Technically you can use this heatsink when SSR runs on 25Amp but it sets SSR on the edge and its lifespan will be shortened significantly.

Lest dive in some numbers.

Typical 40Amp SSR has a BTA41 triac inside to control a power. It has a 1.2V voltage drop. Considering

P= UI we get that on 25 Amp it will generate 25x1.2 =30Watt of heat. And you need to dissipate that heat.

Amount of dissipated heat can be calculated as

Ph = (Tsource – Tambient) / Rt Where

Rt is a thermal resistance.

Tsource is temperature of heat source. In our case it’s a triac silicon (junction)

Thermal resistance is a sum of Juction to case (

Tjc), case to heatsink and heatsink to air resistances -

Rt = Rjc + Rch + Rha

According to BTA41 datasheet

Tjc is around 0.9 C/W

Typical

Rch if you are using thermal grease is round 0.5 C/W

And this particular heatsink has

Rha = 2.4 C/W

As a result you have

Rt = 0.9 + 0.5 + 2.4 = 3.8 C/W

Now you can calculate triac silicon temperature. Equation is

Tj = P * Rt + Tambient

So if you have 30Watt power source and ambient temperature is 25C junction temperature will be

T = 30 * 3.8 +25 =

139C

Which is below but very close to maximum allowed junction temperature (150C).

