OatStraw

Well-Known Member

So I've decided to go electric. I've been contemplating this for a long time and been doing a TON of research. If you've seen the master thread of all of PJs diagrams I put together then you have an idea of how long I've been thinking about this.

I debated wether or not I would do HERMS or keep using the cooler system that I already had. I've decided to continue using my cooler as the Mash Tun since it's been working and I haven't had any issues with losing temperature.

[/IMG]

[/IMG]

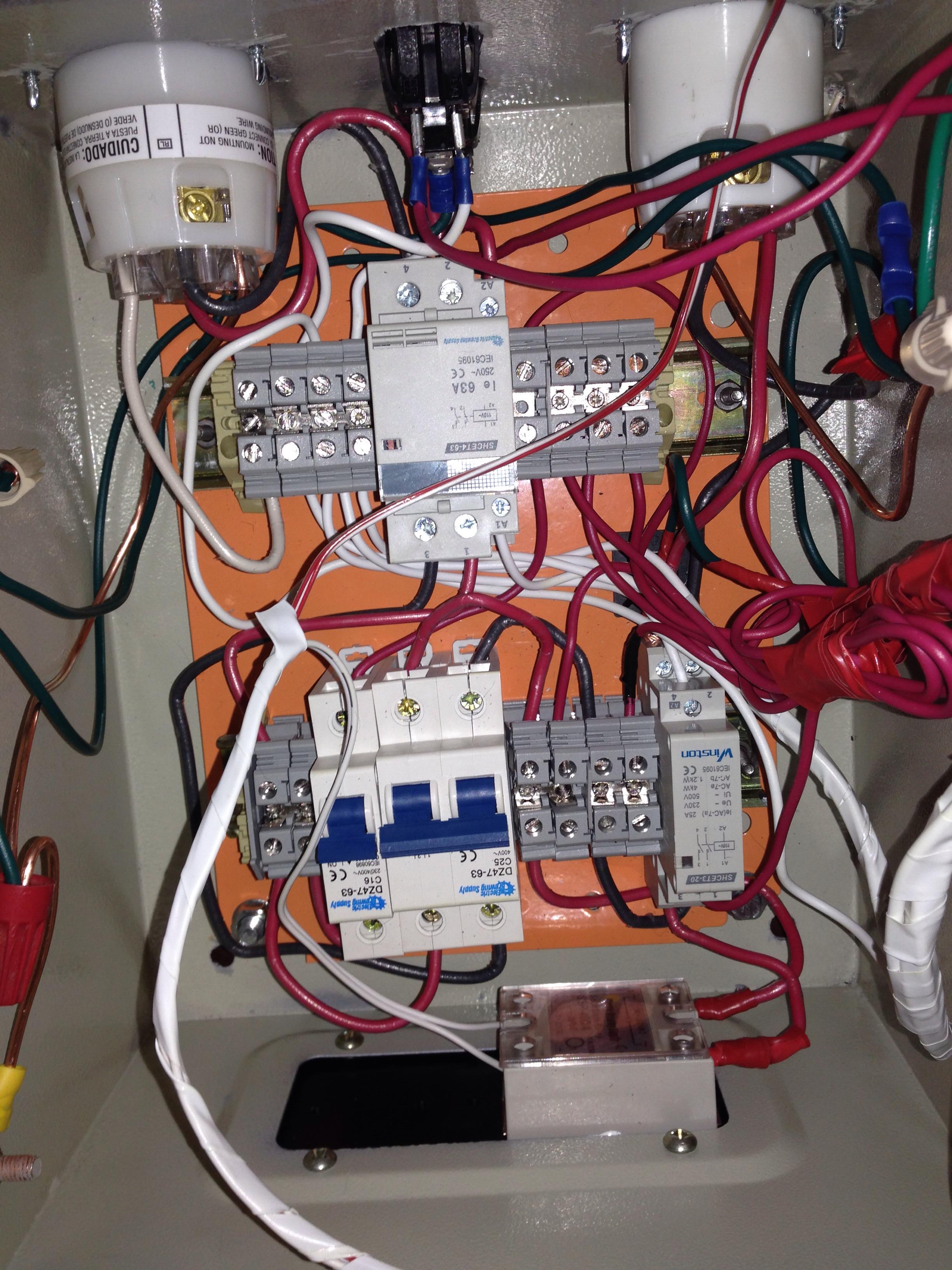

Both of the Keggles will be converted to run 5500w heating elements. These are in the mail and I will receive them today.

