Hey everybody,

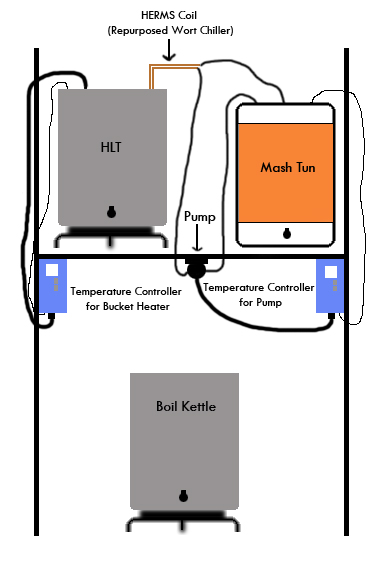

After taking some time off of brewing to handle some work responsibilities, it is time for me to get back into the brewing game. I have about a half dozen brews under my belt and I am ready to take the plunge and start building a HERMS system. Unfortunately, I do not know how to do any metalwork or electrical wiring, so I had to get a bit creative. As such, I wanted to attach my design for my system so that I could get some feedback from the more experienced brewmeisters.

My plan is to drill two holes into the top of my mash tun, feed some food grade silicone tubing into each of them and seal them. Then attach the tubing to a chugger pump to feed it through a repurposed wort chiller sitting in my HLT to act as my HERMS coil which will then pump it back into the mash tun. I want to do it this way so that I can avoid compacting the grain bed, thereby leading to stuck sparges. I will hook the pump up to a Johnson thermostat controller so that it can automatically maintain the mash temperature. Then, I will use a propane burner to bring the HLT up to temperature, then shut off the propane burner and maintain the temperature with an electric bucket water heater hooked up to another Johnson thermostat controller. Then, when I am ready to sparge, I will attach the pump to the valve on the bottom of my HLT and pump the water into my mash tun. What do you all think? Do you have any suggestions? Thanks!

After taking some time off of brewing to handle some work responsibilities, it is time for me to get back into the brewing game. I have about a half dozen brews under my belt and I am ready to take the plunge and start building a HERMS system. Unfortunately, I do not know how to do any metalwork or electrical wiring, so I had to get a bit creative. As such, I wanted to attach my design for my system so that I could get some feedback from the more experienced brewmeisters.

My plan is to drill two holes into the top of my mash tun, feed some food grade silicone tubing into each of them and seal them. Then attach the tubing to a chugger pump to feed it through a repurposed wort chiller sitting in my HLT to act as my HERMS coil which will then pump it back into the mash tun. I want to do it this way so that I can avoid compacting the grain bed, thereby leading to stuck sparges. I will hook the pump up to a Johnson thermostat controller so that it can automatically maintain the mash temperature. Then, I will use a propane burner to bring the HLT up to temperature, then shut off the propane burner and maintain the temperature with an electric bucket water heater hooked up to another Johnson thermostat controller. Then, when I am ready to sparge, I will attach the pump to the valve on the bottom of my HLT and pump the water into my mash tun. What do you all think? Do you have any suggestions? Thanks!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)