I am getting into all grain and want to build single tier stand.

I found this thread with a nice diagram of a stand: https://www.homebrewersassociation.org/forum/index.php?topic=13627.30

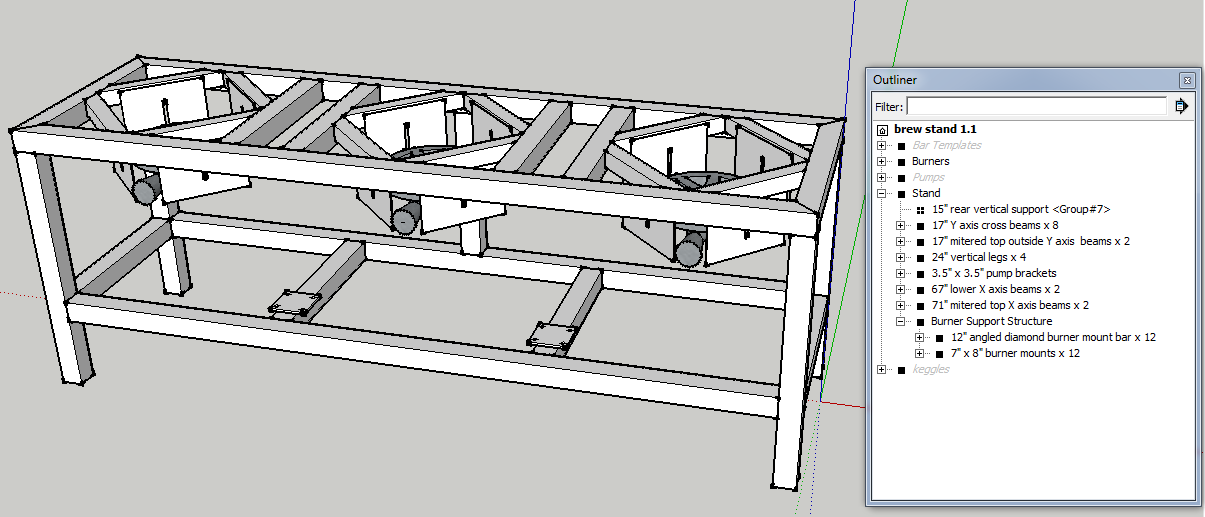

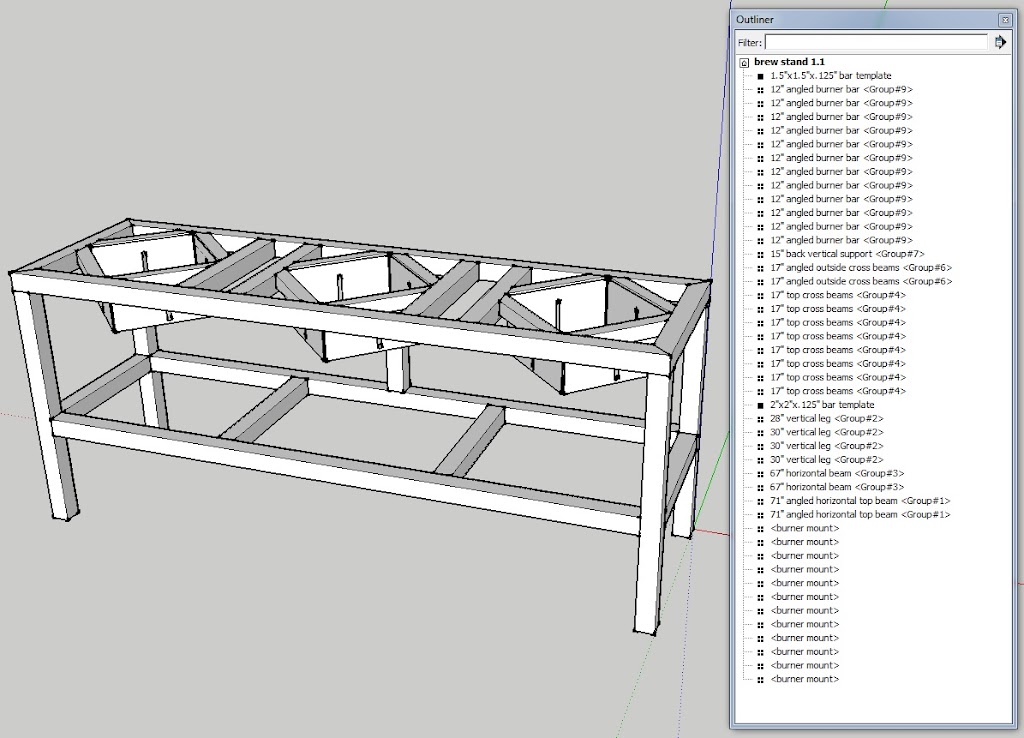

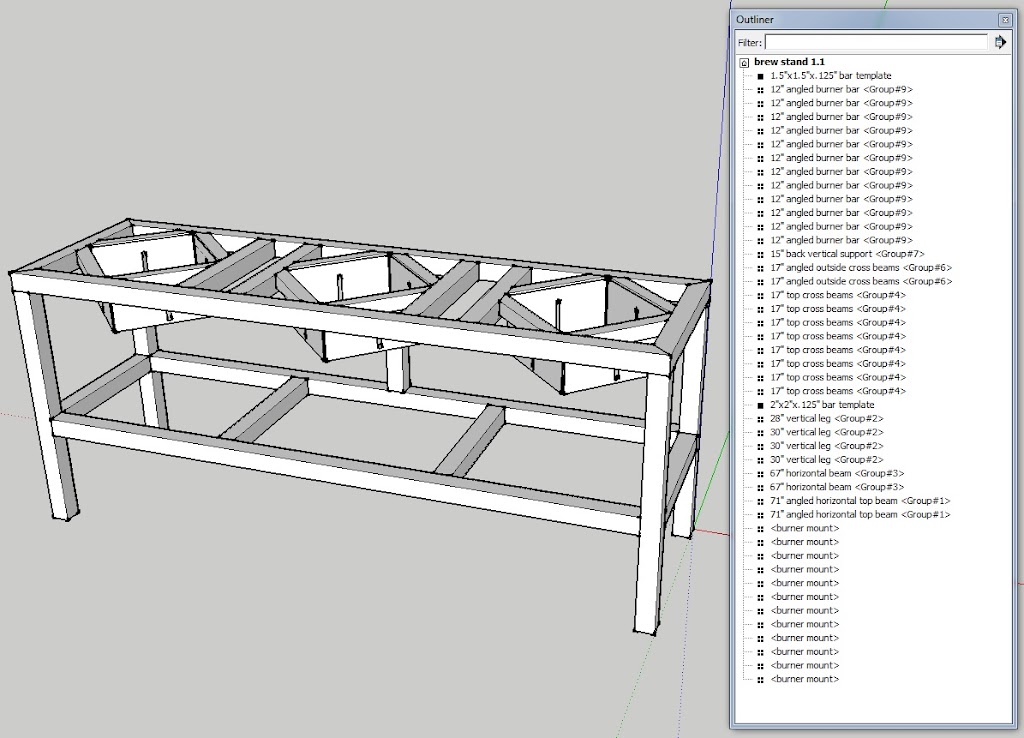

I cant seem to get a response from the OP in that thread to get the .skp file (3d model) so I just rebuilt it in sketchup, according to his specs in the above diagram.

I was hoping someone could provide feedback/answers on the stand

I will continue to post questions and evolve the model as I get feedback and answers.

