prince87x

Member

- Joined

- Apr 2, 2014

- Messages

- 21

- Reaction score

- 0

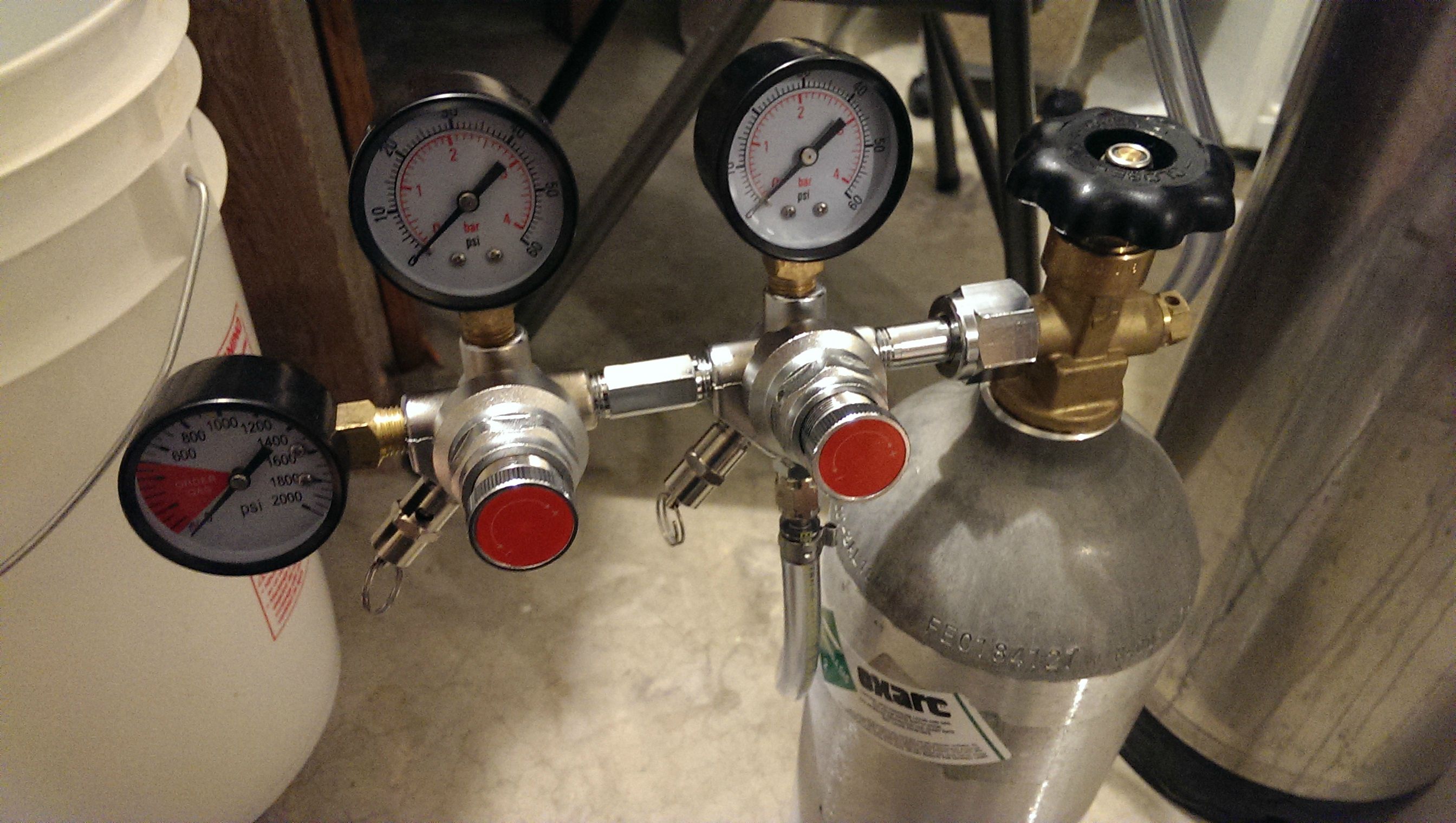

I've just started kegging and bought a full 5 lb tank of CO2. I've hooked up a Brew Logic Double Gauge Regulator to it. I turned the tank fully to the open position and pressure needle does not move up at all. I've turned the red nob of the only line I have hooked up and nothing happens. I've pulled the pressure release and nothing came out so it seems no CO2 is even entering the regulator at all.

