chuckjaxfl

Well-Known Member

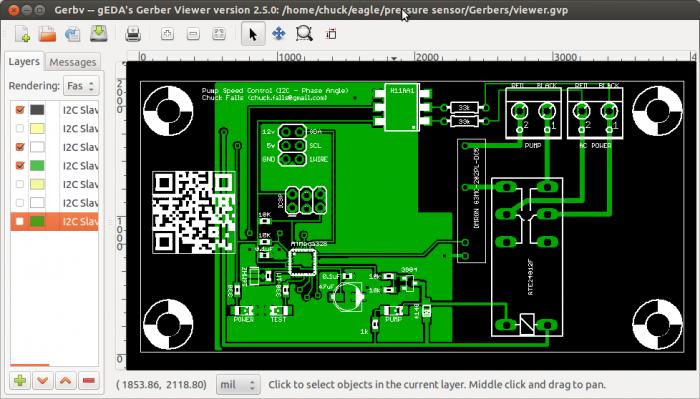

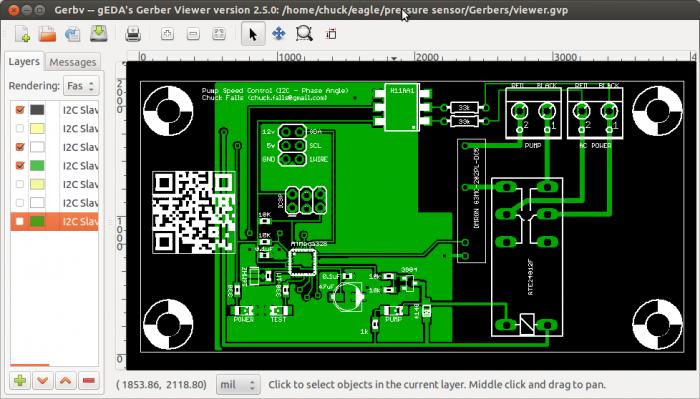

Been at the computer instead of the garage recently. One of the things I want to do is try controlling each pump output by phase-angle controlling the motor instead of putting a ball valve on the exit of the pump head. I recognize that, since our pumps are centrifugal, there's a good chance I'm wasting my time. But, hey, I want to try it anyway.

If it works, I'll use it to control sparge runoff rate, to control the MLT level during sparge, and use it balance chill water vs. hot wort for the chill cycle. If it doesn't work, I just wasted a Saturday drawing up this board. I sent the board off to the board house, and ordered the parts from Digikey. If it sucks, I'll let you know.

If it works, I'll use it to control sparge runoff rate, to control the MLT level during sparge, and use it balance chill water vs. hot wort for the chill cycle. If it doesn't work, I just wasted a Saturday drawing up this board. I sent the board off to the board house, and ordered the parts from Digikey. If it sucks, I'll let you know.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)