficiency is what's important. If you leave a lot of wort behind you need to make a bigger wort, since some wort doesn't make it. By diluting with water to hit the volume your SG/OG will go down. By using more water and malt (basically making more wort of the correct SG), and if your losses are correctly entered into Beersmith, you will end up with a correct OG and Volume.

Last edited:

YeastHerder

Well-Known Member

Does OP recall seeing any still intact grain kernels? If you saw one in a handful, I'd wager your crush was not good enough.

Low and variable efficiency, and variable grain crush via the LHBS mill, are the main reasons I bought my own mill.

Now, I can go all tinfoil hat conspiracy theory here and suggest that a looser setting and thus lower efficiency from the LHBS mill means you need to buy more grain from them to hit your target. But that would be crazy talk.. At any rate, I bought my own mill and there are so many bonuses that come with that: buy unmilled grain in bulk for lower per lb price, unmilled grain shelf-life is way longer than crushed, having your own mill means set it to whatever pleases you -- overall it is well worth the investment.

Low and variable efficiency, and variable grain crush via the LHBS mill, are the main reasons I bought my own mill.

Now, I can go all tinfoil hat conspiracy theory here and suggest that a looser setting and thus lower efficiency from the LHBS mill means you need to buy more grain from them to hit your target. But that would be crazy talk.. At any rate, I bought my own mill and there are so many bonuses that come with that: buy unmilled grain in bulk for lower per lb price, unmilled grain shelf-life is way longer than crushed, having your own mill means set it to whatever pleases you -- overall it is well worth the investment.

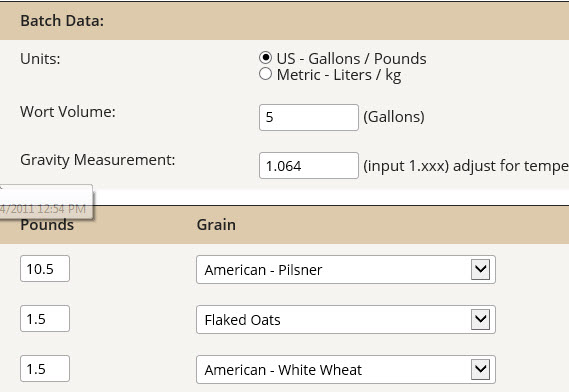

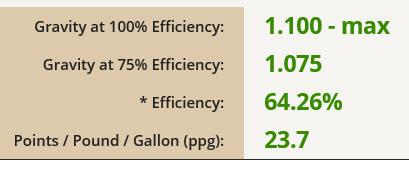

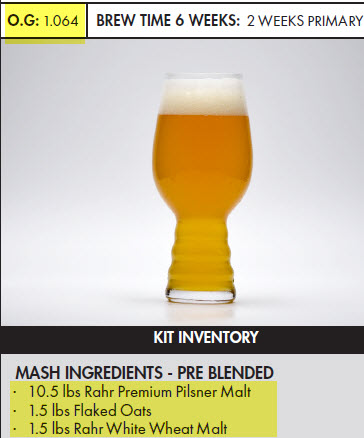

sbsmann

Well-Known Member

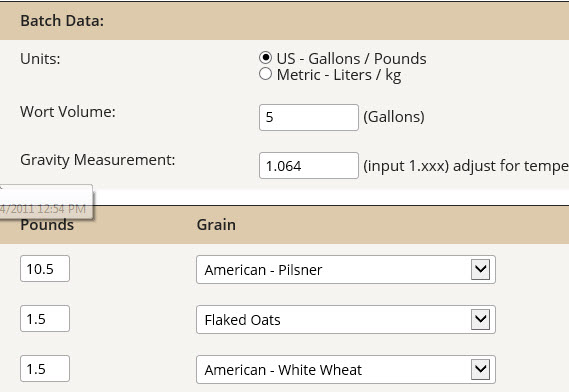

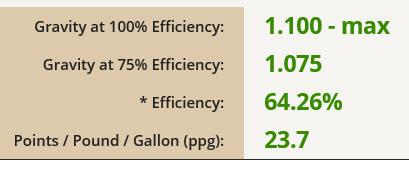

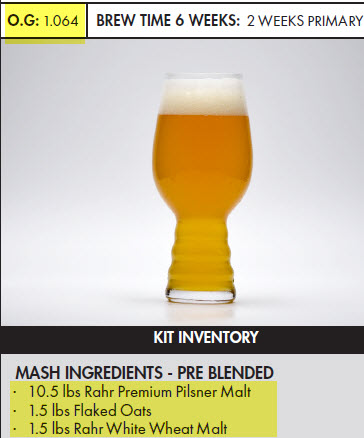

After more analysis and studying, my numbers look better than I originally thought (I think) if I look at pre-boil & ending kettle efficiencies. I do seem perplexed by Northern Brewer’s OG of 1.064. If I look at the brewhouse efficiency calculator from Brewersfriend (https://www.brewersfriend.com/brewhouse-efficiency/) and I use the data below in my printscreens, I come up with a OG of 1.075 @ 75%. That means Northern Brewer is estimating people should be getting only 64% efficiency from this grain bill? Doesn’t that seem inaccurate or did I make a mistake in the calculator using the wrong grains or something wacky?

chickypad

lupulin shift victim

Their kit instructions don't seem to specify but I'm guessing they are figuring for 70% efficiency with a 5.5 gal post boil batch size. That would get most people about 5 gals finished if everything is dumped in the fermenter, and would match the 1.064 target OG listed. So you see why it's important to adjust every all grain recipe for your own system and volumes. Like other mentioned I would target the post boil efficiency and not the brewhouse efficiency, which may change batch to batch depending on losses. On the Brewer's friend site it would be what they are calling "Ending kettle efficiency". Figure out how much volume you want in the kettle post boil and chill and plug that number in as your volume.

Similar threads

- Replies

- 24

- Views

- 2K

- Replies

- 6

- Views

- 894

- Replies

- 7

- Views

- 767

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)