You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Critique my brewstand design please.

- Thread starter brewman !

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

fifelee

Well-Known Member

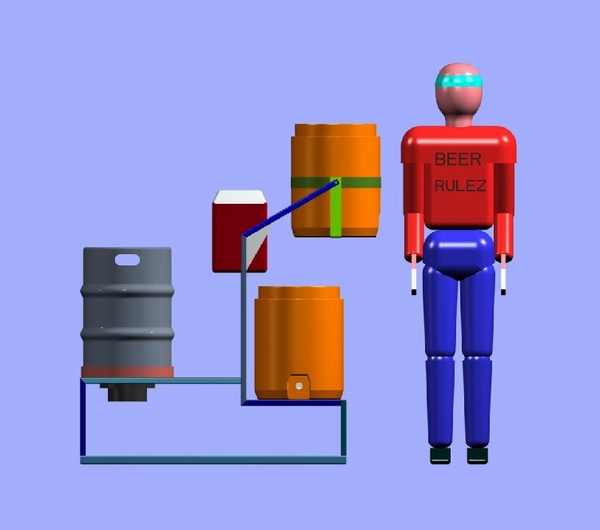

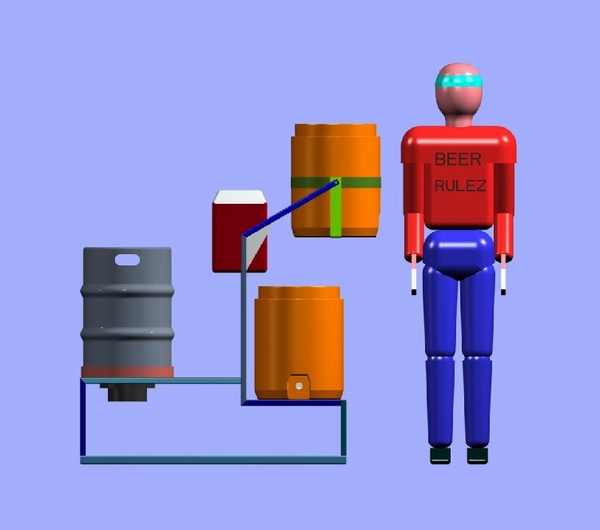

I thought I would try to minimize the frame. The brewer is 6' tall.

runhard: thanks for the info.

I thought the same thing about the frame after I drew it last night, fifelee.

I like how everything is getting simpler and simpler.

I think I am going to abandon the Gotts for the Cubes. The Cubes are 17 inches to a side. One problem with the cubes is that the lid opens the wrong way WRT the spigot. I might have to swap the whole lay out left to right.

Even with the Gotts, there is really no reason to make the system as low as I did. The top of your mash tank is about 5 feet. My layout is almost too low.

I thought the same thing about the frame after I drew it last night, fifelee.

I like how everything is getting simpler and simpler.

I think I am going to abandon the Gotts for the Cubes. The Cubes are 17 inches to a side. One problem with the cubes is that the lid opens the wrong way WRT the spigot. I might have to swap the whole lay out left to right.

Even with the Gotts, there is really no reason to make the system as low as I did. The top of your mash tank is about 5 feet. My layout is almost too low.

As far as the control system goes, I am trying to find a serial port (RS232) board that has a number of 8 or 10 bit analog to digital converters on it as well as a few digital outputs.

Something like this, but these prices are too high.

http://www.superlogics.com/serial-data-acquisition/rs-232-analog-input-systems/115.htm

The analog to digital converters can be use to read temperature via thermistors. I like thermistors over thermocouples because they are cheap, accurate and you don't need special wire or connectors or junction temp correction to use them. One would need 1 ADC channel for every temperature sensor. I plan to run about 6 temp sensors, but fewer would probably do. (Hot water tank, heater tank, 2 in the mash bed, 1 for circulating wort in and 1 for circulating wort out.)

The digital outs can be used to drive solid state relays to turn things on and off. I've only got 2 things thus far, the 2 heater elements. I might add the pump to that.

Why RS232 and not USB ? Well, I'll be programming the control application in Java so that its multi platform. (Windows, Mac and Linux). And I don't know of any Java USB drivers for Windows. But I know of a Java RS232 driver for Windows and Linux and it might even work for the Mac.

It would be nice to use an off the shelf board instead of a micro controller so that people don't have to program the microcontroller. I can do the analog to digital and digital IO very easily with a $55 microcontroller, but I'd have to teach you guys how to download a program to it. Which truthfully, isn't very hard.

Here is a great microcontroller that could do all this and a whole lot more !

http://www.technologicalarts.ca/catalog/product_info.php/cPath/50_69/products_id/311

It has an Ethernet interface, so it could be connected to the Internet via a router or you could just connect it to your laptop with an ethernet cable. Imagine being able to watch your mash progress from from a browser at work !

If your brewing room happens to have an Ethernet jack and you have a wireless router, you could plug the brew controller into your network and then take your laptop with you around the house and watch the mash progress while playing with your kids, having dinner with your wife, etc. I don't have an Ethernet jack in my garage, but I think I'd put one in for this purpose.

One could add a few sensors like maybe a mash bed level switch or a recirc flow sensor too.

