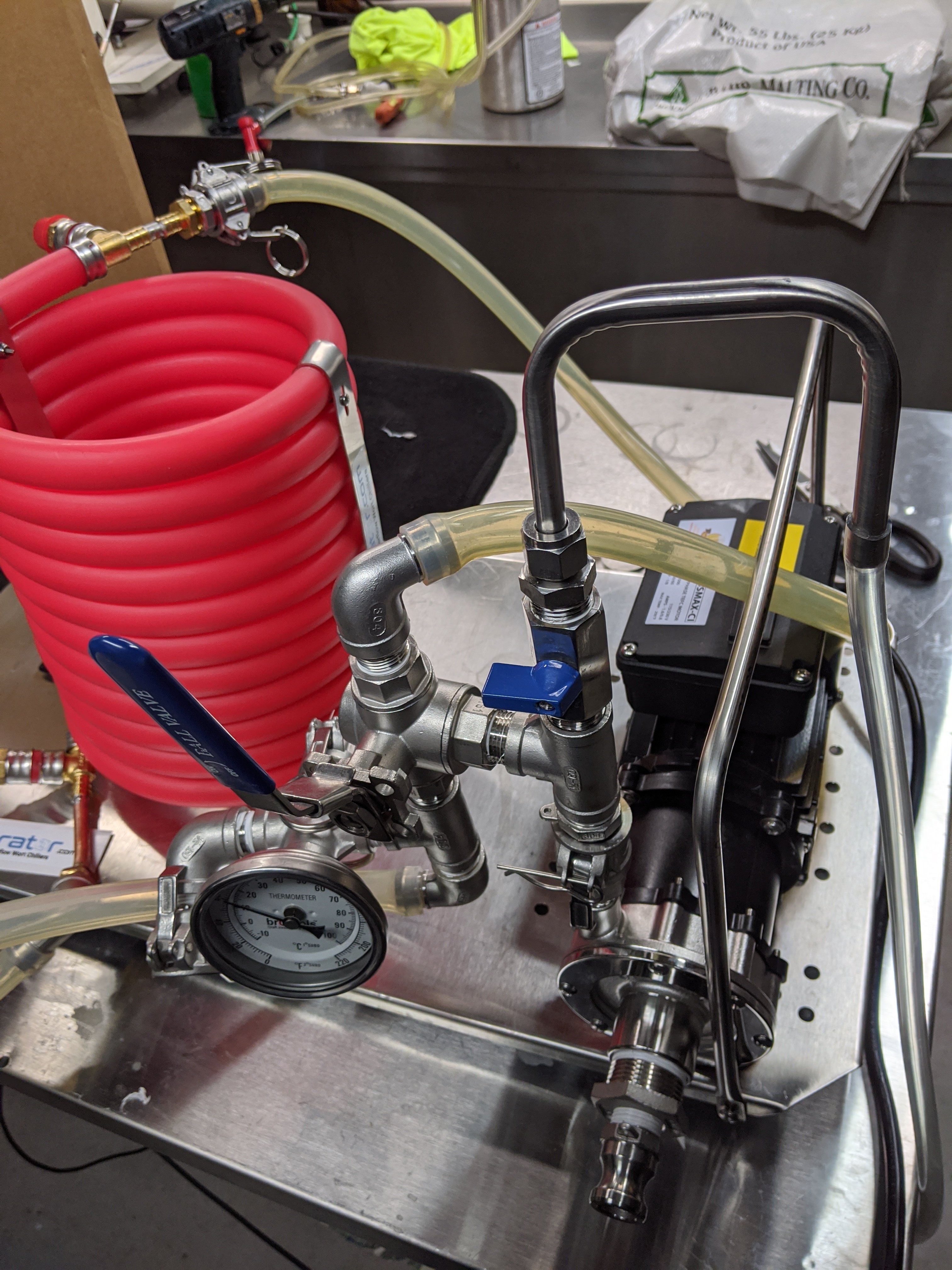

Hi. I have a Spike 20 gallon kettle with a Northern Brewer Stainless Steel counterflow chiller and Blichmann Riptide pump. I have two problems which both point to a flow restriction in the counterflow chiller.

1) when I whirlpool with the chiller in the loop, the whirlpool strength is a fraction of what it is without the chiller. This means I have to whirlpool first, then hook the chiller in and run the chiller. This adds time to the brew day and some wort loss when connections & disconnections are made.

2) when I am doing the cleaning cycle on the kettle with the Spike 1.5” TC CIP ball, it spins very fast and I can’t even lift up the lid a crack to look inside as cleaner sprays out. I can hear the ball spinning. If I loop in the counterflow to clean that at the same time as the kettle, the CIP ball hardly rotates and stops. I can lift the kettle lid and see the ball with liquid coming out but not with enough force to spin the ball.

