jwhazel

Active Member

To be more concise, is this a dumb thing to do for mash recirc and whirpool of 5gal batches? I plan to T the output so I have two valves available. The ease of cleaning would be nice, but I'm not sure if I would run into flow control issues.

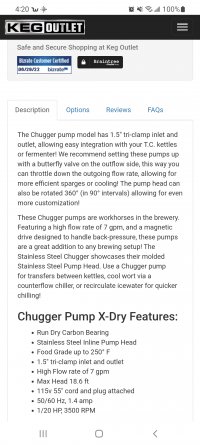

Background: I got a killer deal on a bunch of used equipment and they threw in a chugger TC pump with a ton of 1.5" butterfly trigger handles. While it seems like overkill and not something I would seek out if buying new, the equipment is here in front of me (I just need to buy a T piece to complete it). If it's not wise to do, then I'll need to also track down some TC ball valves. TIA for any sage advice.

Background: I got a killer deal on a bunch of used equipment and they threw in a chugger TC pump with a ton of 1.5" butterfly trigger handles. While it seems like overkill and not something I would seek out if buying new, the equipment is here in front of me (I just need to buy a T piece to complete it). If it's not wise to do, then I'll need to also track down some TC ball valves. TIA for any sage advice.

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)