Are you guys interested in this or am I building this for myself ? One can buy simple setpoint controllers for $65 each to run the heater elements if you want something easier. It is very easy to download a program to a microcontroller...

In case you haven't figured out, I brew some beers with long mash schedules. 30 minutes at 127F and then 2 hours at 15XF. I'd love to be able to program my brew stand to have the hot water up to temp at 6AM, get up and dough in the mash, set up recirc and... go back to sleep for a few hours ! Get up at 9AM with everything at mash out temps, ready to mash out and start the boil. That would be so neat. One could start a second batch while watching the boil on the first batch. Oh, and they would be 10 gallon batches, going straight into my Sanke keg fermentors. That would be heaven ! 20 gallons of high quality brew without breaking a sweat or wasting the entire day. Not that a brewing day is ever wasted.

My father in law is a beer drinker and lives out of town. He loved some of my beers back when I was brewing. We are always bored when he visits. If I had this setup he could bring a couple carboys and we could brew a couple 12 gallon batches and split them. That would be so neat, especially for him. He loves making kit wines, but would never build a brewing rig. He'd love to ferment his own brews.

Something like this, but these prices are too high.

http://www.superlogics.com/serial-data-acquisition/rs-232-analog-input-systems/115.htm

The analog to digital converters can be use to read temperature via thermistors. I like thermistors over thermocouples because they are cheap, accurate and you don't need special wire or connectors or junction temp correction to use them. One would need 1 ADC channel for every temperature sensor. I plan to run about 6 temp sensors, but fewer would probably do. (Hot water tank, heater tank, 2 in the mash bed, 1 for circulating wort in and 1 for circulating wort out.)

The digital outs can be used to drive solid state relays to turn things on and off. I've only got 2 things thus far, the 2 heater elements. I might add the pump to that.

Why RS232 and not USB ? Well, I'll be programming the control application in Java so that its multi platform. (Windows, Mac and Linux). And I don't know of any Java USB drivers for Windows. But I know of a Java RS232 driver for Windows and Linux and it might even work for the Mac.

It would be nice to use an off the shelf board instead of a micro controller so that people don't have to program the microcontroller. I can do the analog to digital and digital IO very easily with a $55 microcontroller, but I'd have to teach you guys how to download a program to it. Which truthfully, isn't very hard.

Here is a great microcontroller that could do all this and a whole lot more !

http://www.technologicalarts.ca/catalog/product_info.php/cPath/50_69/products_id/311

It has an Ethernet interface, so it could be connected to the Internet via a router or you could just connect it to your laptop with an ethernet cable. Imagine being able to watch your mash progress from from a browser at work !

If your brewing room happens to have an Ethernet jack and you have a wireless router, you could plug the brew controller into your network and then take your laptop with you around the house and watch the mash progress while playing with your kids, having dinner with your wife, etc. I don't have an Ethernet jack in my garage, but I think I'd put one in for this purpose.

One could add a few sensors like maybe a mash bed level switch or a recirc flow sensor too.

Are you guys interested in this or am I building this for myself ? One can buy simple setpoint controllers for $65 each to run the heater elements if you want something easier. It is very easy to download a program to a microcontroller...

In case you haven't figured out, I brew some beers with long mash schedules. 30 minutes at 127F and then 2 hours at 15XF. I'd love to be able to program my brew stand to have the hot water up to temp at 6AM, get up and dough in the mash, set up recirc and... go back to sleep for a few hours ! Get up at 9AM with everything at mash out temps, ready to mash out and start the boil. That would be so neat. One could start a second batch while watching the boil on the first batch. Oh, and they would be 10 gallon batches, going straight into my Sanke keg fermentors. That would be heaven ! 20 gallons of high quality brew without breaking a sweat or wasting the entire day. Not that a brewing day is ever wasted.

My father in law is a beer drinker and lives out of town. He loved some of my beers back when I was brewing. We are always bored when he visits. If I had this setup he could bring a couple carboys and we could brew a couple 12 gallon batches and split them. That would be so neat, especially for him. He loves making kit wines, but would never build a brewing rig. He'd love to ferment his own brews.

You're using an old lappy to control this thing, right?

Not sure why you need to go from the board but...

http://www.gridconnect.com/ltrx.html

By why not use exisitng serial port?

http://www.gridconnect.com/net232-dte.html

or

http://www.gridconnect.com/wi232.html with Wi-Fi

Not sure why you need to go from the board but...

http://www.gridconnect.com/ltrx.html

By why not use exisitng serial port?

http://www.gridconnect.com/net232-dte.html

or

http://www.gridconnect.com/wi232.html with Wi-Fi

You're using an old lappy to control this thing, right?

No, not an old one. A modern one. It has USB, WIFI, etc. I am working on it right now.

Not sure why you need to go from the board but...

http://www.gridconnect.com/ltrx.html

By why not use exisitng serial port?

http://www.gridconnect.com/net232-dte.html

or

http://www.gridconnect.com/wi232.html with Wi-Fi

The Internet connection is optional. We need a connection from the computer to the controller. It could be RS232 because most computers have RS232 ports or you can get a USB RS232 device. It could be an Ethernet connection if one used the microcontroller that I showed.

If one needed a wireless Ethernet connection to the brewstand, one could buy a regular wireless router and plug the controller with Ethernet into it. Most wireless routers can be meshed together to form a wider network. Wireless routers are pretty inexpensive these days. $50. That isn't a bad idea, actually.