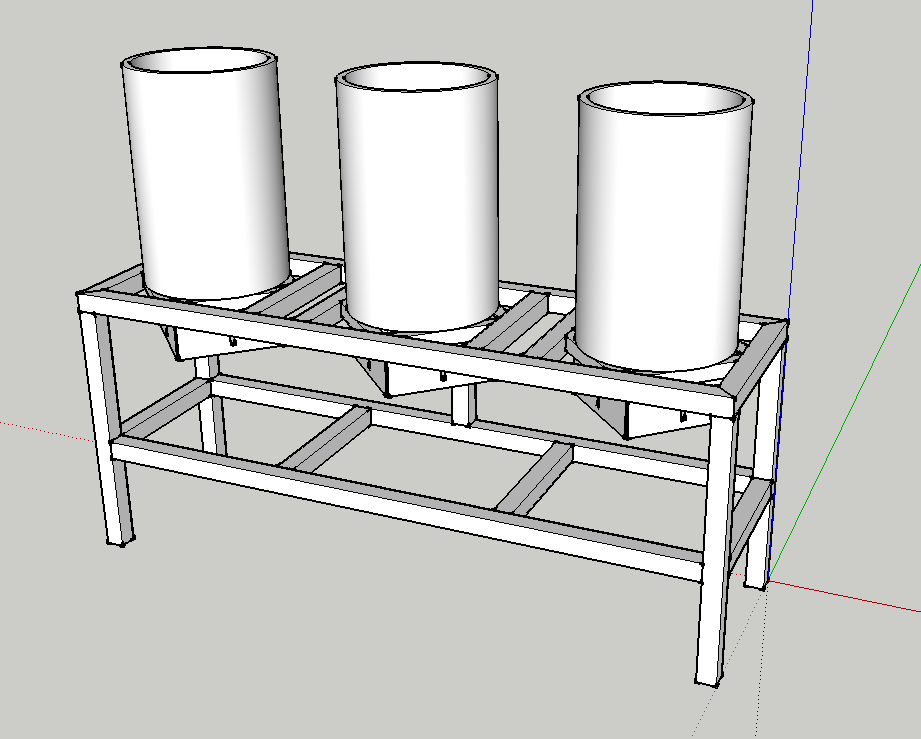

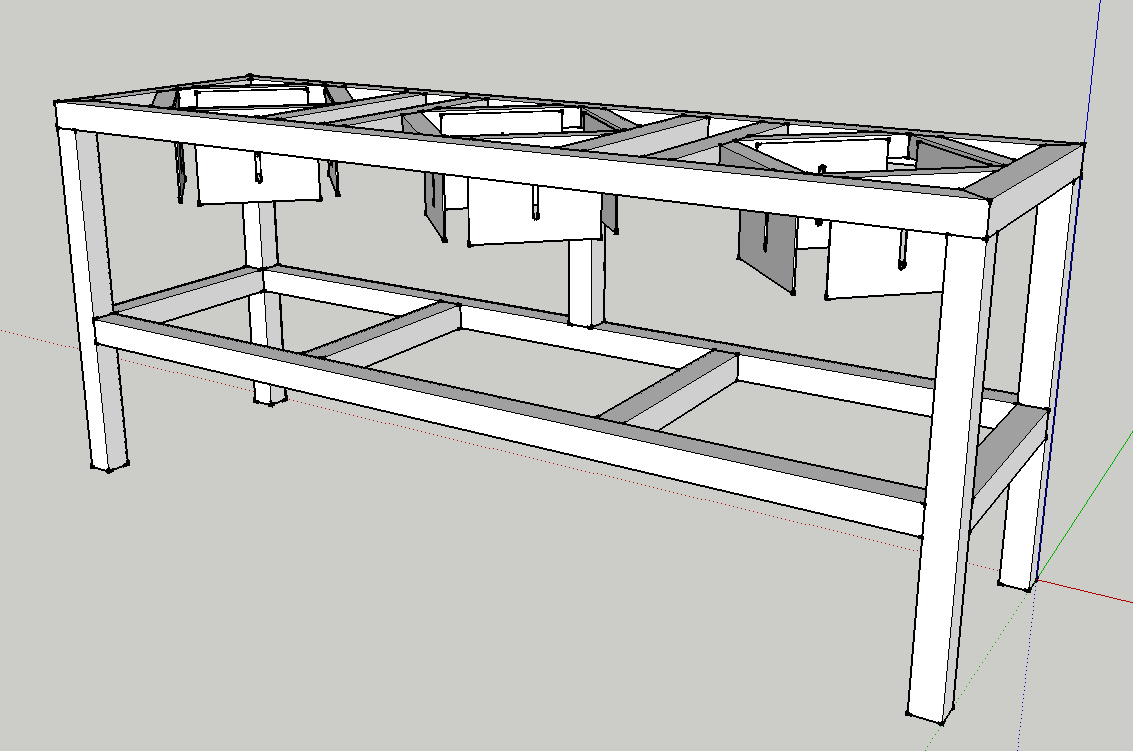

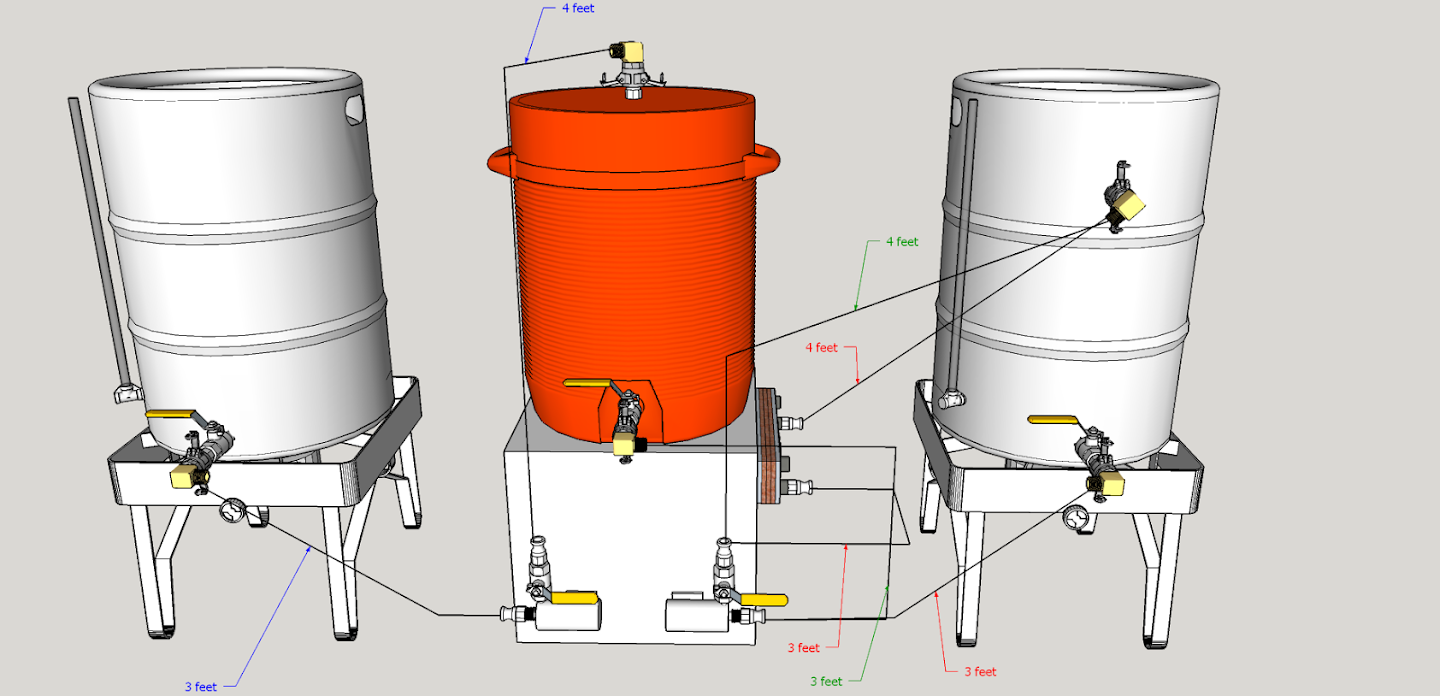

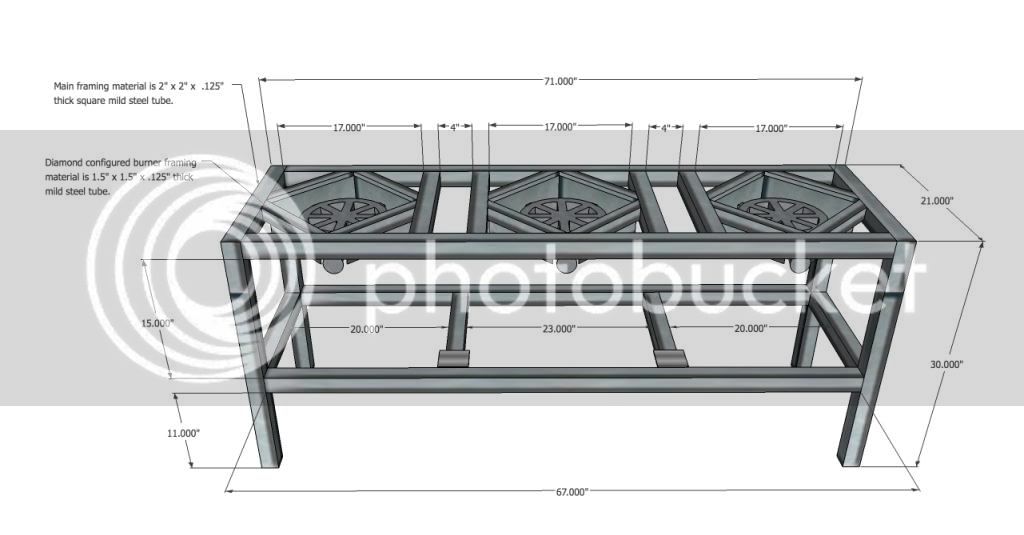

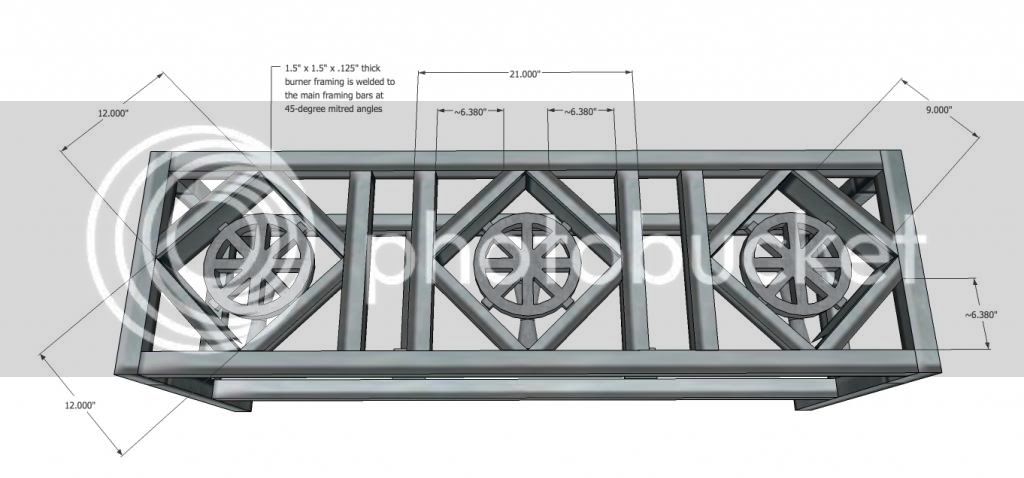

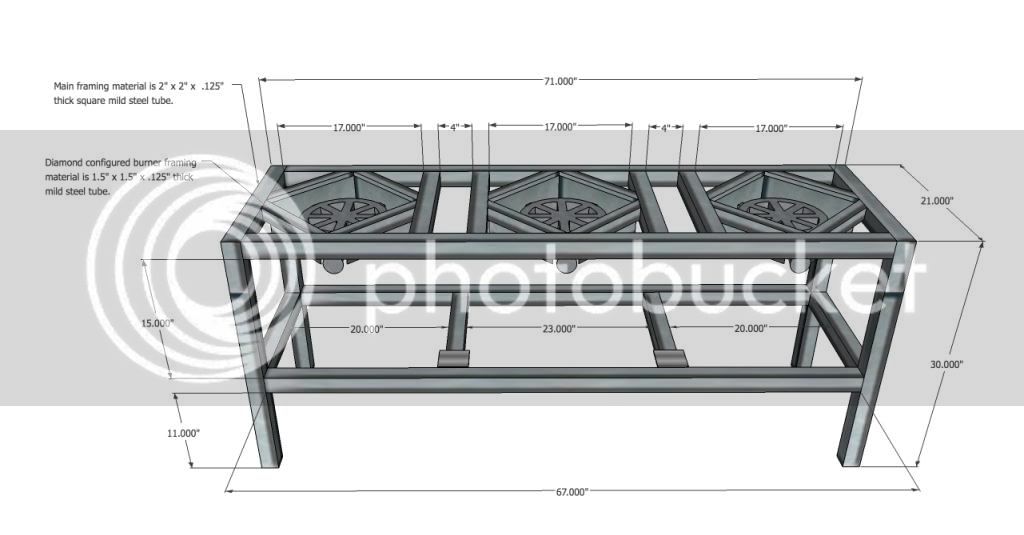

