I've just been working on a little attempt at using a normal refractometer 'inline' so that I can measure the brix

of the wort during mashing and sparging.

Today I just conducted a simple test heating water from around 17C to just below 70C before the pi crashed, I believe because of how I'd positioned it too close to the refractometer.

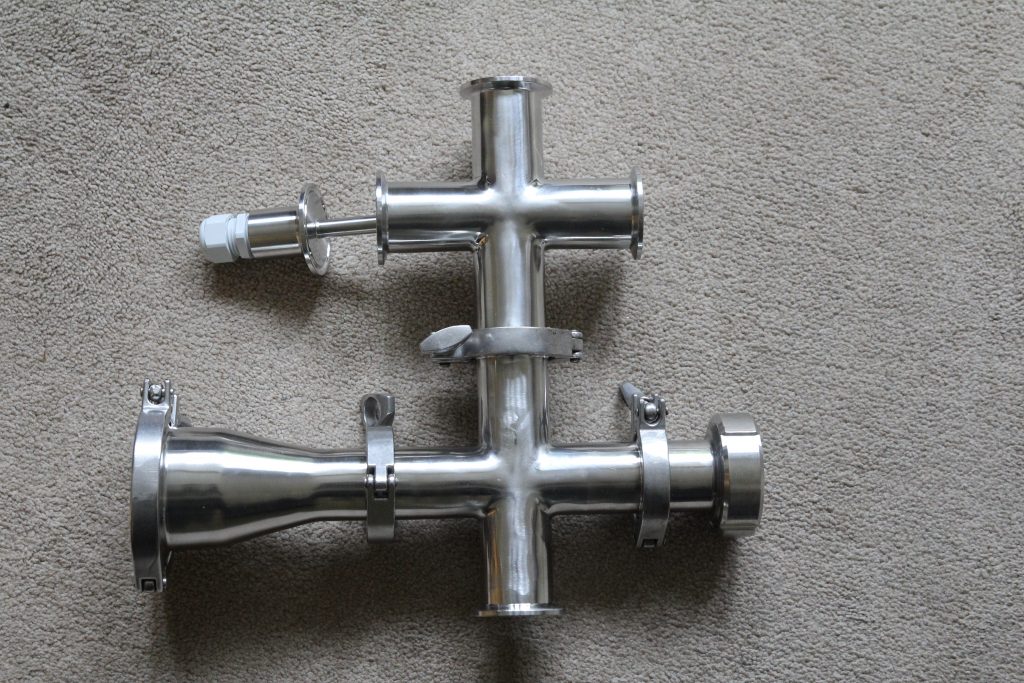

I'm going to redesign the prototype using triclamp fittings (2x 4-way triclamp fittings, with a sight glass on the end of one) in an effort to mitigate some slight leaks (note, the gland attached to the refractometer didn't seem to leak though).

I'm going to convert the blue line to a digital brix reading, using some simple image processing.

https://www.anfractuosity.com/projects/diy-inline-refractometer/

I also need to alter the shutter speed I set, as it gets too dark near the end of the video.

of the wort during mashing and sparging.

Today I just conducted a simple test heating water from around 17C to just below 70C before the pi crashed, I believe because of how I'd positioned it too close to the refractometer.

I'm going to redesign the prototype using triclamp fittings (2x 4-way triclamp fittings, with a sight glass on the end of one) in an effort to mitigate some slight leaks (note, the gland attached to the refractometer didn't seem to leak though).

I'm going to convert the blue line to a digital brix reading, using some simple image processing.

https://www.anfractuosity.com/projects/diy-inline-refractometer/

I also need to alter the shutter speed I set, as it gets too dark near the end of the video.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)