The only problem is that one might get distracted surfing beer porn while brewing ! Add a few USB cameras and one could have brew cam going with live brew data. Hmmm... I'm just thinking off the top of my head here... some of this is going beyond the bounds of traditional brewing. Is that a bad thing ?

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

fifelee

Well-Known Member

More random ideas.

Yeah, fifelee, that is beautiful.

I'd be concerned with how you are going to lock that tipping mash tun though. That sucker will be heavy.

I'd be concerned with how you are going to lock that tipping mash tun though. That sucker will be heavy.

I'd be concerned with how you are going to lock that tipping mash tun though. That sucker will be heavy.

Hold it in the tipped position or hold it in the brew position ?

There are a number of ways to do that. One could make the pivot from a shaft and have it rotate inside a sleeve and then put a pin through both of them. Did I mention I have a CNC lathe and a mill ?

I was thinking of putting a long retractable pull arm on the pivot too, so that dumping and holding the mash vessel is easy.

I don't like the bottom level being filled in. Any drips there make a mess. I would rather they drip onto the floor. Just a preference thing. The wheels look like lawn mower wheels. Give me a bad vibe. Maybe I'm insecure.

There should be an arm going up to the top of the mash vessel, maybe a hard pipe so that there is a feed to the sparge manifold and so the hose isn't just hanging down.

I wanted the heat shield to be a straight way so that one could hang hoses and stirring spoons and things like that. I never seem to have a place to put that stuff. Maybe a nice SS drip tray under them ?

And we need a place to put the lid for the kettle when its off ! Mine always ends up on the floor. Nothing like a little dirt in one's brew.

The drain and valve for the mash vessel will come straight off the bottom. I want the stock drain valve to take wort samples as I am mashing and also for easy draining after its washed out.

I should tell you guys what I do with the hot water from my CFC ! I push it into the HLT and Mash Vessel and use it for cleaning. And when I am done with it then, I water my lawn or garden.

I really like how this is coming together. Any more suggestions ? Its all in the details. I want to hear more ideas if you have them.

fifelee: could you generate it with a few color changes ? Make the frame all black. Open up the bottom. Make the green straps holding the mash vessel really silver like SS would be. Make the heat shield SS too. And make the brewpot lighter. Make the center of the wheels black. Thanks

I wonder if the cubes need to sit on a flat surface that totally covers the underside of them ? Maybe they will warp if they don't ? (Stressed inner and outer plastic skins ?)

brewman ! said:As far as the control system goes, I am trying to find a serial port (RS232) board that has a number of 8 or 10 bit analog to digital converters on it as well as a few digital outputs.

Arduino

This board is sweet!! It only has 6 analog controls, and 14 digital, but if you search their site some people have made multiplexors for it. It also has java lib for it too and usb connection!!

Ohh and its cheap! $32.00

Check it out

http://www.sparkfun.com/commerce/product_info.php?products_id=666

Theres another one out there but i cant remember what its call but its all based on the wiring lanaguage.

Excellent find on the IO board ! I'm game to use it. I'm a Linux guy/developer, so its perfect for me and it supports all platforms and java to boot. Perfect.

Question: is this project just for me or are others thinking of building one ? It should be pretty inexpensive.

Some costs... pump, new, $50, controller board $32, solid state relays for switching 250VAC, 20A, $34 each, 4.5KW heating elements, $10 each. Cubes are $15 each if you find them on sale. The HERM heater vessel needs a copper coil in it. About 15 feet of 1/2" or 25 feet of 3/8" if my calcs are right. Fittings. Quick connects. Paint.

I assume you all have a brew pot and a computer and a burner and you can rig up a false bottom for the mash vessel. Likewise you probably have chillers.

Wheels are optional.

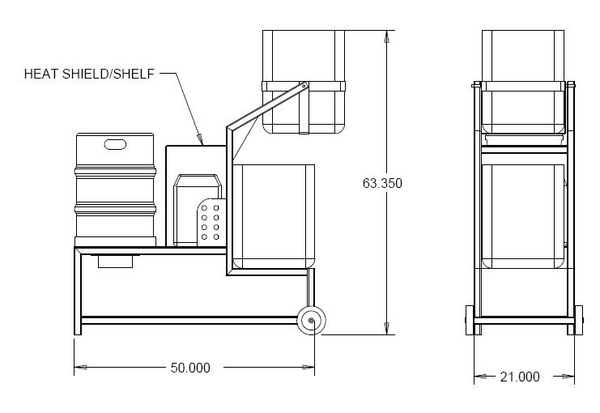

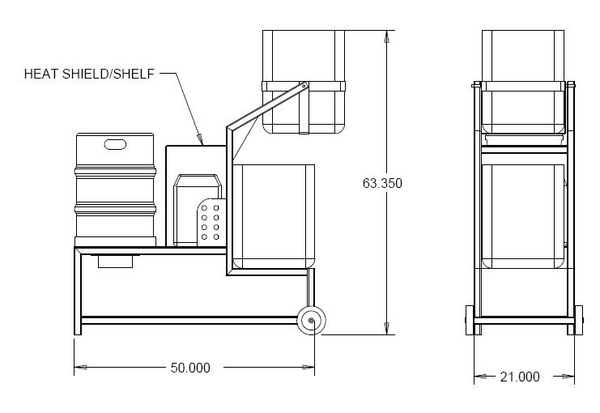

I think the steel is down to about 30 feet now, 1.5" or 2" square tubing. I'd probably go for 0.125 wall now and get rid of the gusset in the angle bend there. The mash vessel holds 12 gallons x 8.5 pounds per gallon = 100ish pounds. Its center is about 2 feet from the arm's attachment point on the frame, so that is 200 ftlbs of torque and there are 2 arms, so 100 ftlbs of torque each. No problem for a decent weld with 0.125 or even 0.100 wall. Maybe 0.100 wall with 2x2 material.

