DJP00829

Ice Cold Brewer

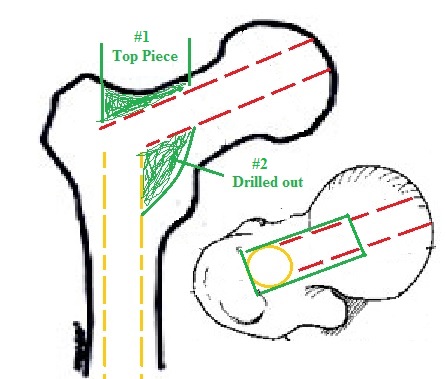

So I have this idea for a custom draft tower and I cant seem to find anything similar, so I was hoping to get some input on how people think it might work / if it'd be worth pursuing. The MSPaint Concept:

Yes, those are bones, but dont worry, they're plastic. My main concern with the project is stability and making everything fit/work. I was planning on securing the bones to each other where they cross - thinking about lashing them together with some stronger fishing line because I doubt there would be enough room for a screw and wouldn't want to ruin the aesthetics by using a bracket.

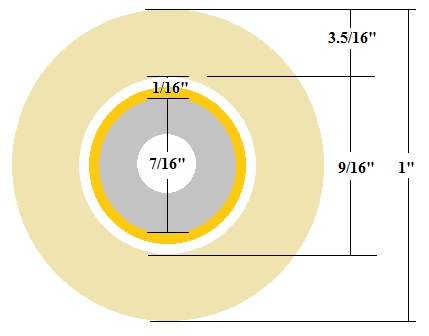

A big issue is that I don't currently have the bones in my possession. But I've been told they're about an inch in diameter at the thinnest, solid plastic, fairly sturdy. So given that the OD of vinyl tubing is 7/16", I was thinking 1/2" copper tubing for a heat sync (should give me about 1/32" of wiggle room on the inside). And then I was debating if I could get away with a 9/16" hole. Schematic:

I feel like this would leave me with the most stability while shoving everything in to the limited space.

Another difficulty with not having the bones is that I dont know if a faucet shank will fit in the head. As for anchoring the towers, I was thinking of mounting the bone over a PVC flange, maybe some angled elbows, since there's a little more room at the bottom.

These would be at a bit more of an angle, but you get the idea.

Any suggestions?

Cheers!

Yes, those are bones, but dont worry, they're plastic. My main concern with the project is stability and making everything fit/work. I was planning on securing the bones to each other where they cross - thinking about lashing them together with some stronger fishing line because I doubt there would be enough room for a screw and wouldn't want to ruin the aesthetics by using a bracket.

A big issue is that I don't currently have the bones in my possession. But I've been told they're about an inch in diameter at the thinnest, solid plastic, fairly sturdy. So given that the OD of vinyl tubing is 7/16", I was thinking 1/2" copper tubing for a heat sync (should give me about 1/32" of wiggle room on the inside). And then I was debating if I could get away with a 9/16" hole. Schematic:

I feel like this would leave me with the most stability while shoving everything in to the limited space.

Another difficulty with not having the bones is that I dont know if a faucet shank will fit in the head. As for anchoring the towers, I was thinking of mounting the bone over a PVC flange, maybe some angled elbows, since there's a little more room at the bottom.

These would be at a bit more of an angle, but you get the idea.

Any suggestions?

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)