Jon Goswick

Active Member

- Joined

- Jun 11, 2019

- Messages

- 35

- Reaction score

- 10

Has anyone here done a CFC with a 1/2" inner? Considering on with 25' of copper, spiral wrapped with a solid #8 wire. Stuffed inside a suitable outer. Thoughts on this?

I have a 1/2" inner copper CFC. Mine is only 12feet long and is 2 straight pipes. It works well for my process. I whirlpool chill 18g batches and can drop the entire batch down to 170 in 2 minutes and additionally I can then whirlpool chill down to 60-70 in about 20 minutes leaving a very nice cone at the end. CheersHas anyone here done a CFC with a 1/2" inner? Considering on with 25' of copper, spiral wrapped with a solid #8 wire. Stuffed inside a suitable outer. Thoughts on this?

Would you be so kind as to post pics(if possible). I'd like to see it plumbed. Curious about pump and flow control.I have a 1/2" inner copper CFC. Mine is only 12feet long and is 2 straight pipes. It works well for my process. I whirlpool chill 18g batches and can drop the entire batch down to 170 in 2 minutes and additionally I can then whirlpool chill down to 60-70 in about 20 minutes leaving a very nice cone at the end. Cheers

Sorry I don't have any pictures of it hooked up but it's pretty straight forward. Just the pump output to the lower connector and the upper connector gets connect to the whirlpool arm in the boil kettle. When I'm finished with the whirlpool hops and completed chilling I just remove the hose from the whirlpool arm and connect it to my unitank which also has the quick connects. Makes it very easy. One thing to mention is this chiller most likely would not work well for 1 pass chilling but as I said previously my goals with this was to get the entire batch chilled equally and quickly down to 170 and additionally not have to move hoses around to get a good whirlpool cone. CheersWould you be so kind as to post pics(if possible). I'd like to see it plumbed. Curious about pump and flow control.

That's a wicked rig bro! Thanks for the pic, got a new idea to work with now. Do you think a third row would increase your delta/decrease time?Sorry I don't have any pictures of it hooked up but it's pretty straight forward. Just the pump output to the lower connector and the upper connector gets connect to the whirlpool arm in the boil kettle. When I'm finished with the whirlpool hops and completed chilling I just remove the hose from the whirlpool arm and connect it to my unitank which also has the quick connects. Makes it very easy. One thing to mention is this chiller most likely would not work well for 1 pass chilling but as I said previously my goals with this was to get the entire batch chilled equally and quickly down to 170 and additionally not have to move hoses around to get a good whirlpool cone. CheersView attachment 631470

Most definitely would. Just for myself it wasn't really worth the extra money and more so the space. CheersThat's a wicked rig bro! Thanks for the pic, got a new idea to work with now. Do you think a third row would increase your delta/decrease time?

Did you leave inner smooth or is it spiralled? And are your ends barbed/flares.Most definitely would. Just for myself it wasn't really worth the extra money and more so the space. Cheers

Has anyone here done a CFC with a 1/2" inner? Considering on with 25' of copper, spiral wrapped with a solid #8 wire. Stuffed inside a suitable outer. Thoughts on this?

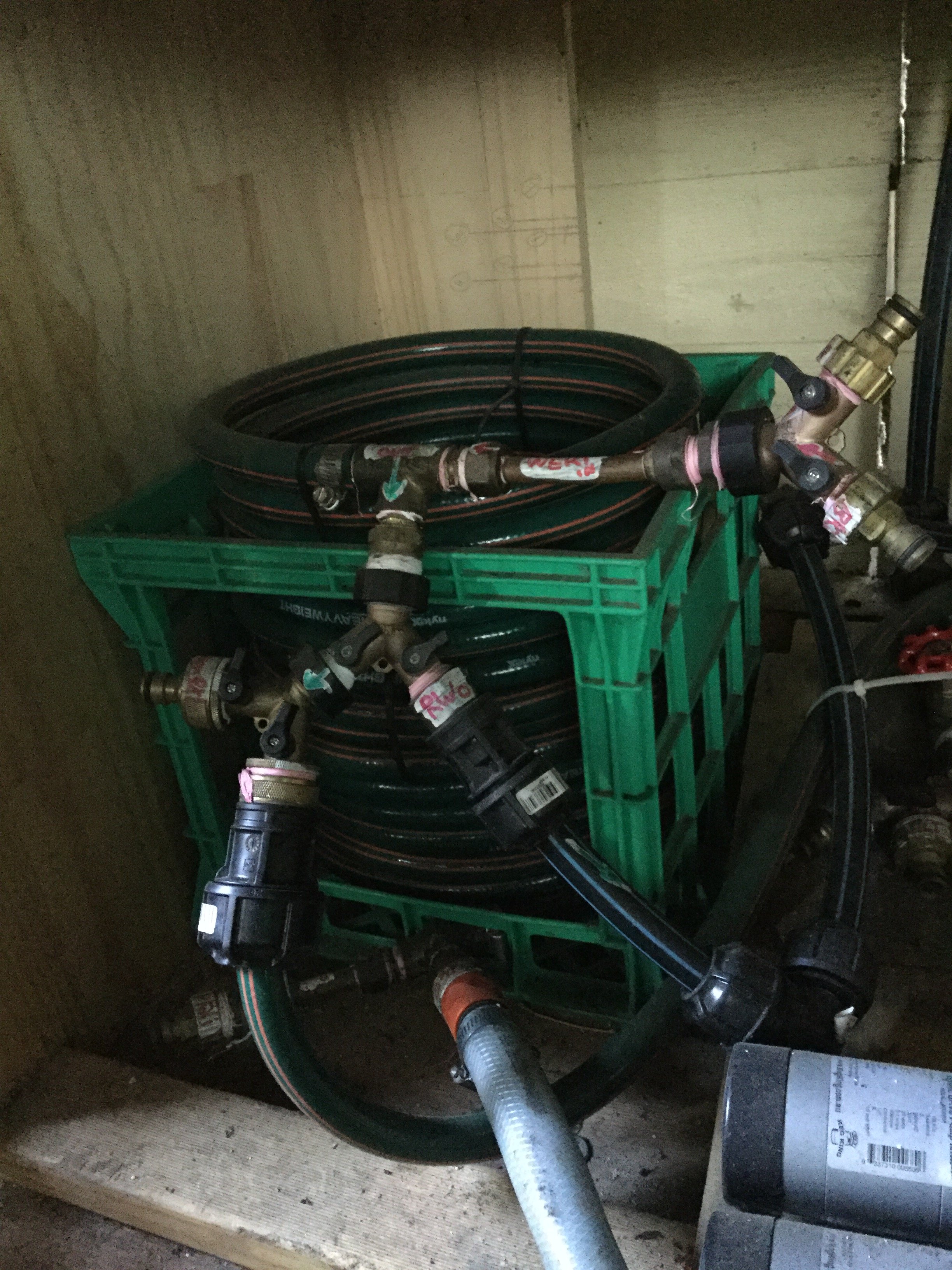

Very nice.I have one of these, made from a wide bore garden hose ?3/8” and 25 foot copper pipe, pipe fittings, cable ties etc.

I do not have copper wire around the outside. It was hard enough getting the 1/2 inch copper pipe down the hose. (BTW I found that detergent did not help the insertion of the pipe)

Firstly it is efficient for cooling but I also use it for heating instead of an immersion coil, which is why I have so many ports off the side arms.

I can get 100C down to 18 in 15 minutes, pumping the counterflow water in a circuit from a 3000L Rainwater tank at about 16 degrees.

Note I put it in a milk crate in case I ever have to move it.View attachment 634076