- Joined

- Nov 6, 2007

- Messages

- 62,016

- Reaction score

- 6,922

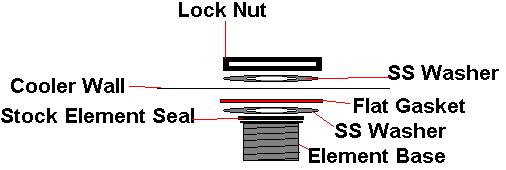

I have a 10G Round cooler. I drilled the hole for my bottom mounted heating element too large. Dumb mistake but what's done is done. I've currenty tried a SS washer on either side with gaskets to seal the deadspace around the element with no luck. I'm thinking it would be easiest to patch the hole in a way that I could bsaically start over. Let me know what you think of this idea.

JBWelding the Heating Element nut to a SS Washer. Then JBWelding that washer/nut combo to the bottom of the cooler. Then just use the stock gasket against the nut. basically making a "welded" fitting for a cooler.

This idea actually just came to me while typing the intro to this thread. I guess the only concern is, do you think JBWeld epoxy would stick ok to the extremely smooth surface of the cooler? This would be to the outside edge, not internal.

JBWelding the Heating Element nut to a SS Washer. Then JBWelding that washer/nut combo to the bottom of the cooler. Then just use the stock gasket against the nut. basically making a "welded" fitting for a cooler.

This idea actually just came to me while typing the intro to this thread. I guess the only concern is, do you think JBWeld epoxy would stick ok to the extremely smooth surface of the cooler? This would be to the outside edge, not internal.