Is this interesting to other people or just me ?

Question: is this project just for me or are others thinking of building one ? It should be pretty inexpensive.

Some costs... pump, new, $50, controller board $32, solid state relays for switching 250VAC, 20A, $34 each, 4.5KW heating elements, $10 each. Cubes are $15 each if you find them on sale. The HERM heater vessel needs a copper coil in it. About 15 feet of 1/2" or 25 feet of 3/8" if my calcs are right. Fittings. Quick connects. Paint.

I assume you all have a brew pot and a computer and a burner and you can rig up a false bottom for the mash vessel. Likewise you probably have chillers.

Wheels are optional.

I think the steel is down to about 30 feet now, 1.5" or 2" square tubing. I'd probably go for 0.125 wall now and get rid of the gusset in the angle bend there. The mash vessel holds 12 gallons x 8.5 pounds per gallon = 100ish pounds. Its center is about 2 feet from the arm's attachment point on the frame, so that is 200 ftlbs of torque and there are 2 arms, so 100 ftlbs of torque each. No problem for a decent weld with 0.125 or even 0.100 wall. Maybe 0.100 wall with 2x2 material.

Is this interesting to other people or just me ?

I'd love to but I think the controller thing is a little outa my skill base.

I'd love to but I think the controller thing is a little outa my skill base.

I could teach a 6 year old to upload code to the controller.

I'll write a Java app that runs on the PCs. That will be the user interface to the brewing process. It will have a temperature chart, a mash temp schedule, etc. I'll make it open source so that anyone that wants the code to make changes or improve it can. And those that just want to use it can.

And I'll write the controller code as well. Same thing, share it, etc.

All a non computer user would have to do is install the Java app on their PC and then download the code onto the board. As a matter of fact, we could make the download process part of the Java app, so it happens automatically.

I do this sort of stuff all the time.

Once the code is loaded on the controller, you'll just have to wire it up. That is pretty straight forward. Not really much different from those Love controllers. But this will do tons and tons more things.

Sounds good.

A bit more advanced than this,

A bit more advanced than this,

A bit more advanced than this,

There is nothing wrong with "that". I brewed in the kitchen too. I'm not criticizing anyone for brewing like "that".

I'm just at a point where I want a nice brew rig. Something I park in the garage and forget until I need it.

And when I need it, I want to roll it out, plug it in and go to work. I don't want to mess up the kitchen. I don't smell up the house. I'll make 6 or 12 gallons of high quality wort. It doesn't take all day. I'm not totally wore out from brewing 5 or 10 gallons. I don't have to intensively babysit it until I have to watch for boil overs. That is what I want.

Its a time thing.

And its also the quality of the beer I can brew. My beers got better with my HERMs setup, but I bet they will be much better with this rig. Mashing is all about temperature control and this rig should do that in spades. And then, when the batch is done, we should be able to save the temperature profile of the mash and analyze it 45 days later when we drink the beer. It should give repeatable results, time after time.

I agree about making the frame open for easier cleaning etc.

I think any of the thin sheet steel would need to be in stainless. The frame looks functional. I'd be worried about those wheels. I think I'd prefer them to be on 4 legs and us a load carrier/jack to move it.

like this but the industrial sturdy version.

http://www.comparestoreprices.co.uk/tool-kits/clarke-load-carrier.asp

I think any of the thin sheet steel would need to be in stainless. The frame looks functional. I'd be worried about those wheels. I think I'd prefer them to be on 4 legs and us a load carrier/jack to move it.

like this but the industrial sturdy version.

http://www.comparestoreprices.co.uk/tool-kits/clarke-load-carrier.asp

Here are some interesting posts from the more beer forum, where they discuss the B3-1550, etc.

Here is a discussion of RIMS and HERMS. I don't agree with everything that is said here.

http://morebeer.com/phpBB2/viewtopic.php?t=15454

Here is a nice single tier system. He went totally electric. I can't help but think that its no longer necessary to use SS for the HLT or MLT anymore. And my last HLT was SS ! Notice the use of 2 pumps. My last system was 1 tier. I got away with using 1 pump by using it to pump wort into the boiler and manually rinsing the bed with a pitcher of water from the HLT. It worked, I guess. It wasn't the nice smooth flow that a pump would give. I'll be using a float control on my next rig.

http://morebeer.com/phpBB2/viewtopic.php?t=12909

Does a 1550 save time ?

http://morebeer.com/phpBB2/viewtopic.php?t=15282

One guy did an AG brew in 4 hours !