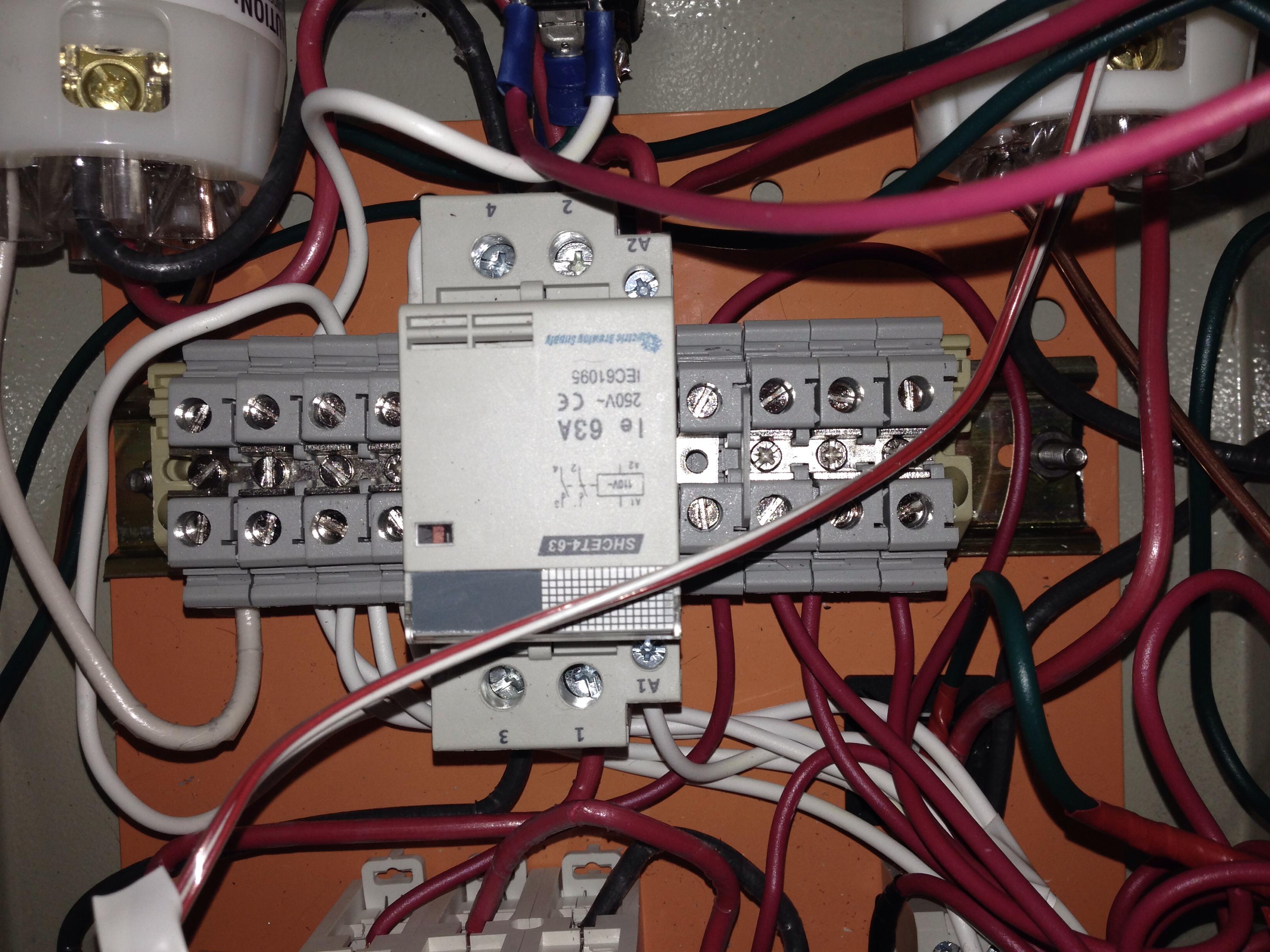

For the control panel I decided to go with ebrewsupply.com and purchase their 30A eBIAB kit. Since I won't be doing a recirculating mash I have no need for 2 PIDs, and do not need to be able to have both elements plugged in at the same time (especially since on 30A they can't both run at the same time). So this BIAB kit is perfect for my needs, all I will have to do is switch which element is plugged in and put the PID into manual mode for the boil. Won't even need a 2nd temperature probe.

I'm still playing with the panel layout, and will have to order the buzzer (pictured as the red circle) and a reset button.

[/IMG]

[/IMG]

I will post a list of where I got all my materials tonight. One assumption I made early on was that making one of these control panels would be cheaper than buying High Gravity's EBC SV. I think it will be REALLY close.

