ButtonFoo!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BruControl build planning

- Thread starter adman

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Heh. Yes, still very much in testing. Some things have real names, others, well...

The faceplate looks like it'd make a neato halloween mask; the eyeholes and mouth vents are perfect and remind me of something an evil robotic goalie might wear. But to get back on topic, lookin' good!

RIMS element and pump water tested! Now waiting on remaining valves and fittings to arrive from China. After that, I need to figure out how to attach the plumbing skirt to my shelf, and then it's a lot of valve/sensor wiring. Lots more work to do, but I'm slowly getting closer...

Progress report (no pictures this time, sorry): most of the way done with splicing, soldering, heat shrinking, and sleeving all of my valve and sensor wires. Still waiting on two more 3-way valves to arrive from China (weirdly by way of Bahrain, with this shipment). I'm about 50% done with the internal low voltage wiring from the mega/relays to the connectors in the bottom plate. Temp sensors are wired and functioning. 1 of 2 volume sensors are wired and functioning. My plumbing skirt board is painted and ready to be mounted to the brew stand, after which time I'll be able to mount the pumps/RIMS and hopefully get things plumbed.

Getting closer!

Getting closer!

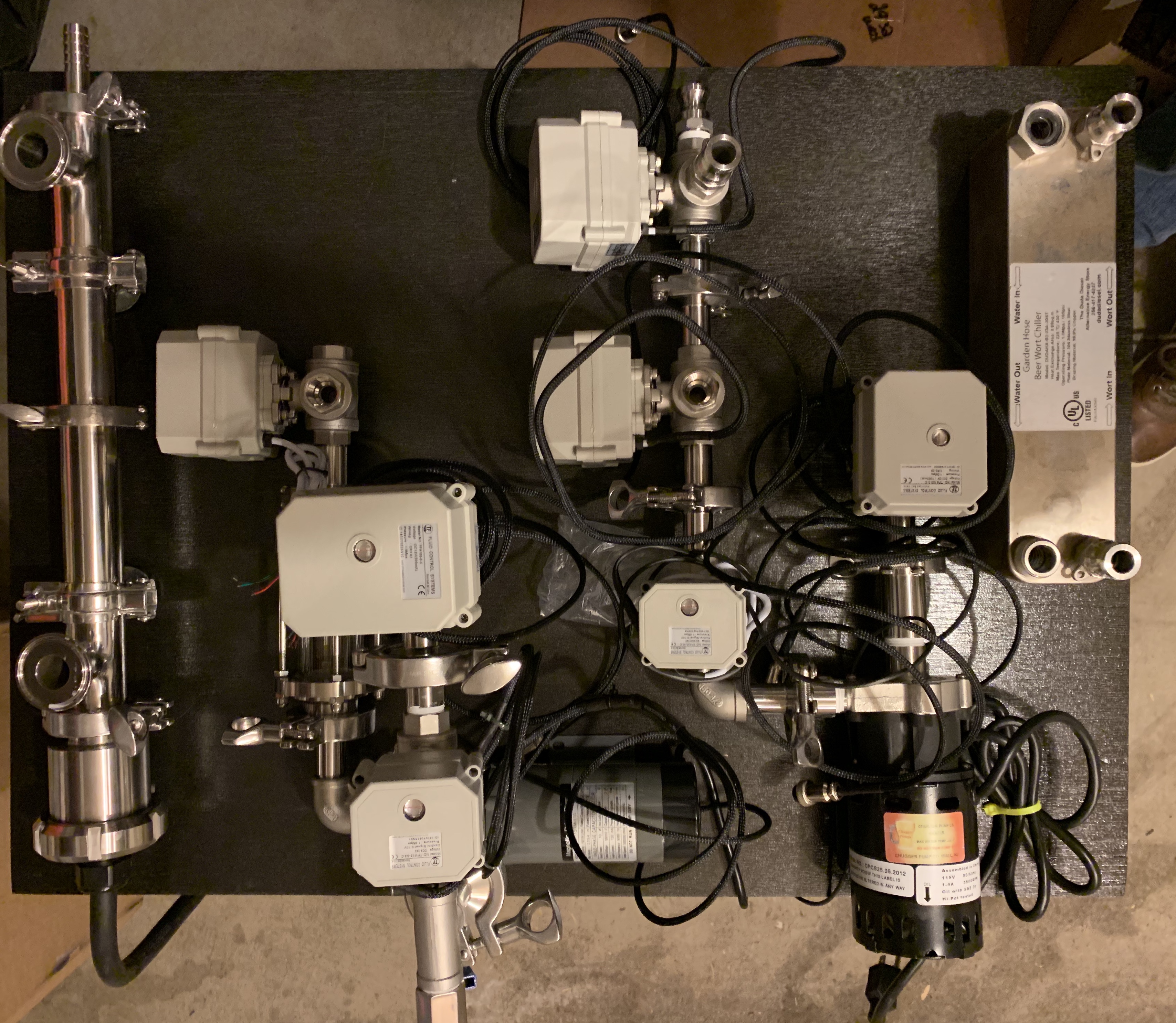

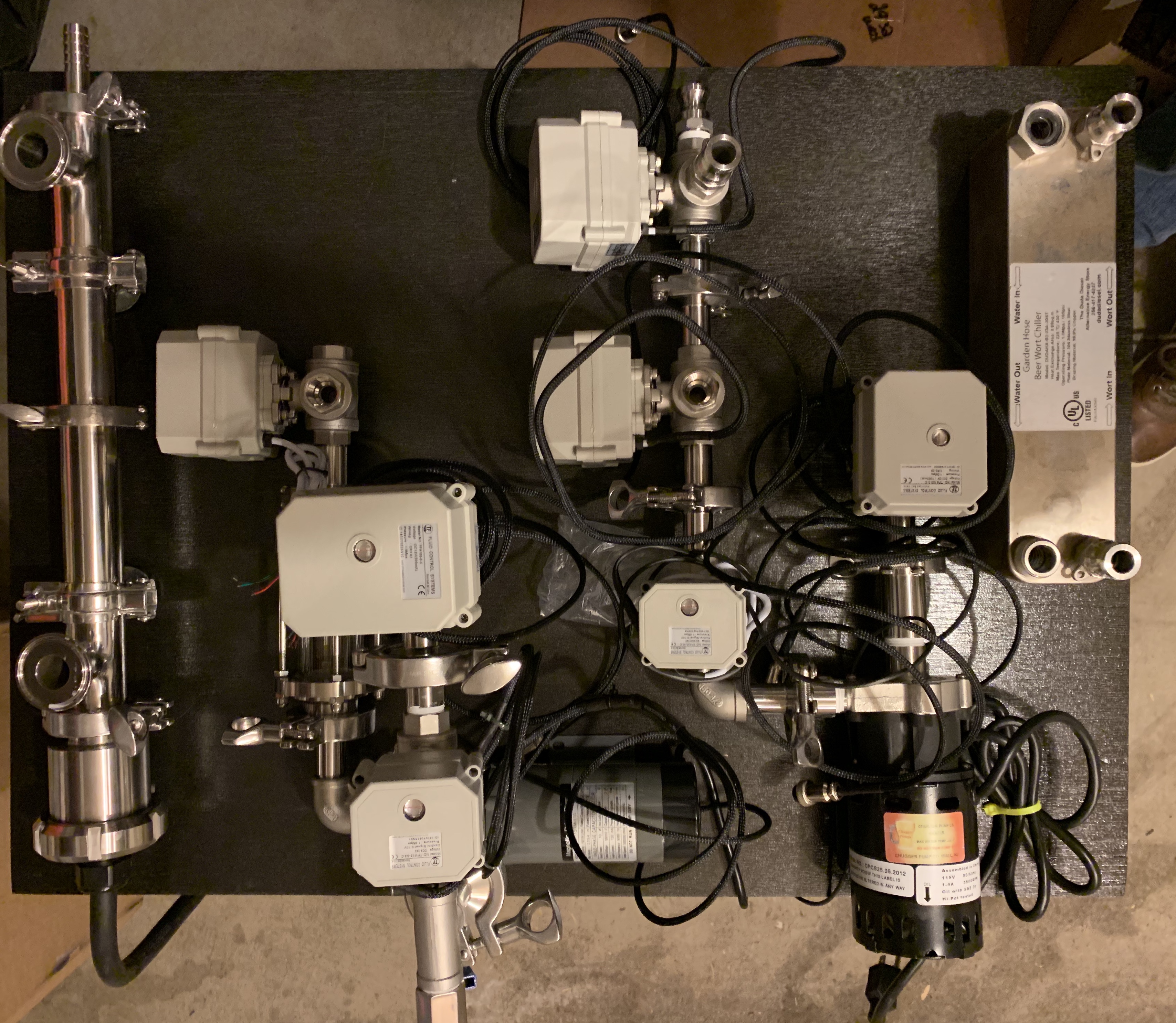

Dry fitting pumps and valves on the plumbing skirt.

