BeerCanuck

Well-Known Member

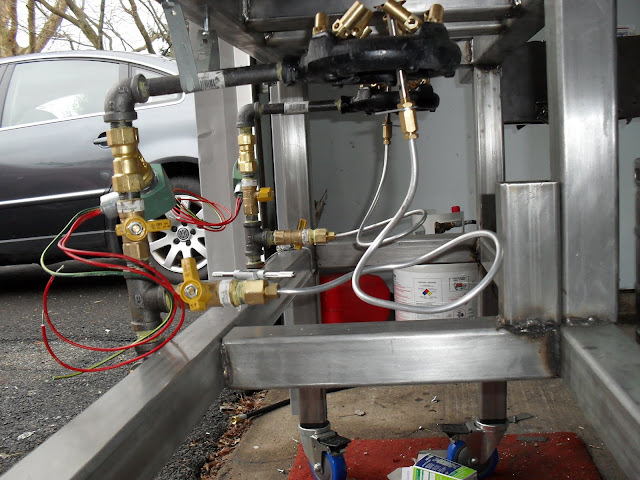

Sweet looking rig willynilly

You should film the rigs maiden run with appropriately themed music playing in background; bow-chicka-wow-wow

Cheers;

BeerCanuck

You should film the rigs maiden run with appropriately themed music playing in background; bow-chicka-wow-wow

Cheers;

BeerCanuck

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)