Kopesetik

Member

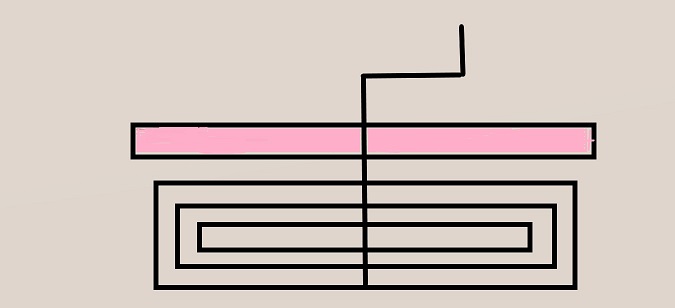

I’ve always used a cylindrical 10 gallon water cooler for my mash tun. Temp stays consistent during rest and I don’t stir often in order to keep the heat in.

Like many brewers, I’m very creative with my engineering. As a mechanic (not auto-mechanic), I have access to various moving parts, hydraulics, motors and actuators.

Would it be beneficial to to have a high torque motor with a stainless steel rod (with branched out arms) attached to through the lid to continuously stir the mash at a very low RPM as to not release tannins? I’ve never really seen home brewers do this...

Tell me to do this and I’ll create and post it!

Like many brewers, I’m very creative with my engineering. As a mechanic (not auto-mechanic), I have access to various moving parts, hydraulics, motors and actuators.

Would it be beneficial to to have a high torque motor with a stainless steel rod (with branched out arms) attached to through the lid to continuously stir the mash at a very low RPM as to not release tannins? I’ve never really seen home brewers do this...

Tell me to do this and I’ll create and post it!