Notice in his estimate the first 30 minutes of that was warming sparge water. I want the computer to have my sparge water at mash in temp when I enter the garage in the morning. No waiting.

I want the mash to proceed without me adjusting any temps, even if its a multi step mash. I'll check circulation from time to time. I want the sparge to be mostly automatic too.

I understand I'll have to watch the boil. No problem. BTW: the PC software should beep when its time to put the hops in so they aren't forgotten.

Another guy has the HLT at the right temp when he is done his morning coffee.

"I opted for the plain SMART and the digital HLT. I run the smart continuously with the HLT set at 10 deg higher then I want my mash. this work very good. While it is mashing, I can sit and read."

Just for giggles, the digital SMART option is $385, the deluxe control panel is $445, the sparge pump level control option is $90 and the digital hot liquor control option is $450. I'll spend a ton less on my whole rig than what those options cost ($1370) and it will do a lot more. For instance, we could add another solid state relay to the setup and turn the coffee pot on at 7:30AM !

http://morebeer.com/browse.html?category_id=1129&keyword=&x=1&y=1

Here is a discussion of RIMS and HERMS. I don't agree with everything that is said here.

http://morebeer.com/phpBB2/viewtopic.php?t=15454

Here is a nice single tier system. He went totally electric. I can't help but think that its no longer necessary to use SS for the HLT or MLT anymore. And my last HLT was SS ! Notice the use of 2 pumps. My last system was 1 tier. I got away with using 1 pump by using it to pump wort into the boiler and manually rinsing the bed with a pitcher of water from the HLT. It worked, I guess. It wasn't the nice smooth flow that a pump would give. I'll be using a float control on my next rig.

http://morebeer.com/phpBB2/viewtopic.php?t=12909

Does a 1550 save time ?

http://morebeer.com/phpBB2/viewtopic.php?t=15282

One guy did an AG brew in 4 hours !

Notice in his estimate the first 30 minutes of that was warming sparge water. I want the computer to have my sparge water at mash in temp when I enter the garage in the morning. No waiting.

I want the mash to proceed without me adjusting any temps, even if its a multi step mash. I'll check circulation from time to time. I want the sparge to be mostly automatic too.

I understand I'll have to watch the boil. No problem. BTW: the PC software should beep when its time to put the hops in so they aren't forgotten.

Another guy has the HLT at the right temp when he is done his morning coffee.

"I opted for the plain SMART and the digital HLT. I run the smart continuously with the HLT set at 10 deg higher then I want my mash. this work very good. While it is mashing, I can sit and read."

Just for giggles, the digital SMART option is $385, the deluxe control panel is $445, the sparge pump level control option is $90 and the digital hot liquor control option is $450. I'll spend a ton less on my whole rig than what those options cost ($1370) and it will do a lot more. For instance, we could add another solid state relay to the setup and turn the coffee pot on at 7:30AM !

http://morebeer.com/browse.html?category_id=1129&keyword=&x=1&y=1

I think I'd prefer them to be on 4 legs and us a load carrier/jack to move it.

I guess that is the nice thing about building it yourself - we can each make it the way we want.

We have some big tables at work that ride on 4 inch casters. If my rig was always going to be on a smooth surface, I'd use those.

If it is going off road, then I'd like 2 big pneumatic wheels on one end and wheel barrow handles on the other end. Something like this.

http://yematyre.en.alibaba.com/prod...er_wheel_pneumatic_wheel/wheel_with_tire.html

At first I thought that was overkill, but I can just see rolling this thing out on the lawn some day and running off a batch while the kids play outside and maybe my wife suntans. We can all dream, right ? My 220V extension cord is 25 feet long and the plug is at the back of the garage. Cord through the window, I'm there !

Now, I bet there is some spillage in that scenario and grass gets soft when wet. Casters would be useless then. Next problem would be a fly landing in the fermentor just as it gets filled !

Doing it manually.

First thing I do is rehydrate my yeast,]

Then put the mash water on.

While this is waiting I set the mash tun up and weigh the grain bill.

The waters done and I then do the mash for 90 minutes.

In the mean time I set up my kettle and get my sparge water ready

Time so far 2hrs.

My batch sparge take 20-30 minute.

Time 2hrs 30

Bring to the Boil 30 minutes

60 minute boil.

In the mean time clean the kitchen area rinse the mash tun and put away. Sanitise the Carboy and put the HLT away.

Time so far 4hrs

Chill the wort 25m

Aerate rack and pitch 20 mins

Time in total including set up, full brew and put away <5hrs

Even with automation I'd say it's hard to get below that with out cutting down the mash time. If you cut out the time to heat the mash water then you'd still need the time to prep for the brew.

I think you should rig a full espresso/latte machine up to it!

First thing I do is rehydrate my yeast,]

Then put the mash water on.

While this is waiting I set the mash tun up and weigh the grain bill.

The waters done and I then do the mash for 90 minutes.

In the mean time I set up my kettle and get my sparge water ready

Time so far 2hrs.

My batch sparge take 20-30 minute.

Time 2hrs 30

Bring to the Boil 30 minutes

60 minute boil.

In the mean time clean the kitchen area rinse the mash tun and put away. Sanitise the Carboy and put the HLT away.

