EmDubeu

Well-Known Member

- Joined

- Feb 21, 2013

- Messages

- 239

- Reaction score

- 46

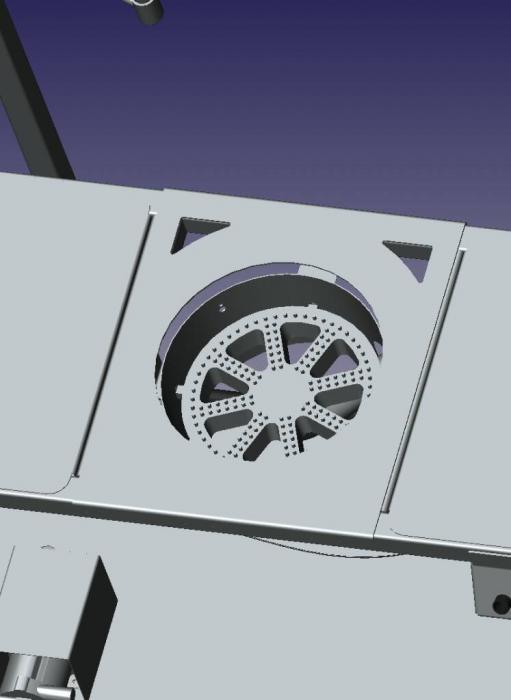

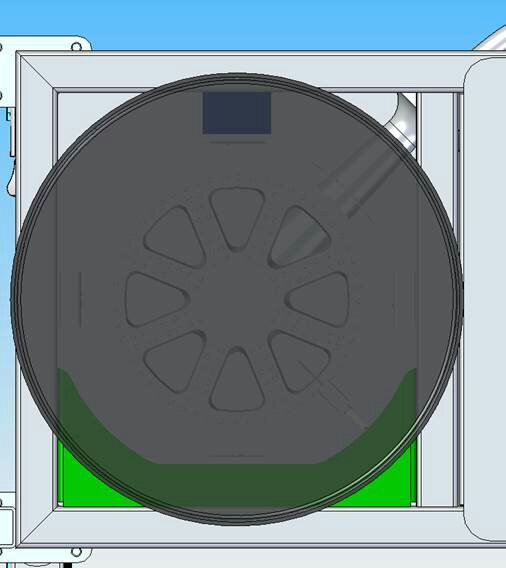

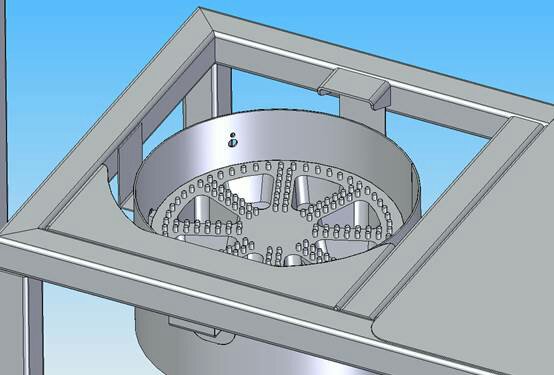

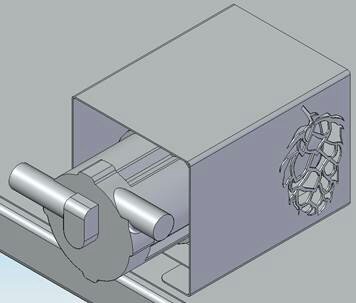

Laser cut and formed pump cover. Fits both Chugger and March pumps. I will post some other pics of the cover around a pump. No problems with pump over heating because of lack of air movement around the pump and cover. Take that, naysayers...

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)