You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Grainfather/BIAC style build

- Thread starter Compacto

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

OneManBrewery

Well-Known Member

Nice build. It's like the Chippendales version of the Grainfather.

DarkStormBrewing

Well-Known Member

Last post the pics didn't work, any more updates? Very interesting build.

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

Brew day with the new features! Sparge system worked out really well. A Bavarian Wheat using WLP300, first time using White Labs. Had a hard time getting Wyeast 3068 where I wanted it (big esters, big banana flavor) so giving this one a try, supposedly very similar yeasts.

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

Last post the pics didn't work, any more updates? Very interesting build.

Updated, think they should work now.

Bellybuster

Well-Known Member

- Joined

- Aug 3, 2007

- Messages

- 905

- Reaction score

- 170

what a great system.

can you tell us what the inner basket holding your bag is??

can you tell us what the inner basket holding your bag is??

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

what a great system.

can you tell us what the inner basket holding your bag is??

Thanks!

It's a Bayou steamer basket from their 44qt kit. Pretty solid for BIAB setups. Tops out at ~25Lbs grain.

DarkStormBrewing

Well-Known Member

Thanks! This build is inspiring. I'm surprised that the homebrew market hasn't adopted tri clamps as the standard. I'm fed up with threads and 3 piece ball valves. I'm on a conquest to change all of my threaded to tri clamp, for ease of cleaning. It's not just bling for me.

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

Thanks! This build is inspiring. I'm surprised that the homebrew market hasn't adopted tri clamps as the standard. I'm fed up with threads and 3 piece ball valves. I'm on a conquest to change all of my threaded to tri clamp, for ease of cleaning. It's not just bling for me.

I am too. Threaded fittings stick around likely because they can be fit to kettles without welding. I'd love to see one of the pump manufacturers put out a TC pump head though.

WPStrassburg

Well-Known Member

I am too. Threaded fittings stick around likely because they can be fit to kettles without welding. I'd love to see one of the pump manufacturers put out a TC pump head though.

There was one place that I remember seeing a March 5 series with TC connections on it, but it looks like your welding skills are good enough to do what I had done and just tack a few on yourself.

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

Another test brew on the system. Finally figured out a method for verifying volume so did a test brew trying to make sure I could hit all my numbers. Gravity was still a bit wonky. Seem to be getting 63% without sparging. Is that normal to you other BIABers?

Also, a question for refractometer users, what're your methods for taking readings? I seem to get ones that are all over the board. ie it climbs and falls during the mash...? I'm recirculating so I can count out a non homogeneous mash. It's only two or three drops so it cools in seconds. And I've calibrated it with distilled water.

Any other ideas?

A bit of descrpency in internal grain and mash temps.

Also, a question for refractometer users, what're your methods for taking readings? I seem to get ones that are all over the board. ie it climbs and falls during the mash...? I'm recirculating so I can count out a non homogeneous mash. It's only two or three drops so it cools in seconds. And I've calibrated it with distilled water.

Any other ideas?

A bit of descrpency in internal grain and mash temps.

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

Hello!

Got a bunch more fabrication done last night in hope I can brew over the holiday weekend.

Progress: I (finally) got the wheels on which should make the whole brewing process loads easier. Welded another TC port on the kettle for the whirlpool/stirring inlet.

This time of year with the ground water 64º I can knock out to ~66º in one pass through the CFC so I typically do that straight into fermentor and that knocks a good 25 minutes off my brewday. But when I brew a beer where I want to leave sediment behind I'll put it to use. But during the brew it serves the dual purpose of stirring the wort as I heat to boil. That way as soon as mash is over, I can swing the sparge arm over to the whirlpool inlet, turn the pump on, begin stirring the wort to not scorch it, turn the coils on, yank the basket, rest it atop the kettle and begin sparging. This was I can go from mash end to boil in 22 minutes (last batch with 10.5 gallons).