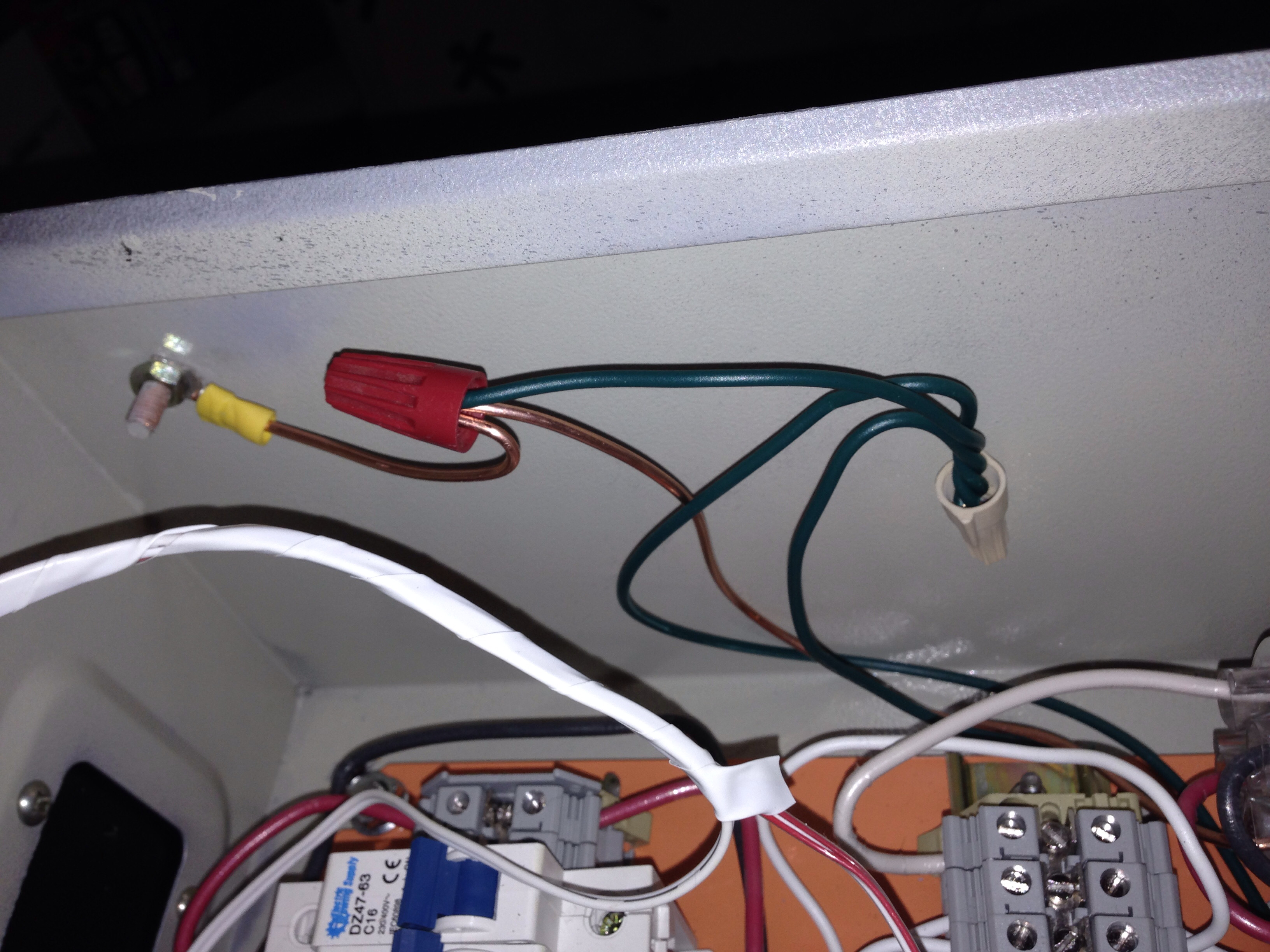

One area that I am kind of nervous about is the wiring. The kit came with DIN rails and DIN rail terminal blocks (with all the accessories). I have no idea how these work or interact with each other, so if you know of any builds that have used these please let me know!

I debated wether or not I would do HERMS or keep using the cooler system that I already had. I've decided to continue using my cooler as the Mash Tun since it's been working and I haven't had any issues with losing temperature.

Both of the Keggles will be converted to run 5500w heating elements. These are in the mail and I will receive them today.

For the control panel I decided to go with ebrewsupply.com and purchase their 30A eBIAB kit. Since I won't be doing a recirculating mash I have no need for 2 PIDs, and do not need to be able to have both elements plugged in at the same time (especially since on 30A they can't both run at the same time). So this BIAB kit is perfect for my needs, all I will have to do is switch which element is plugged in and put the PID into manual mode for the boil. Won't even need a 2nd temperature probe.

I'm still playing with the panel layout, and will have to order the buzzer (pictured as the red circle) and a reset button.

I will post a list of where I got all my materials tonight. One assumption I made early on was that making one of these control panels would be cheaper than buying High Gravity's EBC SV. I think it will be REALLY close.

One area that I am kind of nervous about is the wiring. The kit came with DIN rails and DIN rail terminal blocks (with all the accessories). I have no idea how these work or interact with each other, so if you know of any builds that have used these please let me know!