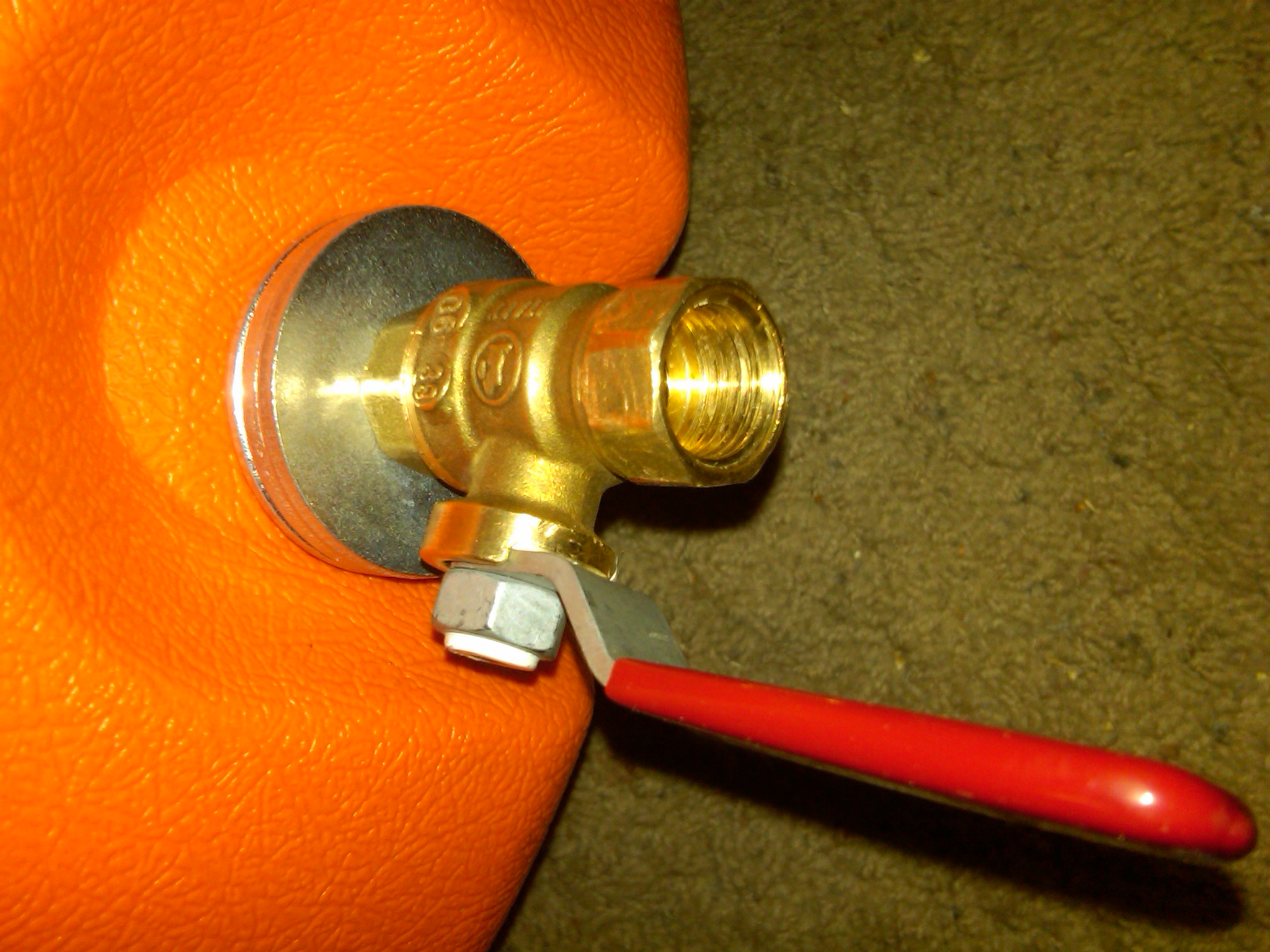

Just made two of these (mash tun and hlt)

A few things:

Stainless steel washers - I couldn't find them on Lowes. They had 1/2 and 3/4 (too small, too big), or some "reinforced" types of non-descript material (yellowish, not brass). On Home Depot, I found this box - it's on the nuts & bolts section, there is a section just for these "create a bolt" orange boxes (they're not on the drawers, they're hanging on the wall). Flat washers not visible on photo because I used them

I used the short nipple (a-785?) instead of the a-786. With that, I could fit with only one SS washer on the inside, and one zinc-plated (thicker, smaller diameter) washer on the outside. The tap touches the wall when closed, but it's still barely able to close the full way.

I got the coolers from Ace, and the two were slightly different (although with the same model code, upc, everything). In one of them the tap hole has an indentation around it, so I could only fit the zinc washer - the ss one was too big. I'm starting to think the walls on that one are thicker - I may have to check which one holds more heat. As long as you've got the smaller washer for the outside, the instructions work for both, though.

I got the o-rings from fred meyer in their faucet section. They have a "faucet repair kit" that includes like 8 o-rings of different diameters.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)