Time so far 4hrs

Chill the wort 25m

Aerate rack and pitch 20 mins

Time in total including set up, full brew and put away <5hrs

Even with automation I'd say it's hard to get below that with out cutting down the mash time. If you cut out the time to heat the mash water then you'd still need the time to prep for the brew.

I think you should rig a full espresso/latte machine up to it!

I guess its not only how much time it takes overall, but how much attention it needs in that time. I agree that 4 to 5 hours is minimum. Could I possibly dough in and go have breakfast with my family ? That would be huge.

The other possibility is double batch brew days. Be mashing the second beer while boiling the first. Multi tasking !

Here is my latest iteration. I left the cubes low so that the mash can be stirred. A guy on another site made a good point about it being a pain to get at a high mash vessel. Someday I might want to batch sparge and that might require some stirring.

http://www.pbase.com/me2001/image/71677402

I hope I didn't sound too bossy about the gussets. They could be put in.

How low/high does one want the brew pot ? Keep in mind we have a pump to pump the wort through the chiller and into a fermentor.

The other possibility is double batch brew days. Be mashing the second beer while boiling the first. Multi tasking !

Here is my latest iteration. I left the cubes low so that the mash can be stirred. A guy on another site made a good point about it being a pain to get at a high mash vessel. Someday I might want to batch sparge and that might require some stirring.

http://www.pbase.com/me2001/image/71677402

I hope I didn't sound too bossy about the gussets. They could be put in.

How low/high does one want the brew pot ? Keep in mind we have a pump to pump the wort through the chiller and into a fermentor.

Something else happened here. We got the material required down far enough that we can start looking at something other than mild steel.

For example, one could use 2" x 2" aluminum, .125 wall. Its under $4 a foot, probably closer to $3 in 20 foot lengths. The only problem is that its much harder to weld. Time to start bolting this together ? I hate bolted frames !

http://www.onlinemetalsupply.com/st...il.aspx?sid=1&sfid=96027&c=696861&i=193260916

Its corrosion resistant (except for aluminum oxide) and shines up really nice.

The only part of the frame that I wouldn't make from aluminum is the kettle support pieces because it doesn't take a lot of heat to soften aluminum.

For example, one could use 2" x 2" aluminum, .125 wall. Its under $4 a foot, probably closer to $3 in 20 foot lengths. The only problem is that its much harder to weld. Time to start bolting this together ? I hate bolted frames !

http://www.onlinemetalsupply.com/st...il.aspx?sid=1&sfid=96027&c=696861&i=193260916

Its corrosion resistant (except for aluminum oxide) and shines up really nice.

The only part of the frame that I wouldn't make from aluminum is the kettle support pieces because it doesn't take a lot of heat to soften aluminum.

One more thing. My pump is self priming, so it could be moved up.

This whole brew rig is now so low now it might be unhandy. The pump and HLT are practically on the floor. I'd have to make sure there are no valves or connectors sticking out to trip over or catch an ankle on or break off. Might need a rail to protect things down there ? Or has it gotten too low ?

I think I'd move the pump right up underneath the hot water vessel and put the chiller at the bottom. But I'm not sure I'd like the control panel under the pump, getting wet every time the pump is uncoupled.

How about this ?

http://www.pbase.com/me2001/image/71678850

Now I've got this feeling that I'd like to move everything up about a foot, except the brew kettle.

Maybe like this ?

http://www.pbase.com/me2001/image/71679073

This whole brew rig is now so low now it might be unhandy. The pump and HLT are practically on the floor. I'd have to make sure there are no valves or connectors sticking out to trip over or catch an ankle on or break off. Might need a rail to protect things down there ? Or has it gotten too low ?

I think I'd move the pump right up underneath the hot water vessel and put the chiller at the bottom. But I'm not sure I'd like the control panel under the pump, getting wet every time the pump is uncoupled.

How about this ?

http://www.pbase.com/me2001/image/71678850

Now I've got this feeling that I'd like to move everything up about a foot, except the brew kettle.

Maybe like this ?

http://www.pbase.com/me2001/image/71679073

Here is a bunch of shots of a 1550 in action. Note the last images and then a series of quick shots showing how they dump the spent grains.

http://www.nhbrewers.com/mdf/brew/index.htm

Question: why am I not building my system with 2 or 3 of the cut off kegs I have ? They hold about 14 gallons each. Am I gaining anything by using coolers ? Less heat loss, I guess a lot less, which is important if one is using electric heat sources. But I could also insulate my kegs with hot water heater blankets pretty easily.

http://www.nhbrewers.com/mdf/brew/index.htm

Question: why am I not building my system with 2 or 3 of the cut off kegs I have ? They hold about 14 gallons each. Am I gaining anything by using coolers ? Less heat loss, I guess a lot less, which is important if one is using electric heat sources. But I could also insulate my kegs with hot water heater blankets pretty easily.