One of my big goals for this build was to shorten the brew day. This past sunday, from filling the kettle to pitching the yeast it was 4 hours and 25 minutes for a 10g batch (60min mash, 60 min boil). I'm hoping with the new features and ones to come I can get it around 3:30 for 12g.

Plate for the feet

Got to love the Edwards Iron Worker. Punching through 0.25" 304 is a walk in for park for that machine.

Whirlpool/stir arm

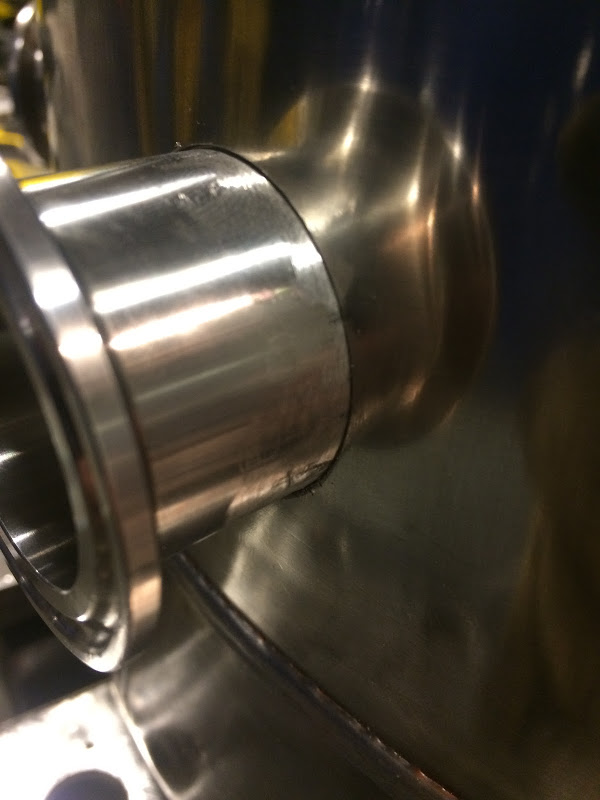

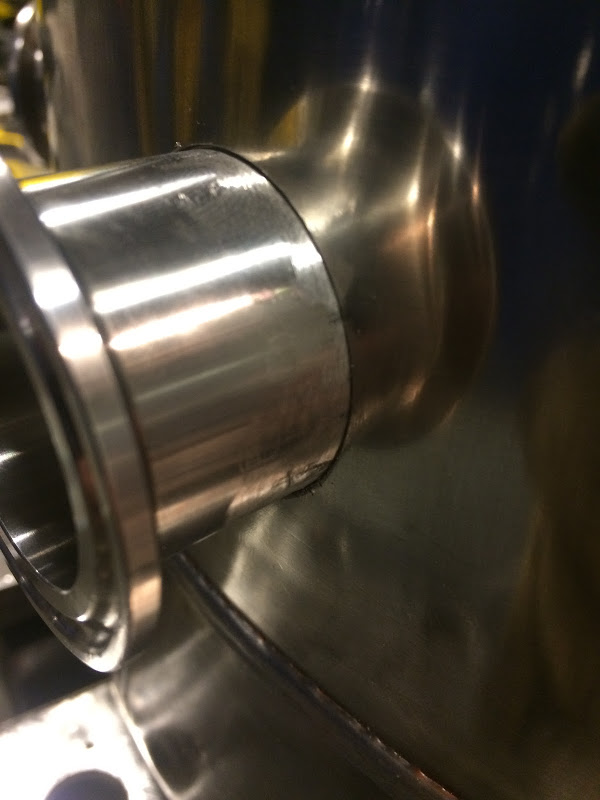

Port fit up. I've tried about five different methods for putting ports on kettles. If you're going to weld one on. I think the best way is to buy a hole saw the same size as the ID of your TC fitting. Drill the kettle, the TC port won't fit right away, take a file and ream it until you can forcibly jam the port into the hole which will ensure good fit up. Then weld away. If you can fit your head on the inside, weld both. If not, the outside wild do with a back purge. Perhaps solder the inside afterwards.

