Well, for a first brew, I'd call it a success. I'll post more photos at a later date when I can get a full report written up; but at this time, here are some notes.

Note: Please forgive my getting some of the jargon wrong!

After refrigerating for over 24 hours, I was finally able to sample my first brew. I opened it very slowly, because I wasn't sure what to expect where carbonation was concerned. I thought that I had only primed with two tablespoons of maple syrup (versus the three called for in the instructions); however, I must have used three after all. When I cracked the seal on the cap, a thin but persistent trail of foam slowly but steadily came out. I gave it a few minutes, letting it drain off into a mug - It didn't amount to much beer, but I didn't want to lose it!

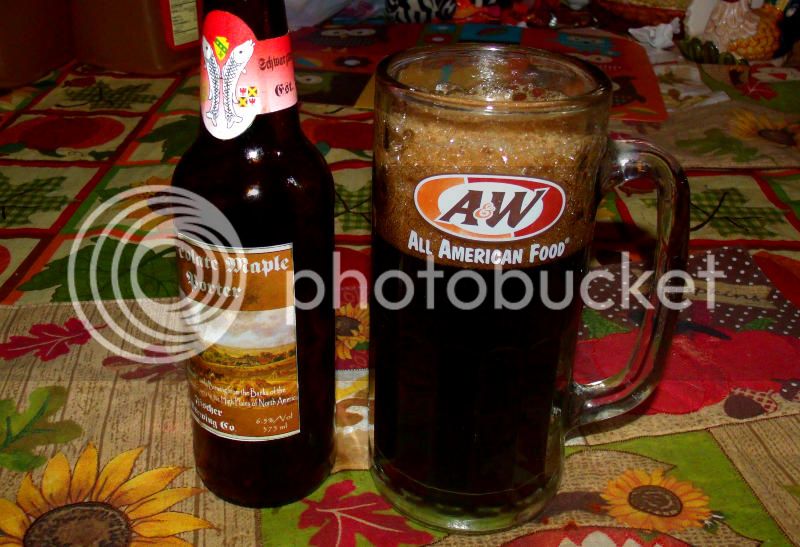

Anyway, the flow of foam eventually slowed to the point where I felt it was alright to finish bringing the cap off. When I poured the beer, it gave a pretty tall, dark head, but it seemed a little thin. I

assume that the head will thicken up (and the carbonation might possibly tone down) with a few weeks of conditioning. In any case, here's how it looked:

Don't judge the A&W mug! It's all I have! LOL....

After waiting a few minutes for the head to settle down, I gave it a try.

Impressions:

The aroma seemed great - rich and complex, with a very definite essence of dark chocolate and a noticable hint of the maple syrup. As I was tipping the mug back to drink, these aromas did pronounce themselves a little more, especially the maple, which was still subtle, yet definitely there.

The mouthfeel was good, as far as I can tell. In spite of the obvious over-carbonation, the

feel of the carbonation as I drank the porter seemed just about right, and what I expect from a beer. This is a minor success for me, as I got

no carbonation when I tried to make root beer last year. The look of the beer as I poured it seemed rich and almost thick due to the nature of the porter, but at the same time, it had a bit of a thin quality to it that implies to me that it would benefit from a little more conditioning.

As for the flavour, I was quite impressed. I've seen a lot of discussion here and on FaceBook pages about using cocoa nibs in "chocolate" beers, but to be honest, I don't think they are necessary at all, when dark, chocolate-roasted grains/malts are used. There was a definite dark-chocolate flavour and finish, with a nice, warm, slight bitterness that was saved from being too much by the subtle maple sweetness. The porter is advertised as 6.5% ABV, and this seems about right, judging by the alcohol "warmth" that I detected - definitely more than most beers I drink, but less than wine or other higher-ABV beverages. There was none of the "hoppy" bitterness that I was worried about; in fact, the fuggle hops worked their way right into the flavour profile beautifully in order to give me a really nice mouthful of autumn day. All of the flavours seemed great, but it was like they all stood apart from each other to an extent. Once again, this leads me to think that the beer is still a little "young."

When brewing this beer, I only had one "SNAFU" that caused me to worry: during the mash, my temperatures got pretty high for just a moment or two - over 180 degrees - and even though I quickly brought the temperature back down, I was worried that this might adversely affect the finished product. As far as I can tell, this did not happen, and it is possible that I simply got the thermometer too close to the bottom of the pot (and thus the burner).

All together, I count it as a pretty dang good success, especially for a first-ever brew with no experience and only the most basic of equipment. As I said, I've only had one or two other porters, and this was easily as good as those; in fact, in some ways, it even was a little better. It simply seemed a little "un-finished" - as I understand, this can be the case with the darker beers, which can benefit greatly from some conditioning time. As someone with experience with sauces and soups, I can easily imagine how great this will be once the flavours and other components have a few weeks to meld and mingle.

Questions:

a) To anyone who has brewed this or similar porters, do these descriptions dovetail with your observations? Did the passage of time result in any noticible changes in the characteristics, mouthfeel or flavour of the beer?

b) In order to allow the beer to continue to condition, would it be better off in the refrigerator, on a shelf, or does it matter?

c) Where the slight over-carbonation is concerned, are there any remedies at this point? I've heard that time in the refrigerator eventually allows the beer to absorb some of the excess carbonation, but I do not know.

d) Does anyone see where I may have screwed up in a meaningful way? In your opinion, how did I do? Any advice for the future?

Thanks to all for the advice, assistance and encouragement. I'll be brewing my second beer on Tuesday (oatmeal cookie stout) and hope to continue the learning as well as the success.

Ron

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)