Morrey

Well-Known Member

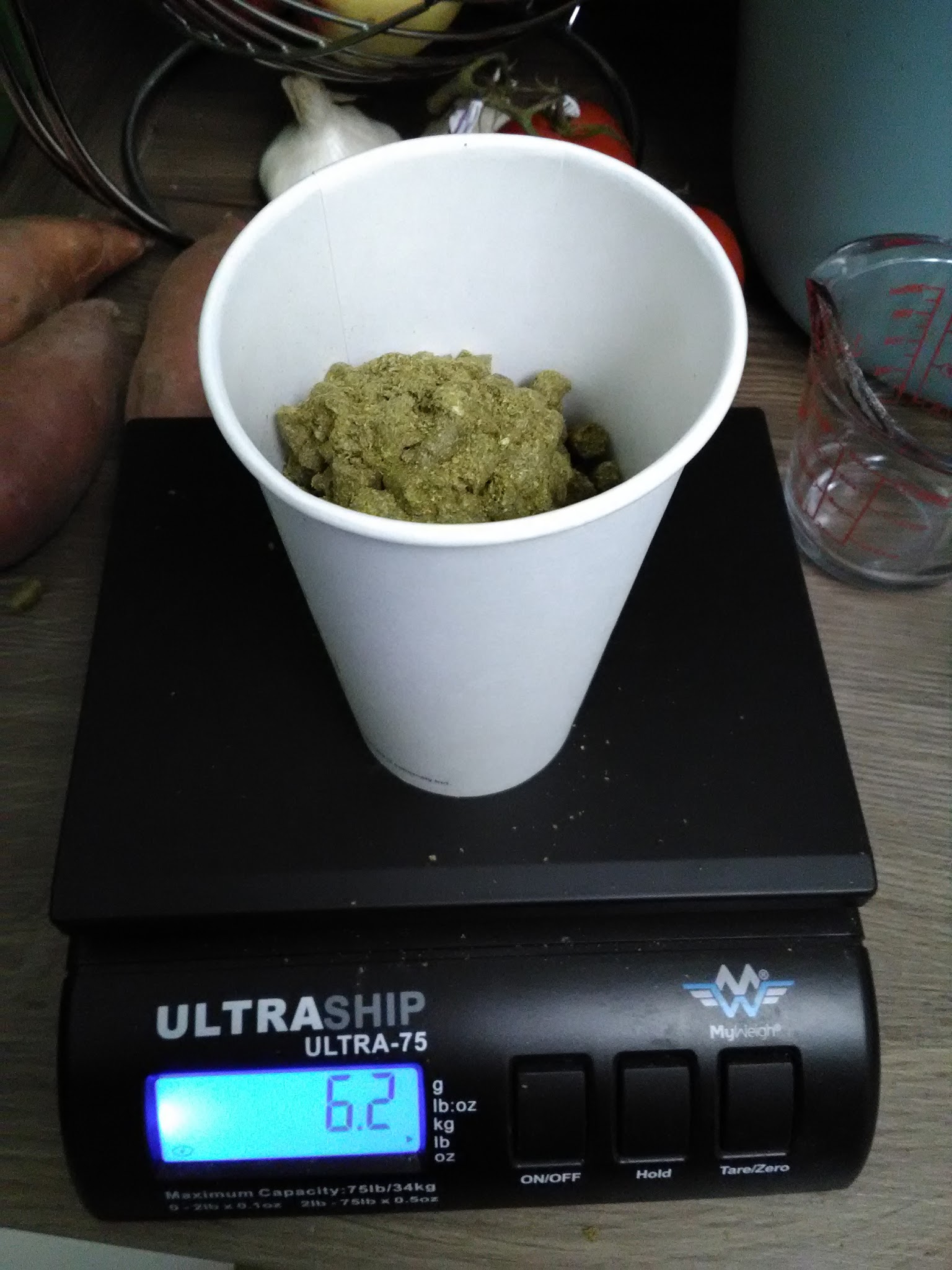

Just took a hydro sample and then dropped a few dryhops in. Any of you planning on using a basket or anything? I used to do bags in my old conicals but they'd sometimes block the racking valve. I'd tie it with some floss and run it up the lid, reach in and grab that out if it happened. Dont really want to do that since no O2 on dank eepahs is the goal. My experience with dryhops settling during cold crash is pretty hit or miss. Think Ill just go for it and see if I wind up with any clogged dip tubes.

For dry hopping, I have an Arbor Fab mesh dry hop tube with a cap that is suspended by a chain and hook. I took a 3" TC blank end cap and tack welded a bracket on the underside to hang the chain and suspend the tube mid-level. The tube measures 2.75" in diameter so it fits perfectly down into the 3" port on top. The cooling coils keep the hop tube from blocking anything, plus the chain and hook keep the tube suspended and out of the way of any openings that may otherwise get blocked.

Of course opening the tank's 3" port allows some O2 exposure as we are all trying to avoid. Conversely many big breweries just open a hatch and dump hops in, so at least we are not the lone strangers out there allowing in minimal O2 exposure.

Just a thought: Do you think there may any value to connecting a CO2 line to the BO tube and running CO2 thru the racking cane while we took the 3" port off the top to dry hop? This may not be 100% effective, but a flow of CO2 over the top of the beer may keep O2 from entering the tank as rapidly. Thoughts?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)