rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

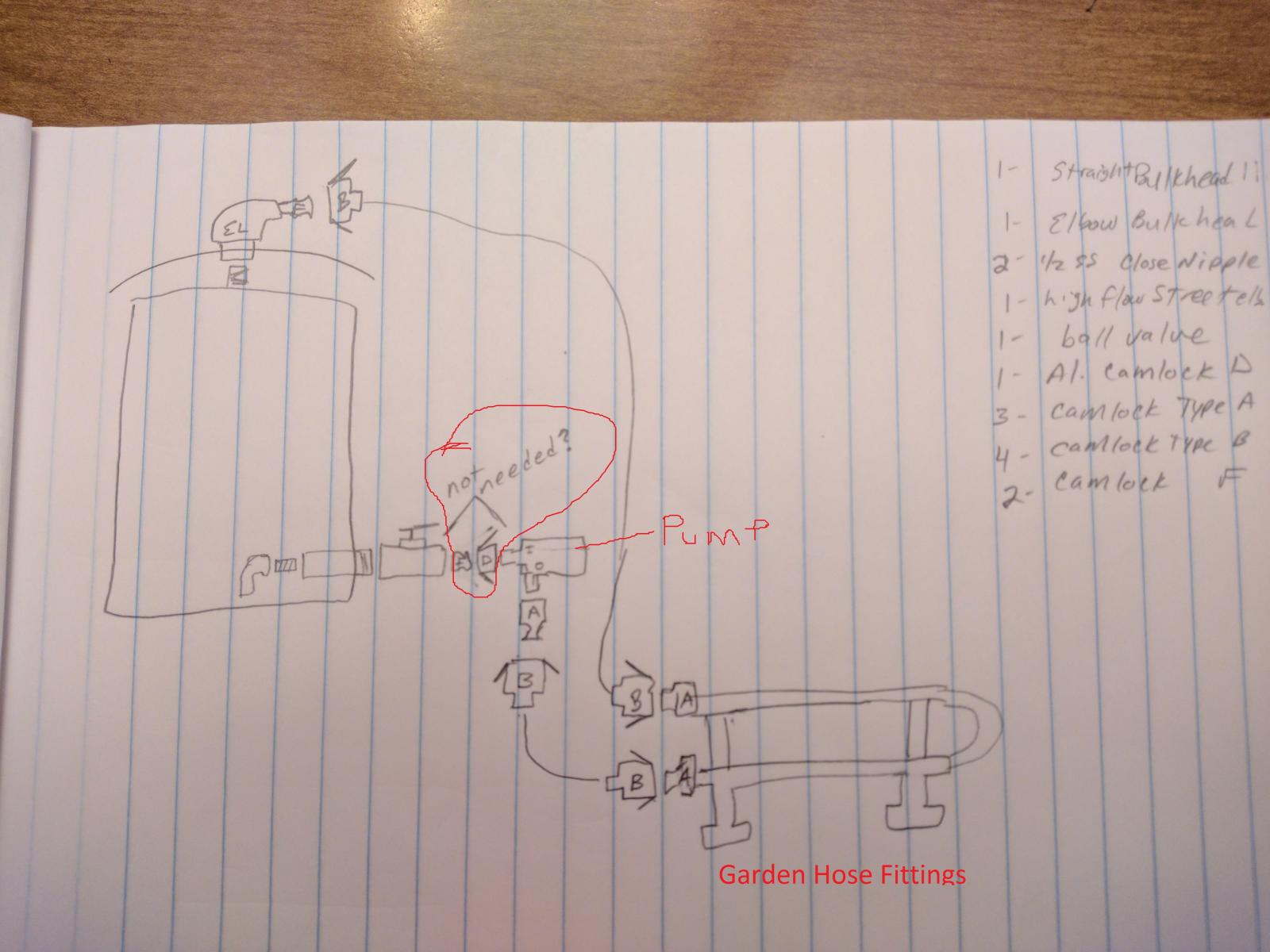

Even with all the explanations of camlocks and various fittings, I still question whether I am planning my new BIAB setup correctly. Here's a picture of my plans for a BIAB system with a pump added. I didn't draw in the heating element or false bottom in the kettle.

I'm thinking I might not need the camlock between the valve and the pump since I'll need the pump whether I'm recirculation to keep mash temps or when running through the Counter-flow-chiller. I can't think of a time I won't need the pump connected. So can I eliminate that camlock? The only reason I may not want to eliminate that camlock is for removing and cleaning.

Otherwise, does the rest of the parts make sense? I tried to label each fitting - though it may be hard to read.

Any suggested changes?

Thanks.

I'm thinking I might not need the camlock between the valve and the pump since I'll need the pump whether I'm recirculation to keep mash temps or when running through the Counter-flow-chiller. I can't think of a time I won't need the pump connected. So can I eliminate that camlock? The only reason I may not want to eliminate that camlock is for removing and cleaning.

Otherwise, does the rest of the parts make sense? I tried to label each fitting - though it may be hard to read.

Any suggested changes?

Thanks.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)