21jason21

Well-Known Member

Just asked to join..

got you added! Thanks!

Just asked to join..

I don't plan to, I honestly think my Brew-Boss system is better. But I do have the latest version and it's not even 2 years old yet.

Facebook group is open. Just search Brew-Boss.

I'm definitely interested. Let us know.

Request submittedFacebook group is open. Just search Brew-Boss

I have to wonder what makes this pandemic so much worse than the ones in even the recent past that were about as bad. There were few closings etc. for those.... I think what is happening now might be necessary in the near future, but at present levels of infection I also think it is premature.

Hope you and all the other small business affected survive. Good luck.

This is Darin at Brew-Boss.

We no longer offer the budget 7" tablets. We only offer 10" tablets now and sell them at cost ($75). Out purpose is not to be a tablet supplier, but give people a reasonably priced Android tablet option if they don't already have one. We now use the iRULU X1s Lightning 10.1 Inch Google Android 4.4 KitKat Tablet PC, Octa Core, Multi-touch Display model. We have not heard of anyone having issues with these tablets. They are very fast and work really well in our experience. We also run a Brew on Premise where we have 6 Brew-Boss systems operating daily using the iRULU tablets and to date have never experienced a tablet related issue. We offer the tablet as an option, you can always buy your own tablet. We just don't want the cost of the tablet to overpower the cost of the Brew-Boss system.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

As a brew-boss owner and user for last few years i can say without a doubt it is a piece of cake to operate. There is a bit of a learning curve to get a perfectly scripted complex brew, but i was doing just fine on my first brew using a basic template.I've been wanting this system for a long time. I'm coming from a Zymatic and a Cooler and Pot prior to that.

I think the 15 Gallon fits my needs - 5 gallon batches of varying gravity with the occasional 8-9 gallon batch.

From watching the videos, the process looks pretty straight forward. The only hesitation I have is the controller. I'm not an engineer or IT

inclined so I'm not sure if the control panel will be difficult for me. I'd like to be able to set a delayed timer so that mash temp is ready in the am. Dough In, then Program the following steps: Multi-Step Mashes, Mash out, Heat to Boil, Circulate, Chill, pump out to fermenter. I'd like to be able to program those steps without banging my head against the wall. Is the panel difficult to operate?

As a brew-boss owner and user for last few years i can say without a doubt it is a piece of cake to operate. There is a bit of a learning curve to get a perfectly scripted complex brew, but i was doing just fine on my first brew using a basic template.

I find the Beersmith XML export imports into Brew-Boss work and give a fairly decent starting point, but i typically modify the steps beyond that import. I've sometimes had to manually do a step in the middle of the brew that wasn't programmed in, and it's very easy to do those. i.e. stop the pump for a bit while i stir the mash or adjust something, then turn it back on with the touch of a button on the tablet. Overall, I love my Brew-Boss and it strikes the perfect balance for me of having control over my brew and automation.

There is also this site, which is fairly easy to get the hang of on creating step files.

http://brewingintheburgh.com/brew-boss/index.html

Good luck. I highly recommend the system !!

Thanks! I'm getting real close to pulling the trigger.

My setup would be:

Preconfigured V3 Deluxe 15 Gallon 240V System

Inline GFCI

Whirlpool Boss

Curious how the Whirlpool Boss works and whether people are happy with it. If there are accessories or modifications that anyone feels

are indispensable let me know.

Good point on the COFI. I also tend to leave the lid off and stir the mash once in a while. I also throttle the valve to it so that I don't get wort spraying all over the sides (I typically do a 5 gallon batch in a 15 gallon kettle). My technique puts me in the upper 70's for efficiency according to BS3.

Incidently before using a hop-spider the swirl-boss did have a tendency to clog a bit with pellets. The spider fixed that.

Is that a DS18B20 on the Brew Boss? Since DS18B20's are serialized and the code is not open source, I wouldn't think it would do any good to build your own. No way for the BB software to read the new one.

You might just email [email protected] and ask them.