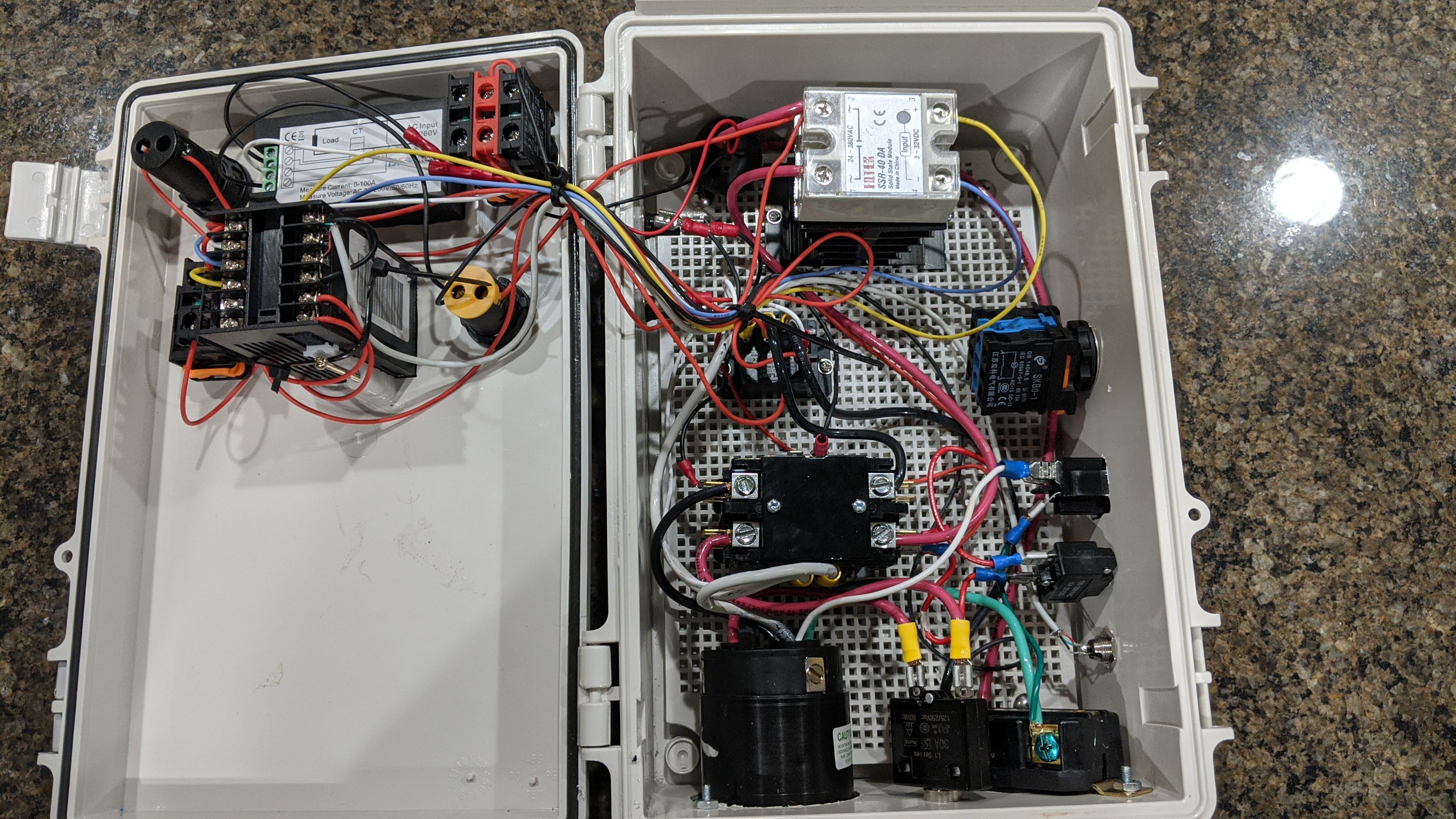

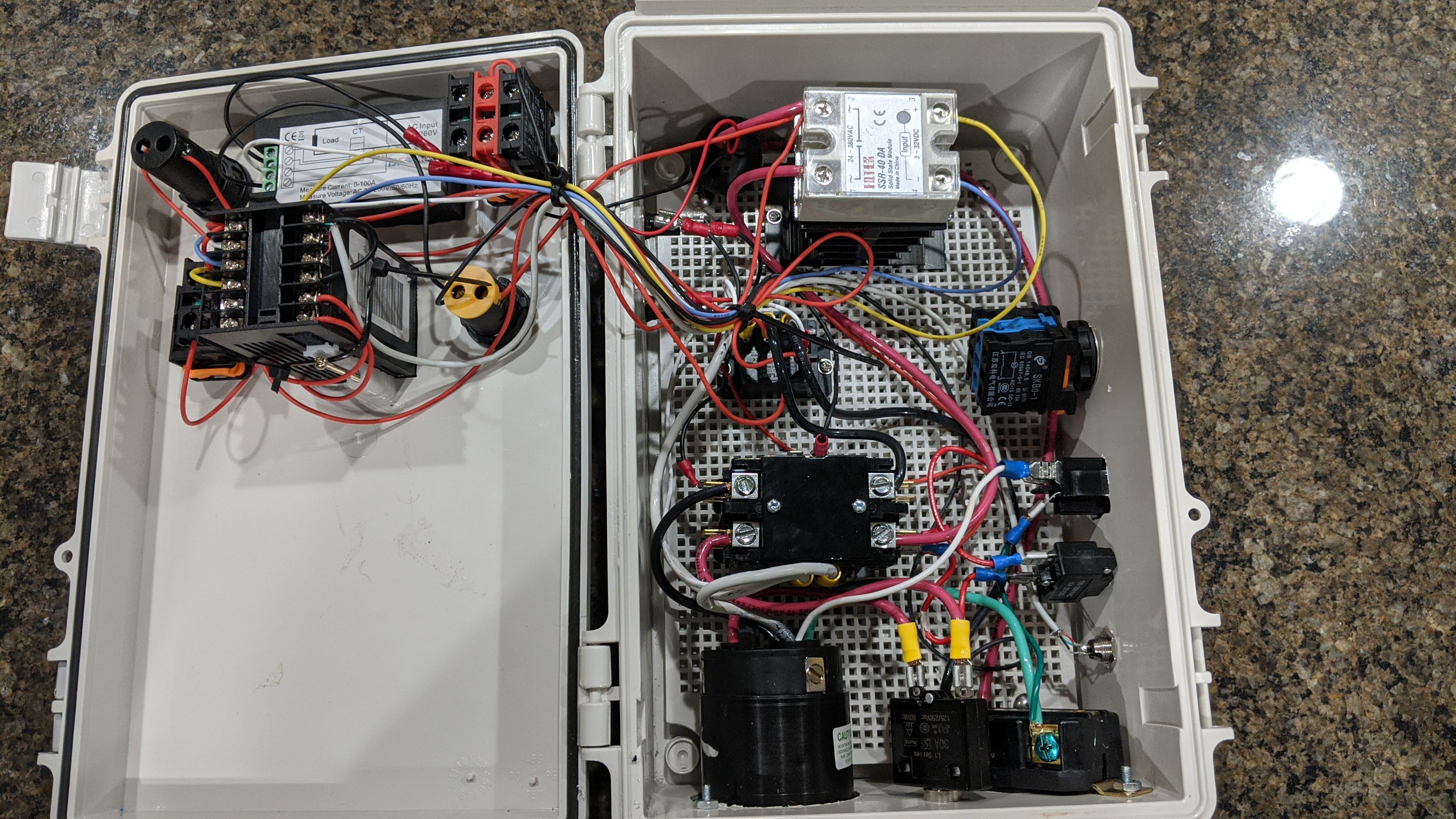

However if you put this heatsink in relatively small un-ventilated box a temperature inside the box can easily raise to 40C or even more. In that case junction temperature will be out of limit. But anyway running silicon close to its limit wiil dramatically shorten it’s lifespan .

To be on safe space you need to keep junction temperature below 100C. It give us

P = (100-25) / 3.8 around

20W of dissipated power.

And 20 W / 1.2V gives us around

16Amp if ambient temperature is around 25C.

https://www.wolfautomation.com/media/pdf/heatsinks/carlogavzzi/cg-hfnine-heatsink-datasheet.pdf

https://www.mouser.com/datasheet/2/848/BTA41-600B-1382474.pdf