Here are the different configurations for brewing-

Mash

Sparge/ heat to boil

And cooling/ draining after cleaning.

Yet To Do -

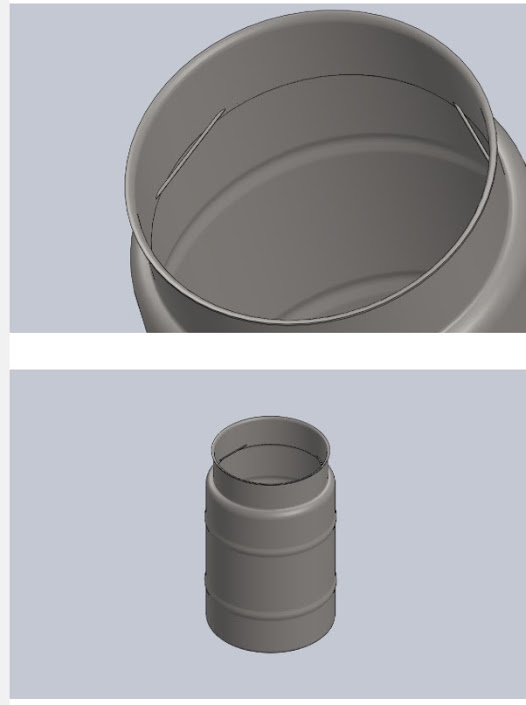

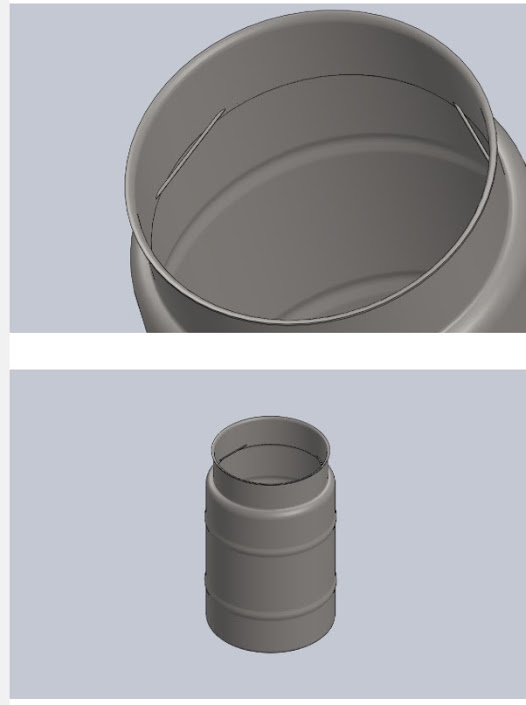

As I've become a bit obsessive about shortening the brewday the whole bag part of the BIAB thing is a bit of a pain. Been thinking of fabricating a bag-less grain basket. It would also allow for the grains to sit fully in the water as about 3" is exposed with the current basket. Also an increased grain capacity would be well used. We'll see, that mush SS is expensive ...

Got a bunch more fabrication done last night in hope I can brew over the holiday weekend.

Progress: I (finally) got the wheels on which should make the whole brewing process loads easier. Welded another TC port on the kettle for the whirlpool/stirring inlet.

This time of year with the ground water 64º I can knock out to ~66º in one pass through the CFC so I typically do that straight into fermentor and that knocks a good 25 minutes off my brewday. But when I brew a beer where I want to leave sediment behind I'll put it to use. But during the brew it serves the dual purpose of stirring the wort as I heat to boil. That way as soon as mash is over, I can swing the sparge arm over to the whirlpool inlet, turn the pump on, begin stirring the wort to not scorch it, turn the coils on, yank the basket, rest it atop the kettle and begin sparging. This was I can go from mash end to boil in 22 minutes (last batch with 10.5 gallons).