Brewman

I really like your idea of using your laptop and RS232 I am very interested in how I can do that. I am an industrial electrician and was going to use a micro logics processer with a panelview. But your way sounds A WHOLE BUNCH CHEAPER. I have never programed in JAVA is it much different than latter logic??? and what type of processing system do I need? In JAVA is there timers and such that you can program like you can with an allen bradley or GE latter logic functions. although I would like to learn a new way to program and if this way that your talking about can be done witha 50 doller processer and some relays I AM THERE I was going to use therrmel cuppels but thermisters are cheep and very accurate. So I would be happy to share with you some of ideas I have for automation on a brew system. I have found some float switches that can handle up to 180 deg F they are tank switches from mC Master carr by using two of these in your system you can basicly walk away during the sparge system I am using 120v AC solinoid valves and a magnitic drive pump to control flow. But my system is totally different from most, its an interesting set up with the hot h2o tank (electric 2 3000 watt elements @ 240 vac = 25 amps) (any dryer curcut in any garage can handle that ) sitting above the mash tun ( tippy tun) and boil kettel that are on the same plane and they are above the hop back/grant, and everything flows to and from the grant via a pump simple yet affective (I think) I am building it as we speak. anyhow temp control would be nice not having to buy a controler and I have to buy relays for the hot h2o tank anyway. how hard is it to make on the fly changes to this system your talking about???

Cheers

JJ

I really like your idea of using your laptop and RS232 I am very interested in how I can do that. I am an industrial electrician and was going to use a micro logics processer with a panelview. But your way sounds A WHOLE BUNCH CHEAPER. I have never programed in JAVA is it much different than latter logic??? and what type of processing system do I need? In JAVA is there timers and such that you can program like you can with an allen bradley or GE latter logic functions. although I would like to learn a new way to program and if this way that your talking about can be done witha 50 doller processer and some relays I AM THERE I was going to use therrmel cuppels but thermisters are cheep and very accurate. So I would be happy to share with you some of ideas I have for automation on a brew system. I have found some float switches that can handle up to 180 deg F they are tank switches from mC Master carr by using two of these in your system you can basicly walk away during the sparge system I am using 120v AC solinoid valves and a magnitic drive pump to control flow. But my system is totally different from most, its an interesting set up with the hot h2o tank (electric 2 3000 watt elements @ 240 vac = 25 amps) (any dryer curcut in any garage can handle that ) sitting above the mash tun ( tippy tun) and boil kettel that are on the same plane and they are above the hop back/grant, and everything flows to and from the grant via a pump simple yet affective (I think) I am building it as we speak. anyhow temp control would be nice not having to buy a controler and I have to buy relays for the hot h2o tank anyway. how hard is it to make on the fly changes to this system your talking about???

Cheers

JJ

Brewman I really like your idea of using your laptop and RS232

Thanks.

I am very interested in how I can do that. I am an industrial electrician and was going to use a micro logics processer with a panelview. But your way sounds A WHOLE BUNCH CHEAPER.

It is !

I have never programed in JAVA is it much different than latter logic???

You mean ladder logic, right ? Totally different. Night and day. Have you ever programmed in BASIC, Pascal, C or Fortran ? Its kind of like that. Its a language.

The board that was suggested has been set up especially for non programmers can use it. Check out the Arduino links above. There is lots there to read if you want to learn. And the board and all the software is only $32.

and what type of processing system do I need?

Just a PC, a cable and the board.

They have timers and such, yes, but they aren't like the ladder logic in a PLC. I've done some PLC work, so I know what that is like.In JAVA is there timers and such that you can program like you can with an allen bradley or GE latter logic functions.

Just to make sure we aren't misunderstanding things, the controller board gets programmed in C or C++ and I am proposing that the user interface application that runs on the PC would be programmed in Java.

although I would like to learn a new way to program and if this way that your talking about can be done witha 50 doller processer and some relays I AM THERE

Well, the board will do it. The java development system for the PC is free too. See www.eclipse.org for more info. But the Java PC stuff is a little bit complicated. If you aren't a programmer, you might want to wait for me or someone else to get the first part of it done and then see if you want to jump in and help in that aspect.

I was going to use therrmel cuppels but thermisters are cheep and very accurate.

I agree.

So I would be happy to share with you some of ideas I have for automation on a brew system. I have found some float switches that can handle up to 180 deg F they are tank switches from mC Master carr by using two of these in your system you can basicly walk away during the sparge system

Like these for $13 ? http://www.durablecontrols.com/plastic.htm Its a crying shame not to have the pump automated during the sparge when the sensor only costs $13 !

I am using 120v AC solinoid valves and a magnitic drive pump to control flow. But my system is totally different from most, its an interesting set up with the hot h2o tank (electric 2 3000 watt elements @ 240 vac = 25 amps) (any dryer curcut in any garage can handle that ) sitting above the mash tun ( tippy tun) and boil kettel that are on the same plane and they are above the hop back/grant, and everything flows to and from the grant via a pump simple yet affective (I think) I am building it as we speak. anyhow temp control would be nice not having to buy a controler and I have to buy relays for the hot h2o tank anyway.

Temp control is easily doable.

I think we are going to run into a bit of a problem if we try to do everything for every different system at once. I think we will have to start out with something fairly simple, yet more advance than what the current temp controllers do and then add more advanced features to it. I don't know what people are going to do for really nonstandard features. Probably dig in and do some programming themselves.

how hard is it to make on the fly changes to this system your talking about???

Very easy if you can program. I could probably get a simple system up and running in a day and then add a whole bunch of features to it in short time. And once it runs for one, it runs for everyone - provided they have the same kind of system.

