I'm kind of resurrecting a thread from long ago here. You can see it here: https://www.homebrewtalk.com/showthread.php?t=156921

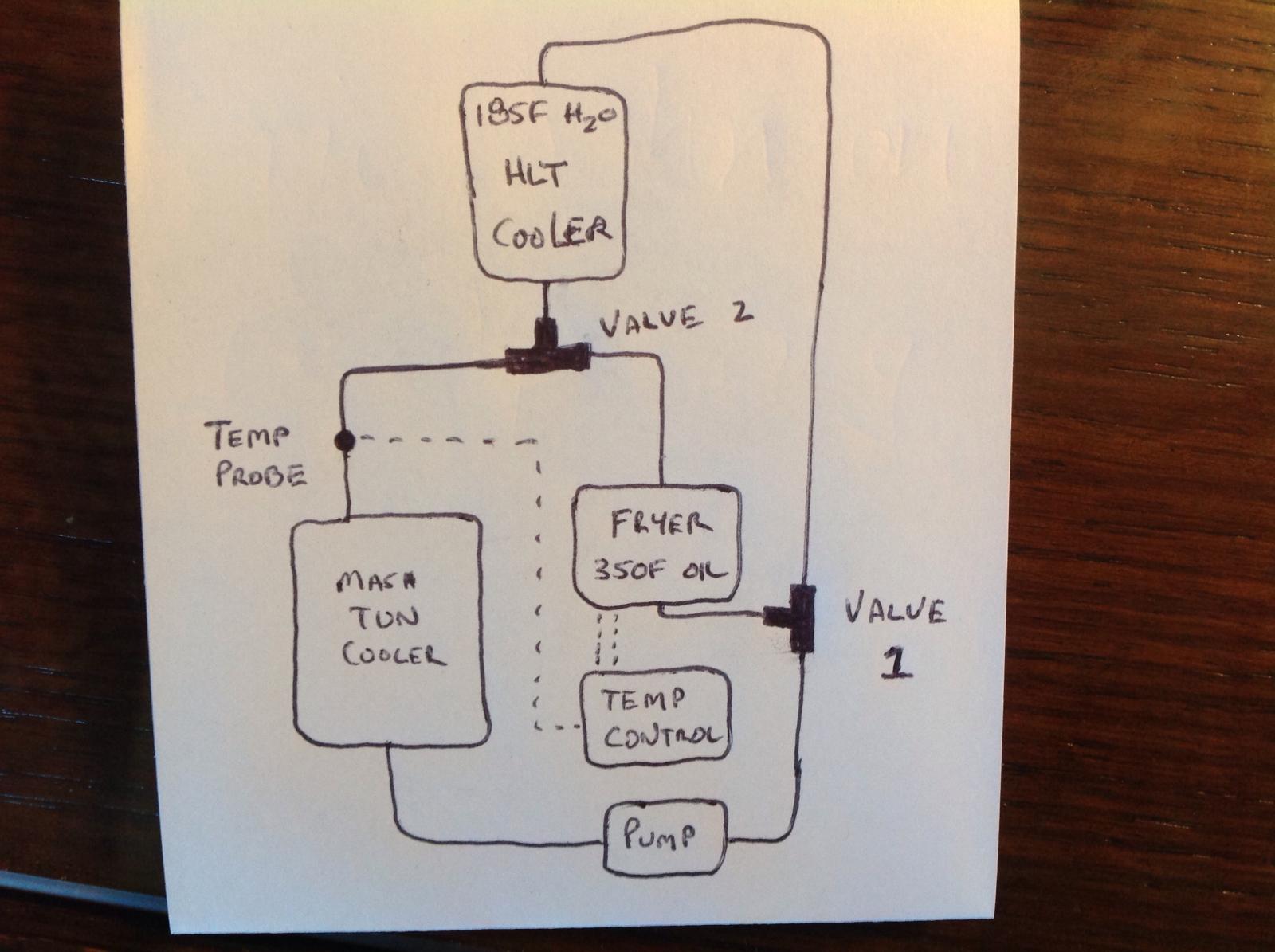

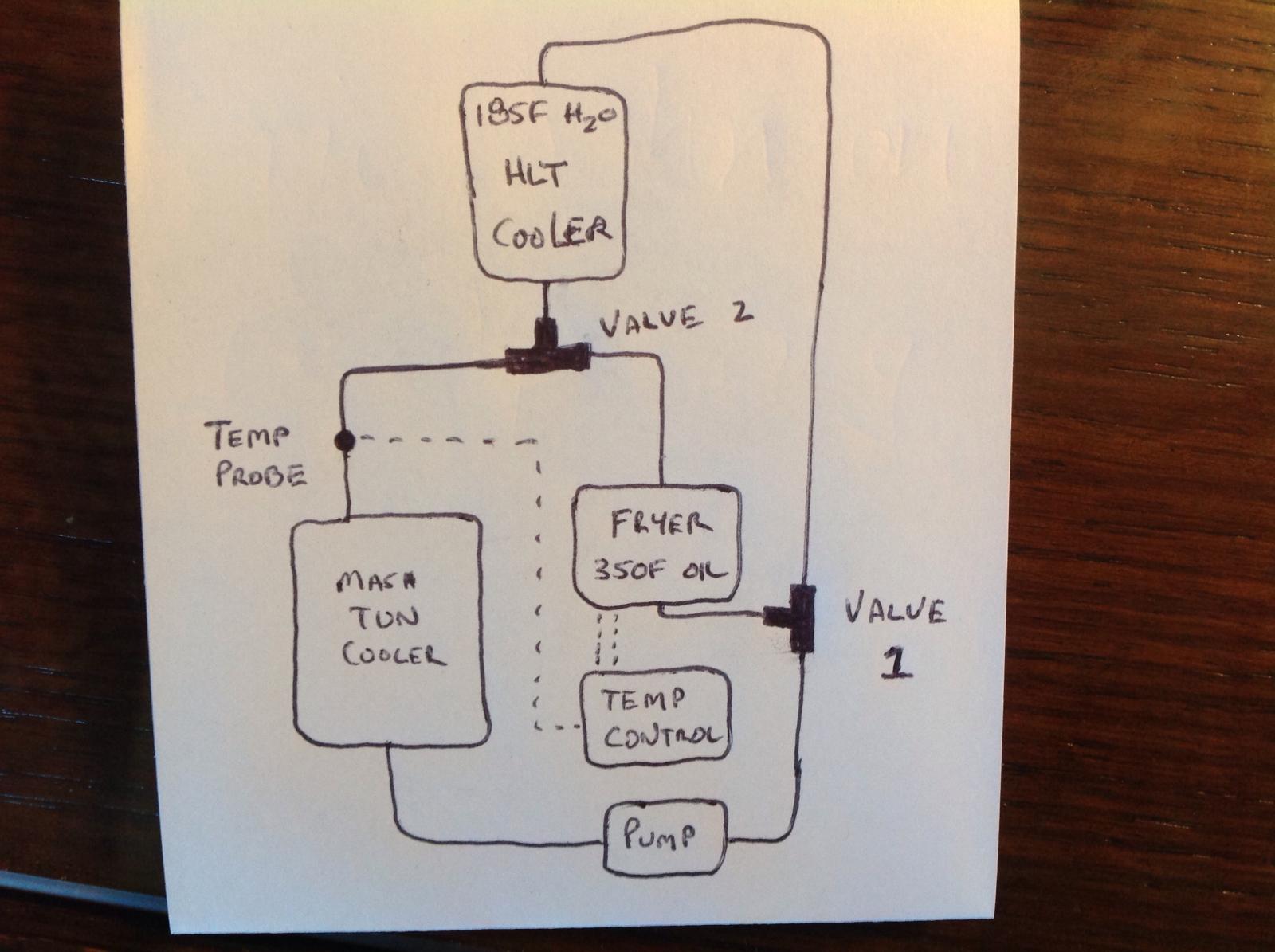

I'm toying with getting into HERMS using my old 5 gal cooler for a HLT/primary exchanger and a fryer for the secondary/step exchanger. The higher strike water volume in HLT would be good for mash temp maintenance, while the low volume, high temp oil in the fryer could be used to step up the temps for various rests and mash out. I'd put a selectable valve (1) downstream of the pump that I can choose which exchanger my wort passes through. Valve 2 is there in lieu of two check valves. I would not be heating my strike water at any point using this system.

My question is, those of you using a fryer and oil for an exchanger, is anyone stepping with it? What kind of times are you seeing to go from 150F to 170F? Bigger even, maybe from a 120F protein rest to 150F? I know the fryer can do oil temps around 350-400F, so what fryer temp are you using? Anything I'm missing? Thanks!

I'm toying with getting into HERMS using my old 5 gal cooler for a HLT/primary exchanger and a fryer for the secondary/step exchanger. The higher strike water volume in HLT would be good for mash temp maintenance, while the low volume, high temp oil in the fryer could be used to step up the temps for various rests and mash out. I'd put a selectable valve (1) downstream of the pump that I can choose which exchanger my wort passes through. Valve 2 is there in lieu of two check valves. I would not be heating my strike water at any point using this system.

My question is, those of you using a fryer and oil for an exchanger, is anyone stepping with it? What kind of times are you seeing to go from 150F to 170F? Bigger even, maybe from a 120F protein rest to 150F? I know the fryer can do oil temps around 350-400F, so what fryer temp are you using? Anything I'm missing? Thanks!