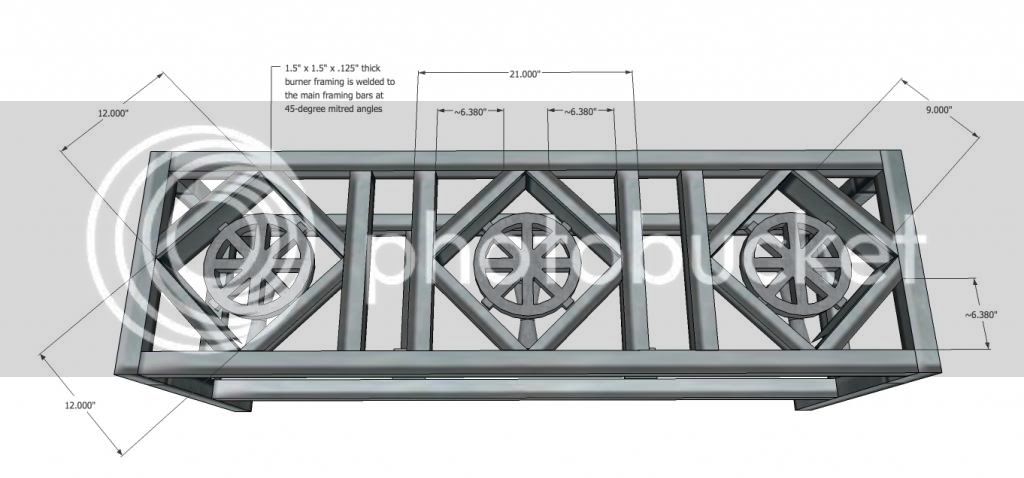

Here are a couple of sketches as it stands currently:

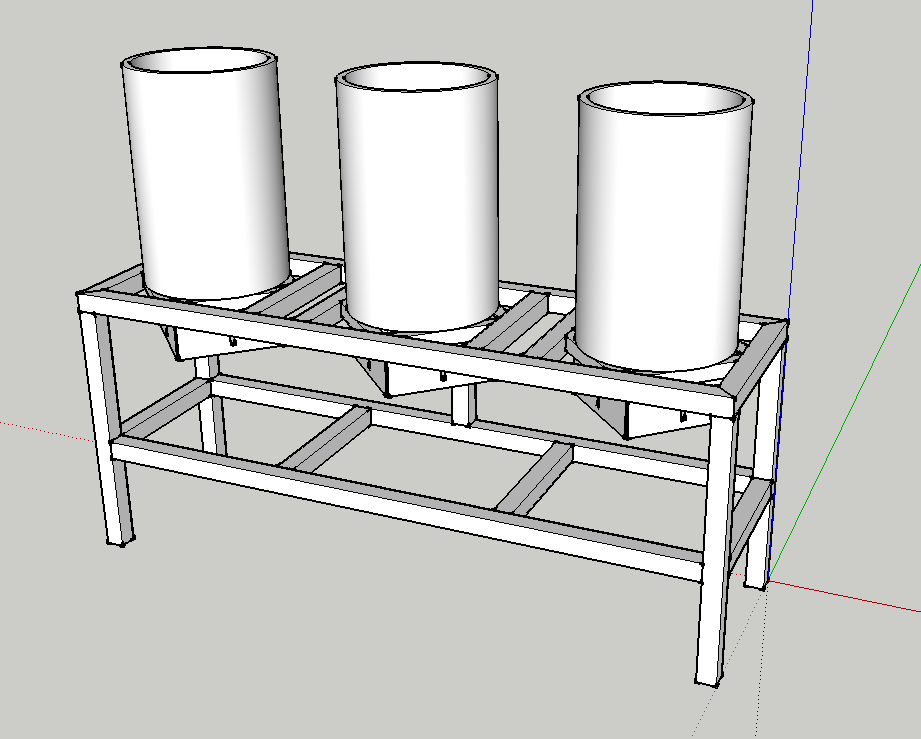

(with basic keggle dimensions)

I found this thread with a nice diagram of a stand: https://www.homebrewersassociation.org/forum/index.php?topic=13627.30

I cant seem to get a response from the OP in that thread to get the .skp file (3d model) so I just rebuilt it in sketchup, according to his specs in the above diagram.

I was hoping someone could provide feedback/answers on the stand

I will continue to post questions and evolve the model as I get feedback and answers.

Here are a couple of sketches as it stands currently:

(with basic keggle dimensions)