One of my big goals for this build was to shorten the brew day. This past sunday, from filling the kettle to pitching the yeast it was 4 hours and 25 minutes for a 10g batch (60min mash, 60 min boil). I'm hoping with the new features and ones to come I can get it around 3:30 for 12g.

Plate for the feet

Got to love the Edwards Iron Worker. Punching through 0.25" 304 is a walk in for park for that machine.

Whirlpool/stir arm

Port fit up. I've tried about five different methods for putting ports on kettles. If you're going to weld one on. I think the best way is to buy a hole saw the same size as the ID of your TC fitting. Drill the kettle, the TC port won't fit right away, take a file and ream it until you can forcibly jam the port into the hole which will ensure good fit up. Then weld away. If you can fit your head on the inside, weld both. If not, the outside wild do with a back purge. Perhaps solder the inside afterwards.

Here are the different configurations for brewing-

Mash

Sparge/ heat to boil

And cooling/ draining after cleaning.

Yet To Do -

As I've become a bit obsessive about shortening the brewday the whole bag part of the BIAB thing is a bit of a pain. Been thinking of fabricating a bag-less grain basket. It would also allow for the grains to sit fully in the water as about 3" is exposed with the current basket. Also an increased grain capacity would be well used. We'll see, that mush SS is expensive ...

OneManBrewery

Well-Known Member

I haven't changed my mind, I want one of these. Great build.

Stillraining

Well-Known Member

Spent a few hours polishing. Forgot how much a love polishing stainless :cross:

Your not right in the head boy!...

Very cool build!

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

Hello!

