GreenEnvy22

Well-Known Member

- Joined

- Sep 17, 2015

- Messages

- 183

- Reaction score

- 183

Hi all,

I've done a few extract kits over the years but going to do my first all grain, 5 gallon batch. I bought a 48qt cooler and built a manifold with CPVC. I don't have a kettle yet, but do have some large stainless pots my wife and I use for canning. The larger 35+ liters, other is around 25. I don't have a propane burner yet, but my gas stove has 5 burners, I think I can get 2-3 of them under the pot.

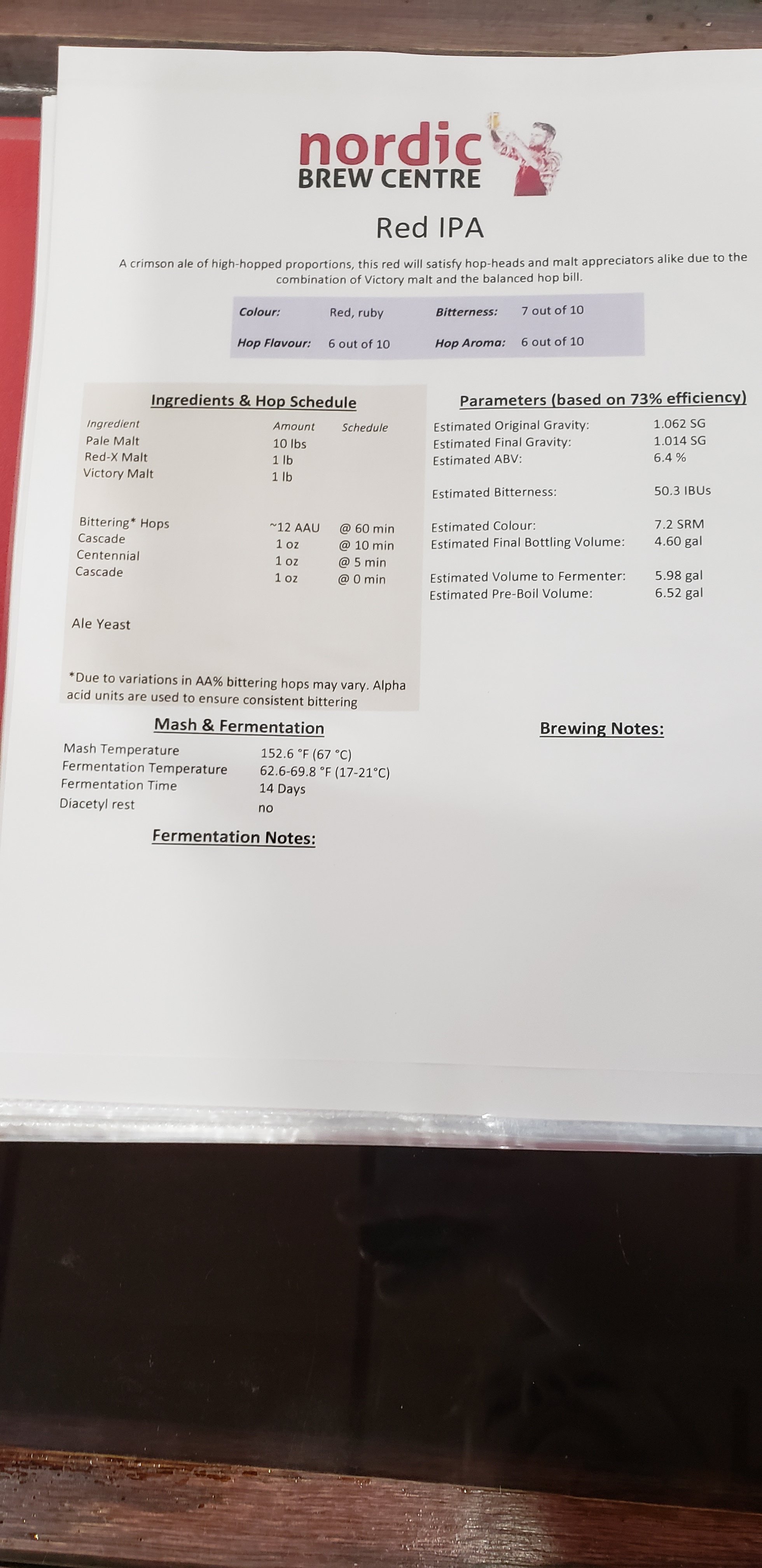

I grew my own Chinook and cascade hops which I just harvested and dried this week. I'll use those for my first brew. Going to try to make a red IPA. Recipe is 10lbs Pale malt, 1lb red-x, 1lb victory. Recipe calls for Cascade and Centennial. I'd substitute the centennial for my Chinook, will be interesting to see what that does.

For cooling I'll just be putting the big stainless pot into a large laundry sink. I'll get a immersion cooler down the road. I have a nice bluetooth digital thermometer with 4 probes for monitoring temps.

I've been making wine from fresh grapes for years so hopefully some of that translates over.

Anyway, just wanted to say Hi. If anyone has any tips, I'm all ears.

I've done a few extract kits over the years but going to do my first all grain, 5 gallon batch. I bought a 48qt cooler and built a manifold with CPVC. I don't have a kettle yet, but do have some large stainless pots my wife and I use for canning. The larger 35+ liters, other is around 25. I don't have a propane burner yet, but my gas stove has 5 burners, I think I can get 2-3 of them under the pot.

I grew my own Chinook and cascade hops which I just harvested and dried this week. I'll use those for my first brew. Going to try to make a red IPA. Recipe is 10lbs Pale malt, 1lb red-x, 1lb victory. Recipe calls for Cascade and Centennial. I'd substitute the centennial for my Chinook, will be interesting to see what that does.

For cooling I'll just be putting the big stainless pot into a large laundry sink. I'll get a immersion cooler down the road. I have a nice bluetooth digital thermometer with 4 probes for monitoring temps.

I've been making wine from fresh grapes for years so hopefully some of that translates over.

Anyway, just wanted to say Hi. If anyone has any tips, I'm all ears.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)