I have tried this with shorter hoses and with the pump and counterflow on a crate next to the kettle so they are in the same plane as the top of the kettle and the pump doesn’t have to lift the fluid more than a few inches. I have also ensured that the system does not have any air bubbles in it.

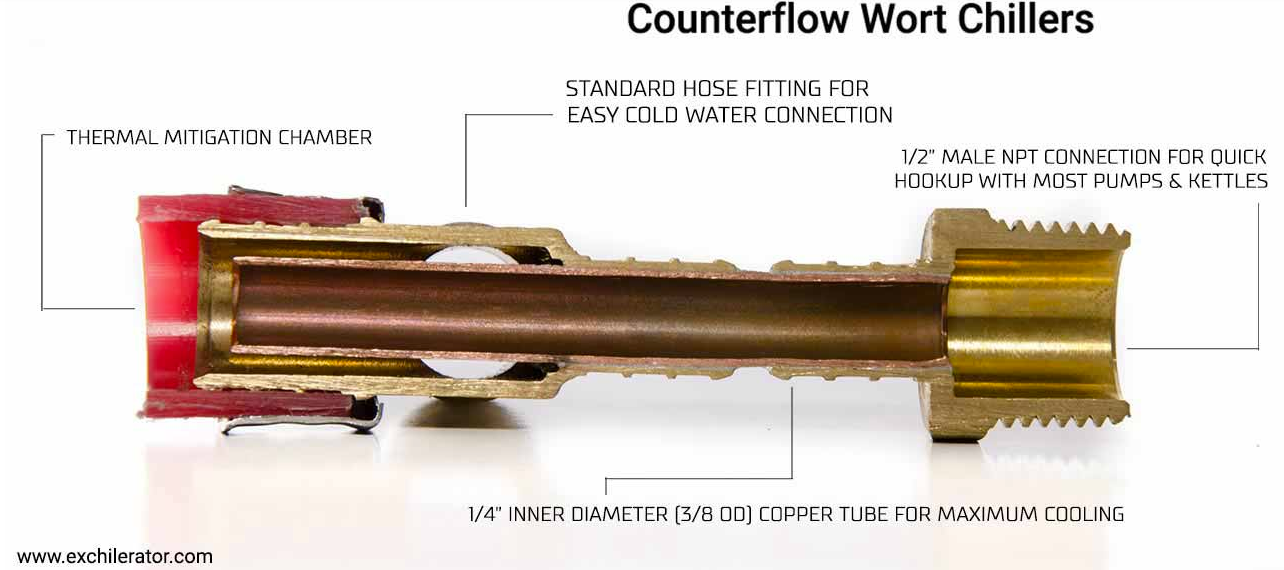

Am I asking too much of this counterflow? The wort pipe OD is advertised as 3/8” so the internal pipe diameter is probably closer to 1/4” diameter, whereas without 18’ of 1/4” pipe in the pump loop, it’s all 1/2” pipe and fittings.

It would sure be nice to clean and whirlpool with the counterflow chiller in the loop as my brew-buddy does with a similar configuration except with a 30 plate Duda Diesel plate chiller.

Thanks,

Paul

1) when I whirlpool with the chiller in the loop, the whirlpool strength is a fraction of what it is without the chiller. This means I have to whirlpool first, then hook the chiller in and run the chiller. This adds time to the brew day and some wort loss when connections & disconnections are made.

2) when I am doing the cleaning cycle on the kettle with the Spike 1.5” TC CIP ball, it spins very fast and I can’t even lift up the lid a crack to look inside as cleaner sprays out. I can hear the ball spinning. If I loop in the counterflow to clean that at the same time as the kettle, the CIP ball hardly rotates and stops. I can lift the kettle lid and see the ball with liquid coming out but not with enough force to spin the ball.

I have tried this with shorter hoses and with the pump and counterflow on a crate next to the kettle so they are in the same plane as the top of the kettle and the pump doesn’t have to lift the fluid more than a few inches. I have also ensured that the system does not have any air bubbles in it.

Am I asking too much of this counterflow? The wort pipe OD is advertised as 3/8” so the internal pipe diameter is probably closer to 1/4” diameter, whereas without 18’ of 1/4” pipe in the pump loop, it’s all 1/2” pipe and fittings.

It would sure be nice to clean and whirlpool with the counterflow chiller in the loop as my brew-buddy does with a similar configuration except with a 30 plate Duda Diesel plate chiller.

Thanks,

Paul

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)