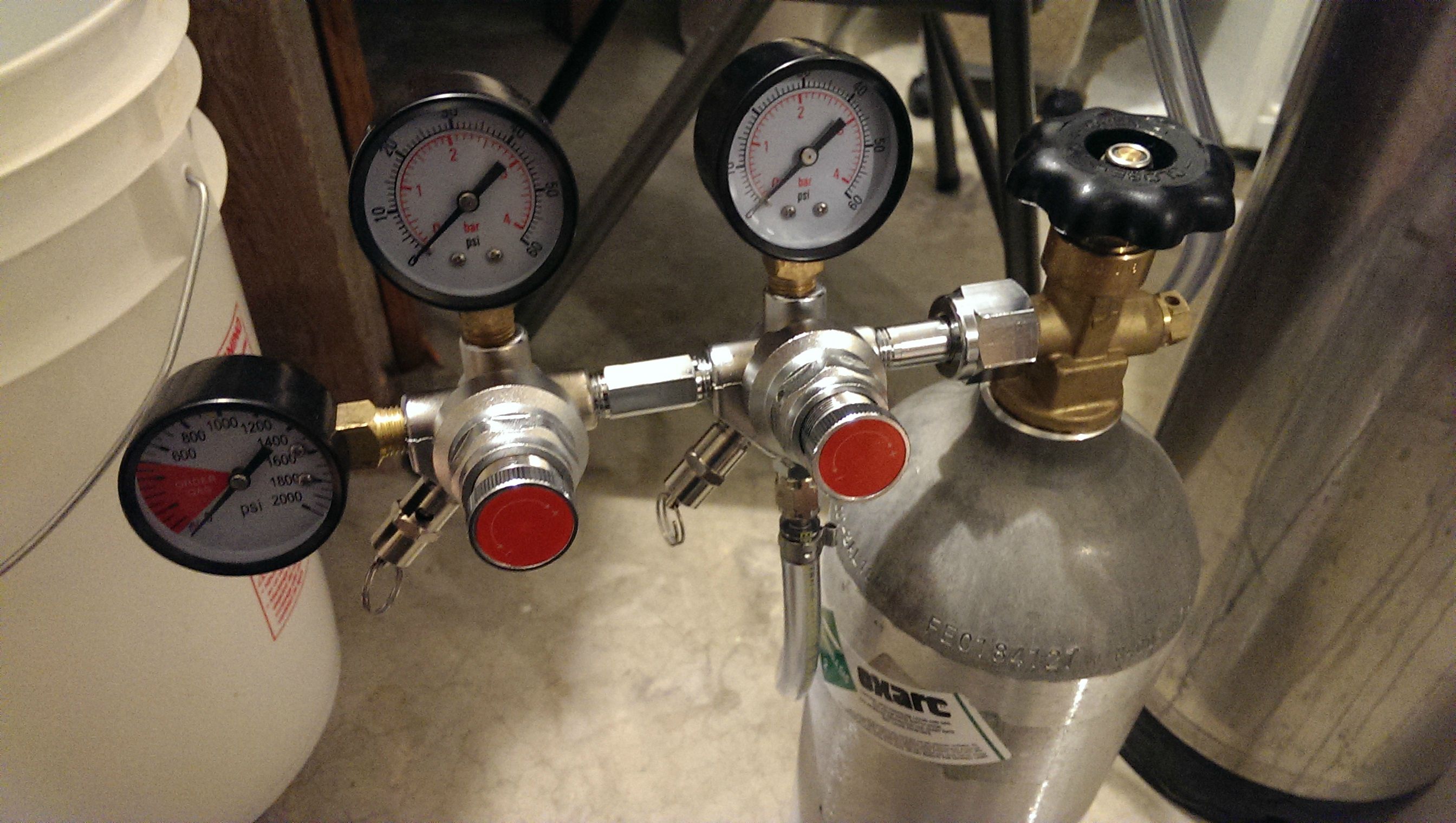

When I untighten the regulator to take it off the CO2 tank I hear a hiss of CO2 so I know it's coming out of the tank and the tank is full. I've tried it with the white plastic washer and without and both times nothing. I've tried pulling out the red knob but it doesn't pull in or out, only turns. I see no levers or anything else so I have no idea why the CO2 is not entering the regulator. I see kind of a golden metal mesh that cones into the regulator but I assume the gas can pass through and that's to stop liquid passing through.

I've attached a picture. Does anyone have any idea what could be wrong?

When I untighten the regulator to take it off the CO2 tank I hear a hiss of CO2 so I know it's coming out of the tank and the tank is full. I've tried it with the white plastic washer and without and both times nothing. I've tried pulling out the red knob but it doesn't pull in or out, only turns. I see no levers or anything else so I have no idea why the CO2 is not entering the regulator. I see kind of a golden metal mesh that cones into the regulator but I assume the gas can pass through and that's to stop liquid passing through.

I've attached a picture. Does anyone have any idea what could be wrong?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)