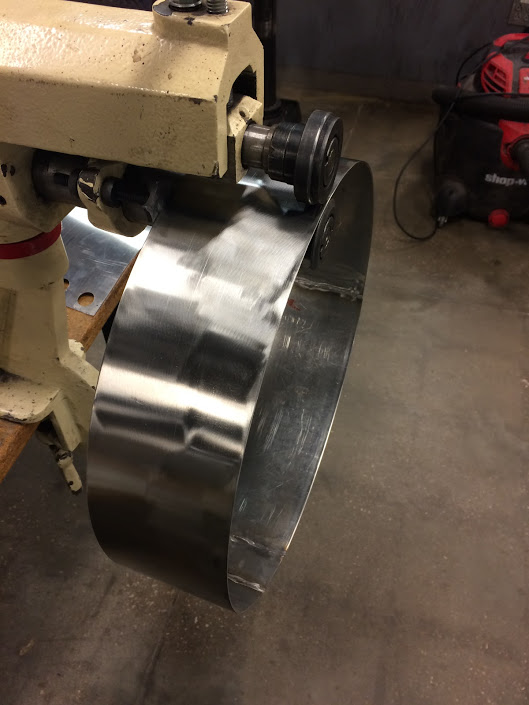

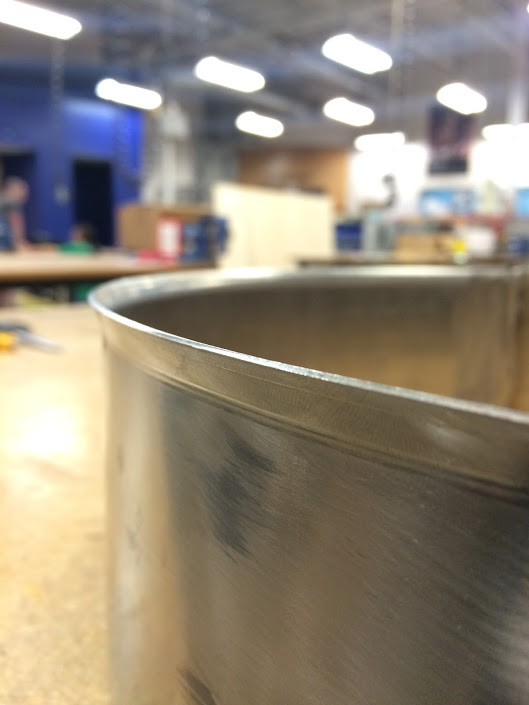

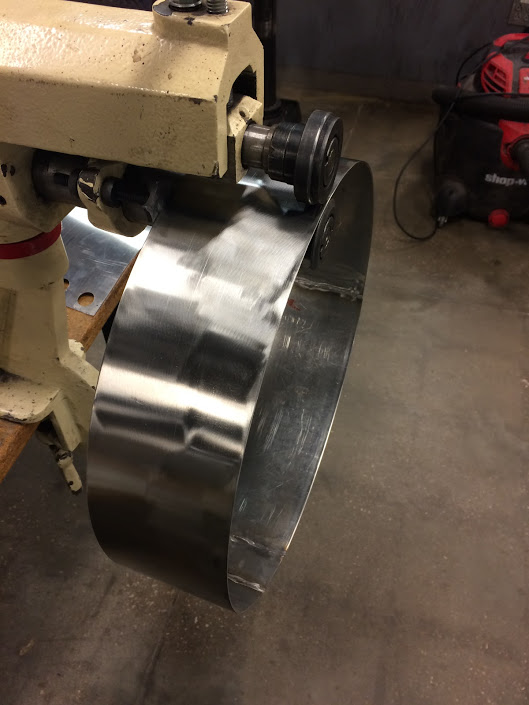

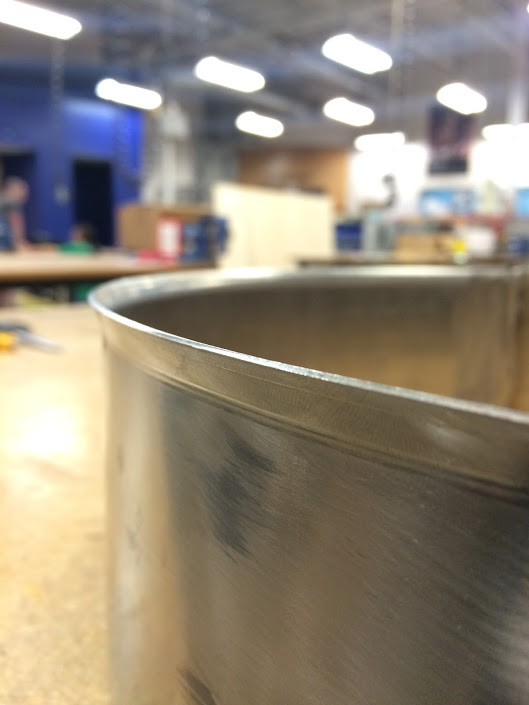

Small update. I'll be adding a 4.25" lip to the top of the kettle. A few reasons I've wanted to do this. Mainly having a recirculating mash strainer sitting right at the top of the kettle is a spill over waiting to happen. I've had to very gingerly stir the mash with 20+Lbs of grain as it sits right at the brim. This way if it does over flow it'll flow back into the kettle. The cross bars will hold the strainer basket when mashing and also at the top of the kettle while sparging, much like the Grainfather system.

Volume will also increase to 17.5 gallons which will be well used.

The lip will also allow me to use the lid from the Bayou kettle directly on this system.

Small update. I'll be adding a 4.25" lip to the top of the kettle. A few reasons I've wanted to do this. Mainly having a recirculating mash strainer sitting right at the top of the kettle is a spill over waiting to happen. I've had to very gingerly stir the mash with 20+Lbs of grain as it sits right at the brim. This way if it does over flow it'll flow back into the kettle. The cross bars will hold the strainer basket when mashing and also at the top of the kettle while sparging, much like the Grainfather system.

Volume will also increase to 17.5 gallons which will be well used.

The lip will also allow me to use the lid from the Bayou kettle directly on this system.

This is a thing of beauty. Quality professional build that puts mine to shame haha! I was wondering what the dimensions of the 44qt strainer basket are. I've been searching for one that will work in my 15.5gal recirc. Ebiab keggle. Keep up the awesome work!

