Thulsadoom

New Member

- Joined

- Feb 25, 2017

- Messages

- 1

- Reaction score

- 0

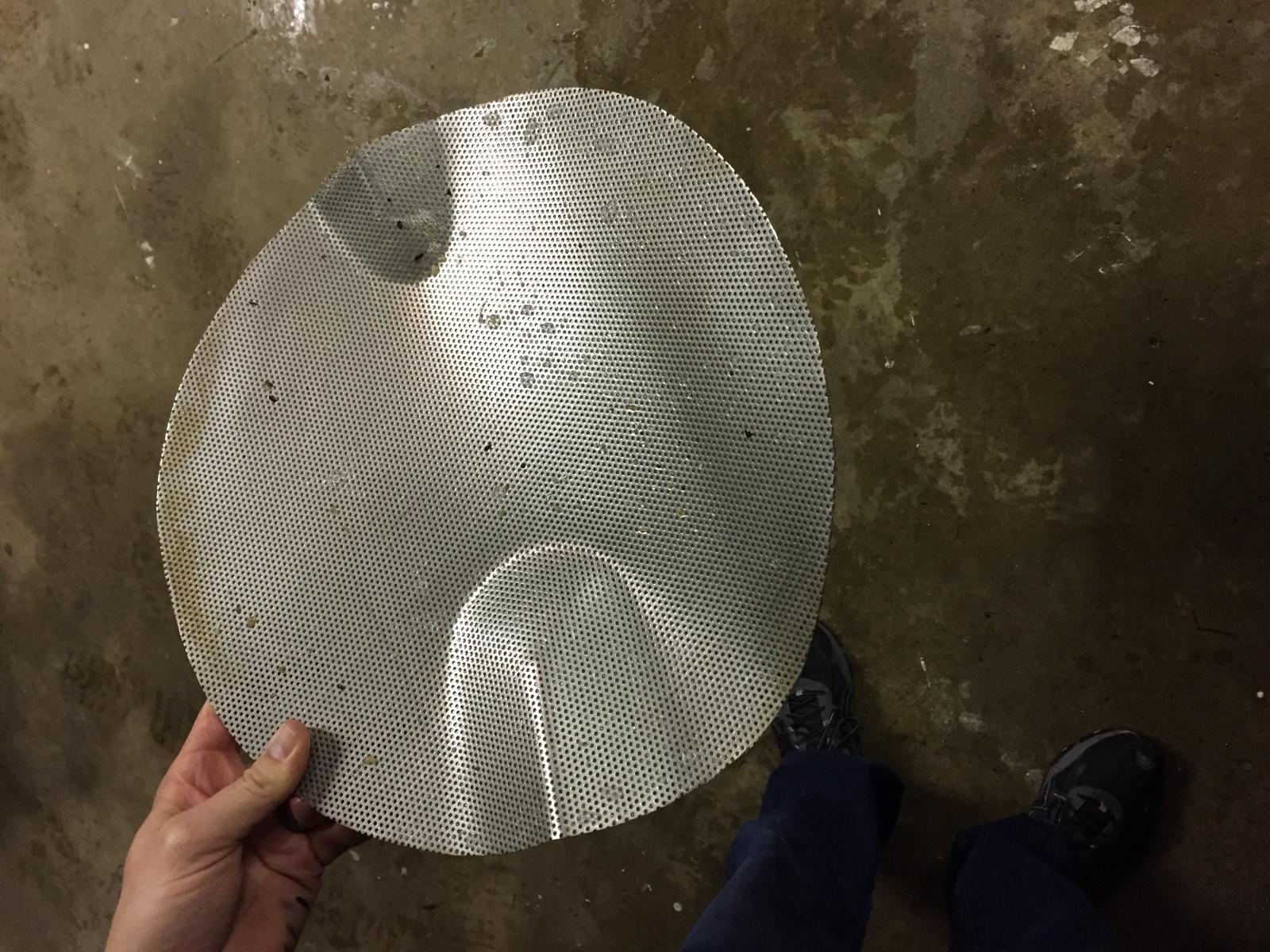

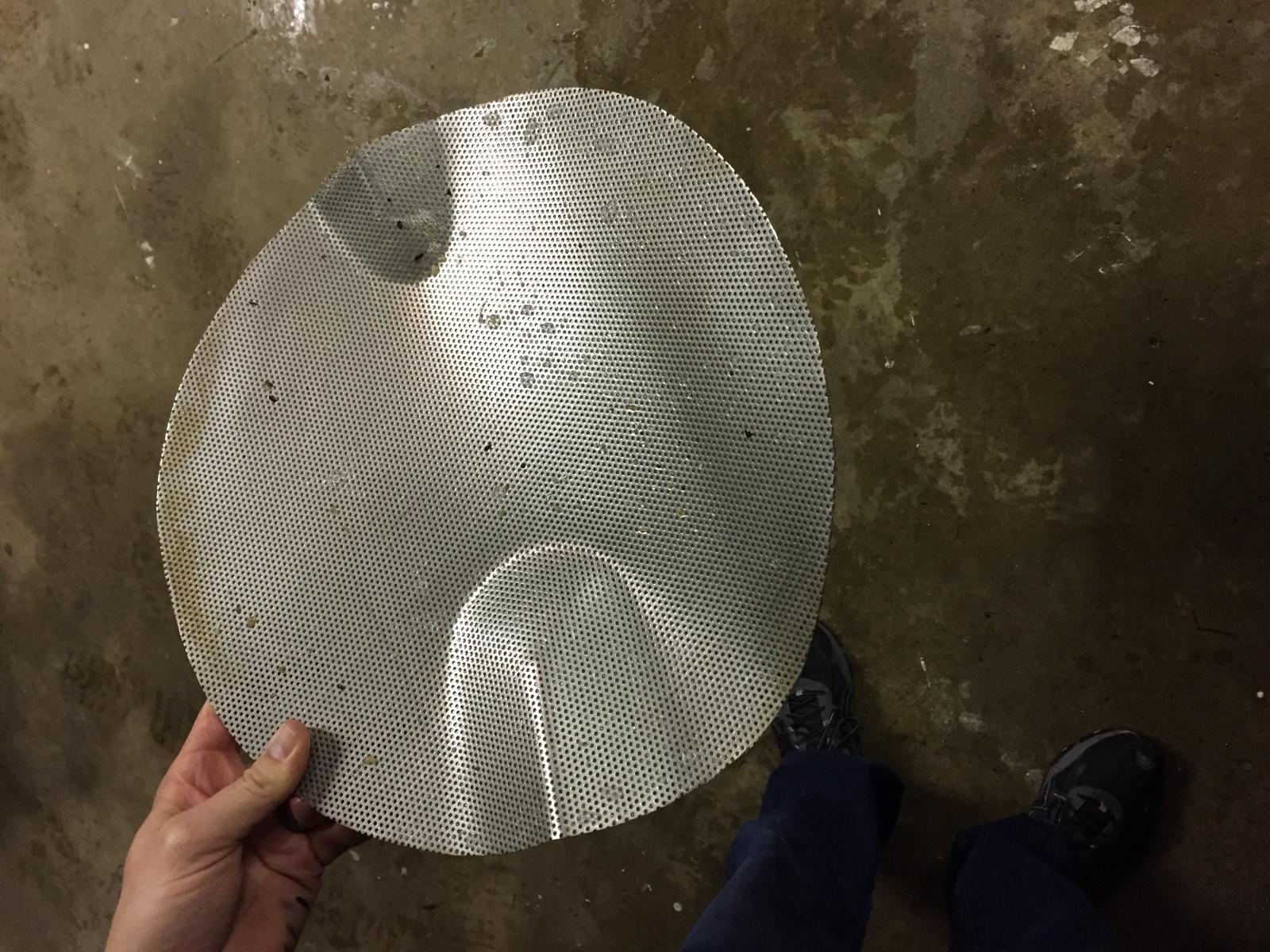

Inherited an all keg system with herms that's been used for years with out a hitch we decided to make a speedway clone which calls for 35 lbs of grain. Mash and Lauter clogged and grain getting drawn by pump. When done we found false bottom crushed and contoured around the intake. Don't know gauge of steel but this stuff seems pretty tough. I think the pressure is hugely multiplied because it's all applied to one small contact point of metal contact, not entire surface area. Either way it's for real