OK Tribe Fan and Silver Is Money (and everyone else)

I think that I have Bru'n Water figured out, me futzing with the numbers enough to add 4.4g of Gypsum, 4.4g of CaCl and 3.6g of Baking Soda for my 14.5 gallons of water before mashing to reach the near the suggested numbers. This I can understand.

But when using MME, I enter the same grain bill and you're telling me that I don't need to add any water additions and I still can get a similar mash pH? But I also thought that mashing is better or more efficient when these minerals are added and you end up with better tasting beer. Am I wrong here? Are minerals good to add, or not? Why don't we all just brew with RO water and no minerals added?

And yes, the dropdown options for the grains confused me as well - I don't know what types of grain apply to which dropdown option. But that's my lack of knowledge by being a new all-grain brewer. I'm sure I'll get there eventually.

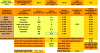

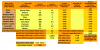

Here is what I get with Bru'n Water and MME:

The bottom image is what MME calculated before I changed the water additions to zeros. Is it that MME says I only need to add a small amount of Baking Soda. Is that grams/gal? OR grams for the entire 14.5 gallons of water?

And in the last screenshot, telling MME to use the same additions in the same quantity as Bru'n Water - different Baking Soda amounts and I end up with different mash pH. I just figured out that MME is calculating the acids/base to add automatically, based on my pH goal?

I also noticed that when I entered the same additions to MME as I chose in Bru'n Water, the ppm numbers were very similar.

How can I change the Baking Soda amount to change the estimated pH in MME?

Since Bru'n Water has some suggestions on goals for ppm numbers, I have to say I like that better. Even though I don't know if those suggestions are correct or not. But being a new all-grain brewer, I don't have the knowledge to tell what my goals should be.

These water calculators have a tough job... Be easy enough for people like me who have no clue what Grist Buffering Capacity is or how to get that info and complex enough for people who really know what they're talking about.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)