bornandraisedlv

Well-Known Member

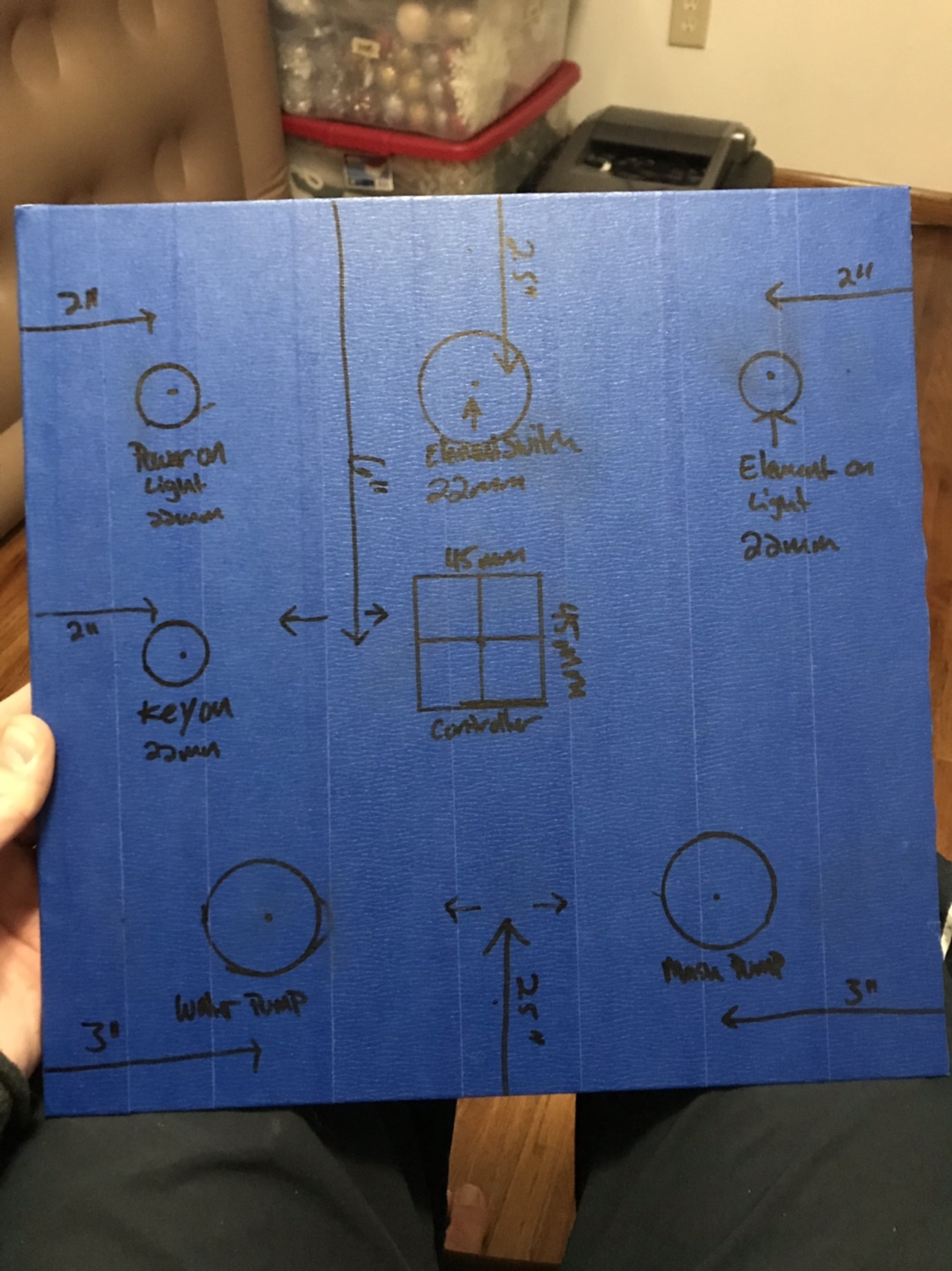

So I have ordered all of my parts and have my box and will be cutting everything out this weekend. My plans are at this moment to measure and draft everything out onto paper, make the cuts on the paper and then trace those cuts onto my panel.

As I have never done anything as plotted out as this I am looking for a little advice on the best way to go about getting the entire layout of my panel on it in a way that makes it easy to follow the lines and or center my drill bit on.

As I have never done anything as plotted out as this I am looking for a little advice on the best way to go about getting the entire layout of my panel on it in a way that makes it easy to follow the lines and or center my drill bit on.