Hey Brewman,

I like the design so far but I have one question about the placement of the control box. Is it in a location sufficiently close to allow condensation of the steam from the kettle, HLT, or the heater water? I ask because I'd be a little concerned of condensation damaging any of the controls over the course of many brews. Just a thought but I bet as much thought as you've put into this that I'm simply not seeing your setup spatially to scale.

About using kegs, my RIMS system has 3 kegs and what I've noticed is that I need to follow your suggestion of insulating the mash-tun. For 5 gallon batches the mash-tun maintains temperatures very precisely but when I move up and brew 10 gallon batches my 3500W heating element has to cycle on quite often. I sometimes need a very low flame on the burner under the mash-tun to help maintain the temperature. I'm replacing the 3500W this weekend with a 4500W 240V element that is twice as long and I may end up having two 4500W burners. I'll need to see how it works out. I think when I'm at the store I'll shop around for an insulation jacket for the mash-tun.

I'm 5'11" or so SWMBO says but I'm more like 5'9" and I find my stand to be a little too high for visual inspection during brewing and I like to see what is taking place in the mash-tun as far as foaming,frothing and the flow rate. I just stand on a step stool but I"d much rather just lower the stand so that I can flat footed have a look-see. If you've seen a BrewMagic Pro http://www.kegs.com, that is the type of stand I have and I'm working on a design that will allow me to have the mash-tun on a tippy-dump system. Keep us posted.

Jeffrey

I like the design so far but I have one question about the placement of the control box. Is it in a location sufficiently close to allow condensation of the steam from the kettle, HLT, or the heater water? I ask because I'd be a little concerned of condensation damaging any of the controls over the course of many brews. Just a thought but I bet as much thought as you've put into this that I'm simply not seeing your setup spatially to scale.

About using kegs, my RIMS system has 3 kegs and what I've noticed is that I need to follow your suggestion of insulating the mash-tun. For 5 gallon batches the mash-tun maintains temperatures very precisely but when I move up and brew 10 gallon batches my 3500W heating element has to cycle on quite often. I sometimes need a very low flame on the burner under the mash-tun to help maintain the temperature. I'm replacing the 3500W this weekend with a 4500W 240V element that is twice as long and I may end up having two 4500W burners. I'll need to see how it works out. I think when I'm at the store I'll shop around for an insulation jacket for the mash-tun.

I'm 5'11" or so SWMBO says but I'm more like 5'9" and I find my stand to be a little too high for visual inspection during brewing and I like to see what is taking place in the mash-tun as far as foaming,frothing and the flow rate. I just stand on a step stool but I"d much rather just lower the stand so that I can flat footed have a look-see. If you've seen a BrewMagic Pro http://www.kegs.com, that is the type of stand I have and I'm working on a design that will allow me to have the mash-tun on a tippy-dump system. Keep us posted.

Jeffrey

I like the design so far but I have one question about the placement of the control box. Is it in a location sufficiently close to allow condensation of the steam from the kettle, HLT, or the heater water? I ask because I'd be a little concerned of condensation damaging any of the controls over the course of many brews. Just a thought but I bet as much thought as you've put into this that I'm simply not seeing your setup spatially to scale.

I don't like it above the water heater either. Truthfully, I am waffling on wanting a large (>3000 watt) element in a small plastic cooler. I'm starting to think that is a recipe for a meltdown or at least significant warpage. The next iteration might go back to a corny for the hot water tank.

I love it when people come forward with ideas and such. This thing is already 5x better than my last setup.

About using kegs, my RIMS system has 3 kegs and what I've noticed is that I need to follow your suggestion of insulating the mash-tun. For 5 gallon batches the mash-tun maintains temperatures very precisely but when I move up and brew 10 gallon batches my 3500W heating element has to cycle on quite often. I sometimes need a very low flame on the burner under the mash-tun to help maintain the temperature. I'm replacing the 3500W this weekend with a 4500W 240V element that is twice as long and I may end up having two 4500W burners. I'll need to see how it works out.

Keep us informed. I'm afraid of RIMS truthfully, due to wort burning. The whole purpose of mashing is to build up enzymes to make sugars. Enzymes are very temp sensitive and higher temps (180F+) can kill some of them. So I'm not sure how I feel about running wort past a very hot (300F) element. I'd love to hear a detailed answer on this. Have you ever measured return wort temp on your system when its running hard, ie heater on quite a bit ?

I think when I'm at the store I'll shop around for an insulation jacket for the mash-tun.

Water heater jackets are supposed to work well.

Lots of people have told me the same thing.I'm 5'11" or so SWMBO says but I'm more like 5'9" and I find my stand to be a little too high for visual inspection during brewing and I like to see what is taking place in the mash-tun as far as foaming,frothing and the flow rate. I just stand on a step stool but I"d much rather just lower the stand so that I can flat footed have a look-see.

runhard: have you ever batch sparged and done infusion mashes and compared how they are to your RIMS ? Do you ever get the feeling that we are making too much of step mashing and fly sparging ? It sure would be a lot simpler to design a system without HERMS or RIMS.

Similar threads

- Replies

- 10

- Views

- 3K

- Replies

- 44

- Views

- 2K

- Replies

- 11

- Views

- 758

Colorado

Nano Homebrew System (10-15 Gallons)

- Replies

- 0

- Views

- 849