I already have a dedicated small freezer I use as a lager chamber for 5 gal bucket or 6.5 gal corny keg. Heat pad too... all controlled by inkbird.

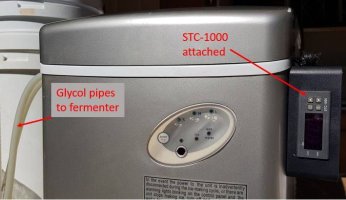

I want to multi-purpose this freezer to temperature control (cold side) on a Spike CF-10 I just picked up off FB mktplace. (Crazy deal ... Came with glycol, hosing, container, pump, and fittings, Woo woo).

Step one:

Remove top door. Make a small collar (2*4) to run hoses, power for pump, and still be able to open lid easily (top door model). Easy... A little box shape with nice corners, solid! ... Attach to the freezer with silicone adhesive. Re-attach top door.

Step two:

Take my extra set of chiller coils (6 1/2" diameter of coil bundle) and use as a heat exchanger for the return of the glycol from the fermenter. The coil is placed in a 12 qt bain Marie (a ss cylinder used in cooking/serving food) which is inside the freezer. The bain Marie (10" dia, about 10" high) (Marie bain?) is filled with glycol/water blend. The glycol in the bain Marie is not pumped to the fermenter... It serves to cool the return glycol from fermenter before dumping glycol in the glycol container #1 w. pump used to cool fermenter .

So ... The chain... The glycol container with pump... Pumps to the fermenter ... Which returns to the freezer, to the cooling coils in bain Marie (heat exchanger... Cooling return before dumping glycol back in the glycol container with pump.

Still waiting on parts and little doohickeys before the build begins. Planning and measuring and ciphering time makes for an easier build. I included a pic to help explain the idea ... I don't have the bain Marie yet (it's like a bucket, less flare from top to bottom) .. coming in a week or so.

The corny shown is a 6.5g corny used for fermenting lagers ... I don't think I will be able to lager and cool fermenter at the same time - I am planning on making the freezer very cold and doing just one task at a time.

I want to multi-purpose this freezer to temperature control (cold side) on a Spike CF-10 I just picked up off FB mktplace. (Crazy deal ... Came with glycol, hosing, container, pump, and fittings, Woo woo).

Step one:

Remove top door. Make a small collar (2*4) to run hoses, power for pump, and still be able to open lid easily (top door model). Easy... A little box shape with nice corners, solid! ... Attach to the freezer with silicone adhesive. Re-attach top door.

Step two:

Take my extra set of chiller coils (6 1/2" diameter of coil bundle) and use as a heat exchanger for the return of the glycol from the fermenter. The coil is placed in a 12 qt bain Marie (a ss cylinder used in cooking/serving food) which is inside the freezer. The bain Marie (10" dia, about 10" high) (Marie bain?) is filled with glycol/water blend. The glycol in the bain Marie is not pumped to the fermenter... It serves to cool the return glycol from fermenter before dumping glycol in the glycol container #1 w. pump used to cool fermenter .

So ... The chain... The glycol container with pump... Pumps to the fermenter ... Which returns to the freezer, to the cooling coils in bain Marie (heat exchanger... Cooling return before dumping glycol back in the glycol container with pump.

Still waiting on parts and little doohickeys before the build begins. Planning and measuring and ciphering time makes for an easier build. I included a pic to help explain the idea ... I don't have the bain Marie yet (it's like a bucket, less flare from top to bottom) .. coming in a week or so.

The corny shown is a 6.5g corny used for fermenting lagers ... I don't think I will be able to lager and cool fermenter at the same time - I am planning on making the freezer very cold and doing just one task at a time.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)