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

This is a thing of beauty. Quality professional build that puts mine to shame haha! I was wondering what the dimensions of the 44qt strainer basket are. I've been searching for one that will work in my 15.5gal recirc. Ebiab keggle. Keep up the awesome work!

Thanks!

I'll measure it when I've got a moment. It sits about 2.5" off the kettle floor and along the inner bead of the Bayou kettle. If you're doing that large of brews I'd go for a larger basket, this one tops out ~25Lbs.

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

Hello!

Fabricated the lip last night. I increased the diameter a bit in order to use the bayou kettle as the grain basket and do higher gravity beers if wanted.

I started with some scrap 16g 304 I had. It was a bit shy on length so welded two bits together and smoothed out the welds. Popped it in the slip roll, welded it together and then into the bead roller for a flared lip. I'll get to welding it on next weekend. It'll be a lot of work (inside/outside welds) and then grinding and polishing.

Fabricated the lip last night. I increased the diameter a bit in order to use the bayou kettle as the grain basket and do higher gravity beers if wanted.

I started with some scrap 16g 304 I had. It was a bit shy on length so welded two bits together and smoothed out the welds. Popped it in the slip roll, welded it together and then into the bead roller for a flared lip. I'll get to welding it on next weekend. It'll be a lot of work (inside/outside welds) and then grinding and polishing.

Damn - good work. Helps to have access to a shop!!

DarkStormBrewing

Well-Known Member

This build is very cool.

OneManBrewery

Well-Known Member

Gets better and better. Do you have an estimated cost so far?

Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

Gets better and better. Do you have an estimated cost so far?

Roughly, a lot more than I'd intended I imagine haha.

BOM

Keg - $40

Pump - $150

TC Fittings - $275

SS Square Bar - $80

Wheels- $20

Bayou Strainer - $40

Control Panel - $60

CFC - $100

Man Hours - ...100+ probably.

So ~$750 I'd say. I just need to have ideas stop popping into my head so I can finish the damn thing!

wright530

Member

Love your build! Wish I had your metal working skills and equipment! I am doing a similar build and am trying to decide if I want two 120v elements or one 240v. Are you using two separate circuit 20 amp outlets or just regular 15 amp ones? I like the new 120v elements that come bent and with a Triclamp and L6-30 connector attached at Brewhardware, I am just worried that 2 1650 watt in 15 amp plugs might not be enough for the boil if I do 10 gallon batches. If you are using 15 amp plugs I think it will be ok. The extra up front cost will be worth the extra versatility if so...

I am just worried that 2 1650 watt in 15 amp plugs might not be enough for the boil if I do 10 gallon batches.

No need for concern. I use two 1500 watt elements and have easily boiled over 13 gallons, and didn't even use full power of both elements. I think I had one set at 70%.

scallopking

Well-Known Member

- Joined

- Sep 23, 2015

- Messages

- 198

- Reaction score

- 46

Just freaking awesome craftmanship, really nice work!!  I have a GF and I want one of these now.

I have a GF and I want one of these now.

I have a GF and I want one of these now.

I have a GF and I want one of these now.ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

C'mon, man! Show us some closeups of the new lip/collar! I'm guessing you just sealed the top and filled the whole keg with argon?

I've been wanting to do something like this and have just had too many other projects. Need to get back under the hood and brush up on my skills!

I've been wanting to do something like this and have just had too many other projects. Need to get back under the hood and brush up on my skills!

wright530

Member

No need for concern. I use two 1500 watt elements and have easily boiled over 13 gallons, and didn't even use full power of both elements. I think I had one set at 70%.

How are you controlling the two elements? With one PID or two? Does it matter where you plug them in ie: 20amp outlet vs. 15amp, outlets on seperate breakers etc.?

Similar threads

- Replies

- 0

- Views

- 379

- Replies

- 0

- Views

- 345

- Replies

- 1

- Views

- 674

- Replies

- 1

- Views

- 736

- Replies

- 11

- Views

- 688

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)