Last edited:

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

A couple of other bits of recent progress: my temperature and pressure sensor combo reads both with a single kettle hole (and it's removable for cleaning).

Also, I attached my plumbing skirt to the stand via some simple hinges. Most of the time it will be vertical (including during brew sessions). But I can swing it up to access the keg storage underneath.

Even closer now! I've started work on my brew script, and I'm hopeful that I'll be able to hook everything up for testing shortly after the holidays.

Also, I attached my plumbing skirt to the stand via some simple hinges. Most of the time it will be vertical (including during brew sessions). But I can swing it up to access the keg storage underneath.

Even closer now! I've started work on my brew script, and I'm hopeful that I'll be able to hook everything up for testing shortly after the holidays.

Nice!

Another incremental update, plumbing completed!* Pro tip: do a better job of planning your plumbing than I did. I ended up making 5 or 6 separate orders for fittings after realizing (5 or 6 times) that I'd ordered too few of something.

* Except for the garden hose between the first 3-way valve and the chiller. But at least that should be pretty plug and play and won't involve any hose cutting, etc.

* Except for the garden hose between the first 3-way valve and the chiller. But at least that should be pretty plug and play and won't involve any hose cutting, etc.

Starting to look like something!

CadiBrewer

Well-Known Member

On the kettle on the left, what is the sensor on the top of the tee coming out of the bottom right side of the kettle?

@BrunDog: I know, right? I’m getting excited to finally brew on this thing.

@CadiBrewer: That’s one of two combo rtd probe/pressure sensors for volume measuring. There’s a closer up pic in post 47 above.

@CadiBrewer: That’s one of two combo rtd probe/pressure sensors for volume measuring. There’s a closer up pic in post 47 above.

CadiBrewer

Well-Known Member

Thanks! I was trying to figure out how to mount the pressure sensors in my build and that seems ideal for my setup. You've saved me a huge headache.

On your chiller, in the picture it looks like both the wort in and wort out ports are plumbed to the output side of your pump. I'm sure that's just the angle in the picture.

On your chiller, in the picture it looks like both the wort in and wort out ports are plumbed to the output side of your pump. I'm sure that's just the angle in the picture.

Just FYI, if you want to do it exactly like I did, you need 150mm long RTD probes. Auber has them, but I got mine for a bit less (plus a lot of waiting) from aliexpress.Thanks! I was trying to figure out how to mount the pressure sensors in my build and that seems ideal for my setup. You've saved me a huge headache.

On your chiller, in the picture it looks like both the wort in and wort out ports are plumbed to the output side of your pump. I'm sure that's just the angle in the picture.

Re: the plumbing, yes, I have my chiller plumbed to go back into the kettle if I want to chill the whole batch rather than run directly into the kettle. There's a 3 way valve on the chiller, so I can run directly into the fermenter if I want. For anyone who cares, here's a diagram of how my system is plumbed:

CadiBrewer

Well-Known Member

Ahhh, with your plumbing drawing, it makes sense.

I like the pressure sensor tee mounted on a camlock. Will allow cleaning later. This design is a lower cost and likely easier way to add pressure sensors than flush diaphragm style, and the vertical orientation creates an air gap which allows for sensors with small holes to be used (no junk inside).

CadiBrewer

Well-Known Member

Do you have a link to those sensors? I found about 20 on Aliexpress. Thanks!@CadiBrewer: That’s one of two combo rtd probe/pressure sensors for volume measuring. There’s a closer up pic in post 47 above.

@CadiBrewer: High-temp sensor for brew kettle, and, if you care, the 150mm rtd sensors I used with the tee. The sensor I'm using for my mash tun appears to be the same sensor as the high-temp one, but in a less robust enclosure. The link from my orders no longer works for that one. With all of these things, you need to specify that you want NPT threads in your order. Or ask the seller before you order to confirm that NPT is available. Oh, and you need to specify the pressure range you want for your sensor. I went with 0-6 kPa. Let me know if you have any other questions.

