I did a write-up/review of the different chiller products a couple years ago (link

here), for HomeBrewTalk when they were trying to get a regular bit of articles going. For that review, I evaluated:

1. 25 ft immersion chiller

2. JaDeD Hydra immersion chiller

3. Two different Duda plate chillers

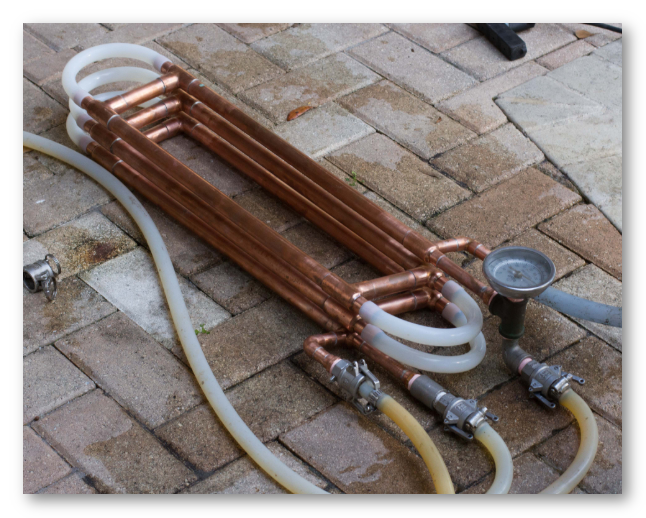

4. Counterflow chiller

I collected data with cooling a volume of water and the times are on that link. There are a number of factors to control when doing this like wort flow speed and water flow speed, so I included those in the data. On some of the systems, flow rate is dictated by/controlled by restrictions in the chiller so I couldn't completely control everything to have it equal.

In summary, the large plate chiller was the fastest, followed by counterflow chiller, then JaDeD, then the standard immersion chiller. There are various pros/cons to each, of course. I was initially enamored by the plate chiller speed. Then I had one clog up on brew day leaving me with 4+ gallons of hot wort with no way to cool it down. I still don't think I've gotten that thing cleaned completely (every time I give it a go at soaking and cleaning, little hop bits come out), so I should probably recycle it. Although the immersion chillers are definitely easy to deal with, I found that if you don't sit and babysit it to bob it up and down, they take a long time. You cool off the wort sitting next to the coil and the rest takes forever to cool. And they don't lend themselves to keeping your pot closed up and protected from random air debris as your lid doesn't fit on top of the pot. I don't think I've ever had a problem, but doesn't mean I'm not paranoid...

So for me the unit I continue to use is the Exchilerator Maxx counterflow chiller. It's fast, I can cool the wort while keeping the lid on my kettle, and I can do other clean-up things while it's chilling the wort. I've never had a clog, and to clean it, I just cycle hot water through it for several minutes at the last part of clean-up. I don't get any residual hop debris coming out of it.

https://www.homebrewtalk.com/wort-chiller-review-comparison.html

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)