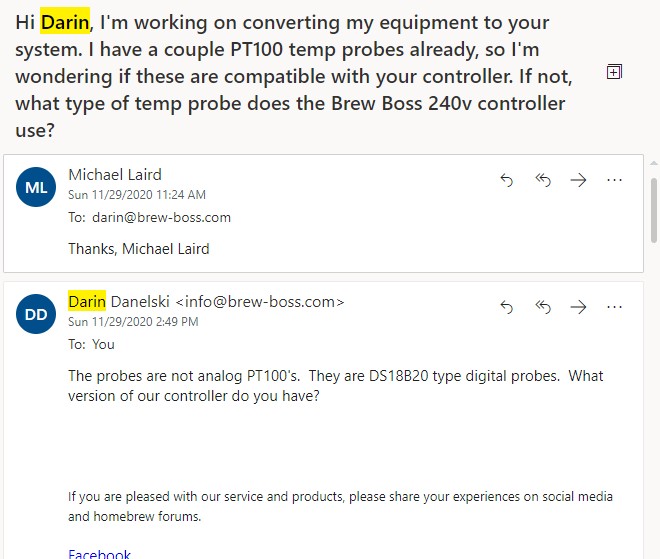

That's what Darin told me last year:

View attachment 752919

I don't think emails are getting through to that domain since they suspended operations...hopefully only temporarily. Are the DS18B20 serials married to the controller? How would you replace them when they fail?? I think the serials are mainly for multiple sensor systems, right?

No, sir.Yea, it would have to be by IO port/pin because from what I can tell you can't count on the order of received serial Ids when reading sensors on one pin. Either way, Darin seems to be doing something like this, since he provided a new sensor with no concern about serialization. Good to know.

@kc.rkitek don't suppose Darin gave you the wiring sset up for that 3.5 mm plug did he?

Do you have an email for Darin ?? I'd like to see if he has any of the grain baskets that were offered last September.To follow up on this, Darin replied to my email and besides this probe thing answered a few unrelated questions. He sold me a replacement probe, so it stands to reason that the serial of the ds18b20 doesn't matter..must be read dynamically since he made no mention of program changes, right?

Our probe may not work with other devices designed for a DS18B20 probe. Ours is custom made for us with a unique address range. Others have tried it unsuccessfully and have burned out our probe. So be careful.

The tip is Positive, the middle is data and the base is ground.

Darin

Thanks for that info. If the one I just bought from Darin fails, I may try to build the next. I'm also in the process of building a couple of Thorrak's brewpi-esp8266 controllers for my ferm chamber and keezer (just starting this). Ideally, every probe I have on hand would work on any of the devices...you know, in case of emergency.Here's what Darin told me when I asked about it way back in 2016:

That said, I have a brewpiless fermentation temp control system I built that works with the BrewBoss probe. I designed my system to use the same pinout so when I'm done brewing I can pull the probe from one system and plug it into the next and it's never been a problem. I've also used a probe I've built with the BrewBoss without any issues.

I put my 20 gallon brewboss in the basement right next to my ferment chamber and kegerator. I got the condenser attachment and do not have an exhaust hood. The condenser works fine and I don't need a fan. Brewboss is out of business as of Jan 2022.....but it may just be a temporary closure due to lack of supply on parts for Darin. There are other condensors in addition to the one he sells that also should work as long as you can add a camlock fitting to attach it to the kettle. If Darin is out of business permanently you may want to join the Brew-Boss Electric Brewing Users Group Facebook page.....for self service customer support.I love my Jaded Hydra. It does currently sit on the element without issue, but I am planning on fabricating something to support it so it doesn't potentially damage the element in the long run.

I'm not too worried about it, I'm renting.

Sometimes I move it under the garage door, but most of the time I just leave it where it is. When I buy a home I'm going to be building this system inside the house so I will have an exhaust fan at that point.

I used these in the 7/8" diameter: Food Safe Silicone Cutting Board Rubber Bumper Feet - All Sizes and Colors | eBayso my biggest issue I've run into is the little silicon feet on the bottom of the COFI basket... any idea where to get those if Darin is gone? those little f'n things break all the time.