CadiBrewer

Well-Known Member

Thanks a ton, that's extremely helpful.

CadiBrewer

Well-Known Member

@CadiBrewer: High-temp sensor for brew kettle, and, if you care, the 150mm rtd sensors I used with the tee. The sensor I'm using for my mash tun appears to be the same sensor as the high-temp one, but in a less robust enclosure. The link from my orders no longer works for that one. With all of these things, you need to specify that you want NPT threads in your order. Or ask the seller before you order to confirm that NPT is available. Oh, and you need to specify the pressure range you want for your sensor. I went with 0-6 kPa. Let me know if you have any other questions.

I do have one question. What output signal is best for our use - 4-20mA, 0-5VDC, or 0-10VDC?

0-5v

Awesome! Have you run a water test first? Highly recommended if you are using scripts to make sure it runs as expected!

Yes. I have run a couple of water tests. Found several bugs and squashed them. I fully expect to find more, but I'm optimistic that I will make sugar water, and the yeast will do the rest!

First brew is in the bag! Or fermenter, I guess. As expected on any new system, there were many hiccups, but I mostly hit my numbers and there were no show-stopping issues.

Here are the only pics I snapped during the whole 6 hours (how can a 6 hour brew day seem so hectic?): the control panel during the 4th mash step and the sight glass showing some lovely clear wort recirculating.

Now I just need to figure out how to clean up more easily. @BrunDog- how do you get rid of the grains in your mashtun before beginning your CIP routine?

Here are the only pics I snapped during the whole 6 hours (how can a 6 hour brew day seem so hectic?): the control panel during the 4th mash step and the sight glass showing some lovely clear wort recirculating.

Now I just need to figure out how to clean up more easily. @BrunDog- how do you get rid of the grains in your mashtun before beginning your CIP routine?

Looks like sugar water! Congrats! Any feedback on BC's operation (good or bad OK)?

I disconnect the hose into the pump and put it in a bucket. I set a garbage bag on the stand and clamp it to the MT. I use a red solo cup and scoop out the grain into the bag. Then I rinse down the sides, pull the false bottom, and keep rinsing. With the bottom drain, its silly easy to rinse the remainder into the bucket. I then set up the CIP arm.

I disconnect the hose into the pump and put it in a bucket. I set a garbage bag on the stand and clamp it to the MT. I use a red solo cup and scoop out the grain into the bag. Then I rinse down the sides, pull the false bottom, and keep rinsing. With the bottom drain, its silly easy to rinse the remainder into the bucket. I then set up the CIP arm.

Ah, the bottom drain. Yeah, my next mashtun should have one of those.

BruControl worked great. I had some typos/errors in my script in areas I hadn't fully reached in testing, e.g. I had several errors where "sleep", "wait", and "State" were not properly capitalized, which caused the script to error out. But that was user error and I was able to recover--usually by just jumping to the next step. Another brew or two and I'll have almost all of the bugs ironed out.

My biggest problems were rustiness and unfamiliarity--this is only the second time I've brewed in five years, and the first time I've brewed in this house, and on this system. Of course I dumped grains (dry and spent) all over my garage floor, which was fun to clean up, but I got (approximately) the right amount of the right gravity wort in the end.

BruControl worked great. I had some typos/errors in my script in areas I hadn't fully reached in testing, e.g. I had several errors where "sleep", "wait", and "State" were not properly capitalized, which caused the script to error out. But that was user error and I was able to recover--usually by just jumping to the next step. Another brew or two and I'll have almost all of the bugs ironed out.

My biggest problems were rustiness and unfamiliarity--this is only the second time I've brewed in five years, and the first time I've brewed in this house, and on this system. Of course I dumped grains (dry and spent) all over my garage floor, which was fun to clean up, but I got (approximately) the right amount of the right gravity wort in the end.

Lol! OK good to hear!

Similar threads

- Replies

- 8

- Views

- 496

- Replies

- 0

- Views

- 189

- Replies

- 5

- Views

- 1K

- Replies

- 0

- Views

- 326

- Replies

- 43

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)